Improved combustion furnace

A combustion furnace and an improved technology, applied in the field of combustion furnaces, can solve the problems of inability to realize thermal energy recovery and utilization, energy waste, etc., and achieve the effects of strong practicability and functionality, improved utilization rate and strong functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

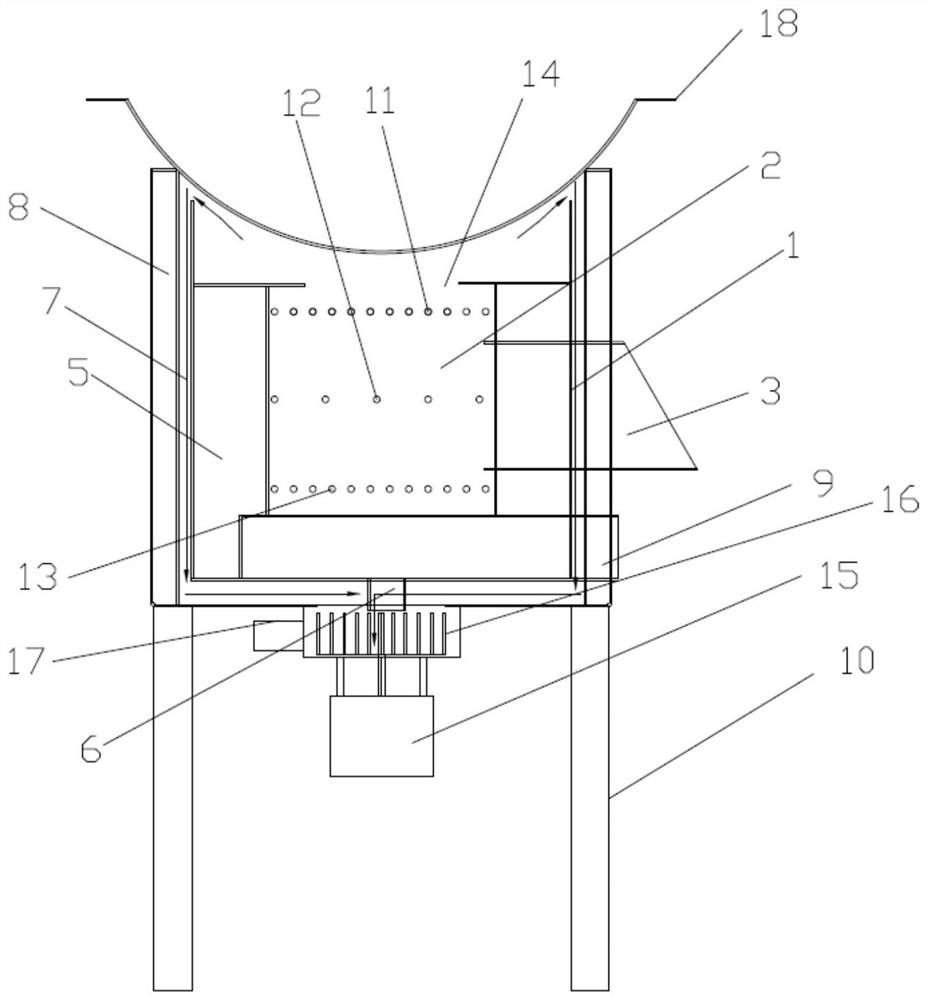

[0020] Attached below figure 1 The present invention is described in further detail.

[0021] An improved combustion furnace, comprising a furnace body 1, a furnace 2 located inside the body 1, and a slag outlet located at the lower part of the body 1, a gasification zone 5 is symmetrically arranged outside the furnace 2 and inside the body 1, and a gasification zone 5 is arranged symmetrically at the lower part of the body 1 There is a lower air inlet 6 connected with the gasification area 5, and the lower air inlet 6 is connected with an exhaust mechanism; the side of the gasification area 5 and away from the furnace 2 is provided with a return air heating area 7 connected with the furnace 2, and the return air is heated The outer side of the area 7 is provided with a thermal insulation layer 8; the lower part of the slag outlet is provided with an ash box 9, and the lower part of the main body 1 is provided with a foot 10.

[0022] The combustion furnace can use combustibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com