Extra-high voltage pipe gallery loop contact resistance test system

A technology of contact resistance and testing system, which is applied in the direction of grounding resistance measurement, measurement of resistance/reactance/impedance, and measurement devices, etc. It can solve the problems of large thermoelectric potential error of current sensor, inability to support contact resistance measurement, and small output capacity, etc., to achieve High precision, automatic measurement, low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

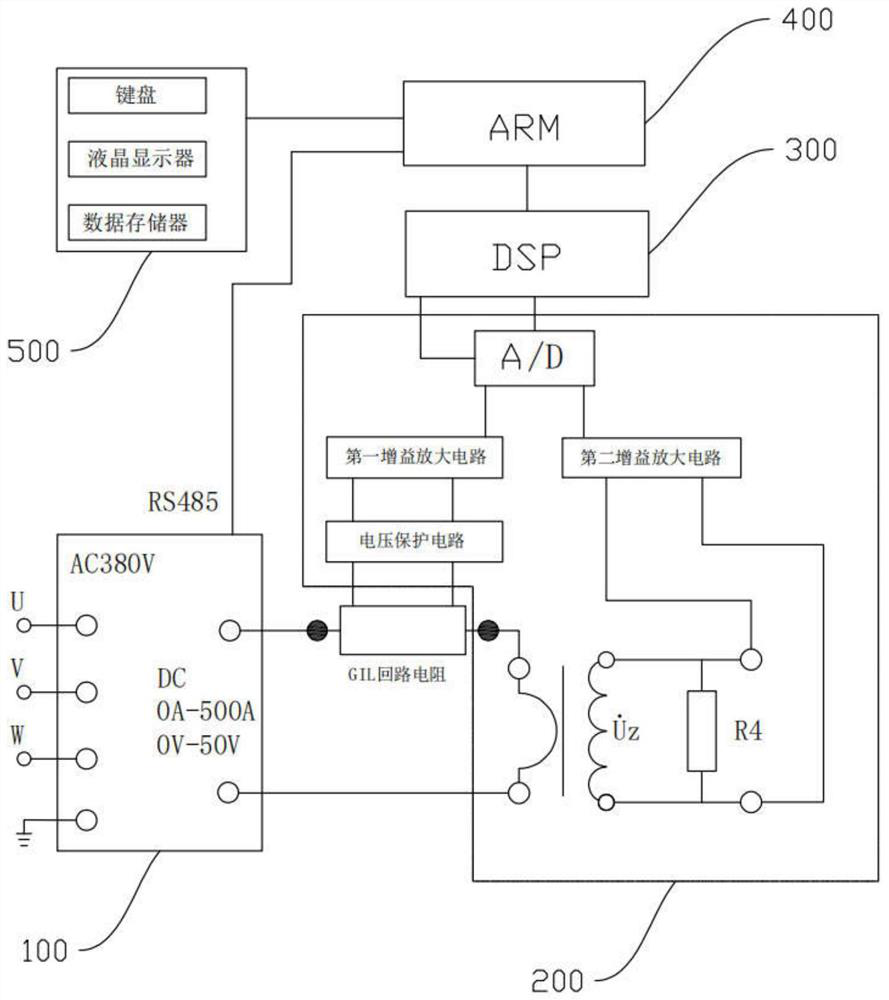

[0020] refer to figure 1 , according to the embodiment of the present invention, the contact resistance testing system of UHV pipeline gallery circuit includes a constant current source 100 , a sampling unit 200 , a data processing controller 300 , a main controller 400 and a human-computer interaction unit 500 . Wherein the human-computer interaction unit 500 and the data controller are electrically connected with the main controller 400, the input terminal of the sampling unit 200 is connected in series with the GIL main circuit to be tested and the constant current source 100 to form a loop, and the output terminal of the sampling unit 200 is connected with the data processing The controller 300 is electrically connected. The constant current source 100 is a program-controlled constant current source 100, electrically connected to the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com