Engine with double supercharging systems

An engine and dual supercharging technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of large knocking tendency, hindering the establishment of supercharging pressure, and deterioration of combustion, so as to widen the low-speed torque platform and avoid combustion Knocking, the effect of lowering the intake air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

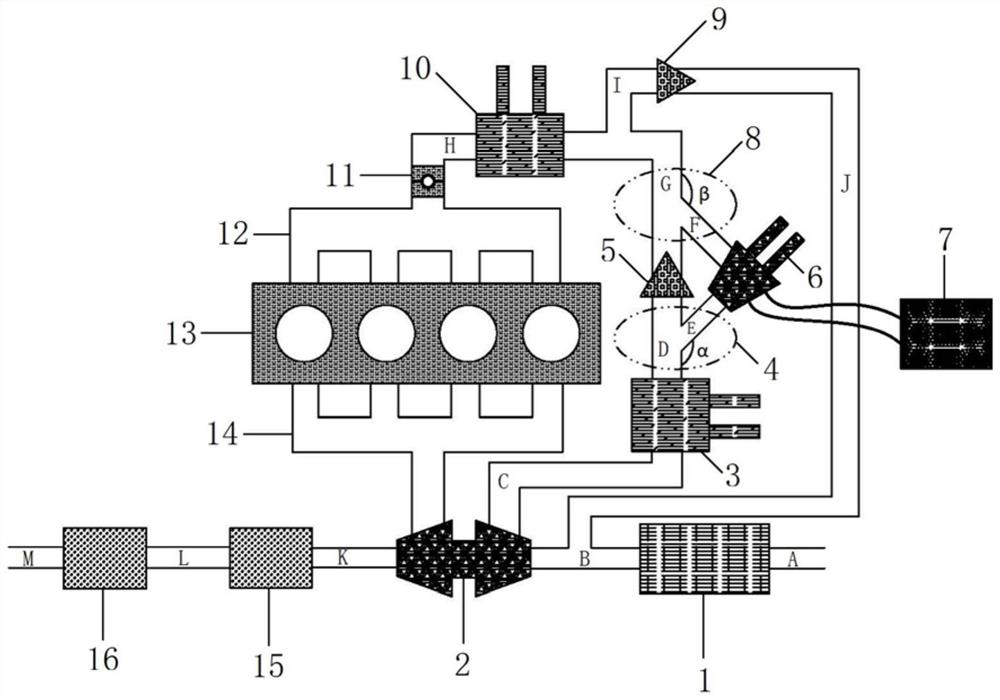

[0042] Please refer to the attached figure 1 , figure 1 It is a schematic diagram of the system architecture of an engine with a dual supercharging system in this embodiment. The engine with the dual supercharging system includes an air filter 1, a first supercharger 2, a first water-cooled intercooler 3, a first three-way pipe 4, a one-way valve 5, a second supercharger 6, Power supply 7, second three-way pipe 8, intake air recirculation valve 9, second water-cooled intercooler 10, throttle valve 11, intake manifold 12, engine body 13, exhaust manifold 14, front catalytic converter 15, Rear catalyst 16.

[0043] One end of the air filter 1 is connected to the A pipeline and the other end is connected to the B pipeline; one end of the B pipeline is connected to the air filter 1, and the other end is connected to the first supercharger 2. The first end of the first supercharger 2 is also connected to the first water-cooled intercooler 3 through the C pipeline; one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com