Controller for ac rotary electric machine

A technology of rotating electrical machine and control device, which is applied in the direction of AC motor control, motor generator control, control of electromechanical transmission device, etc. Vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

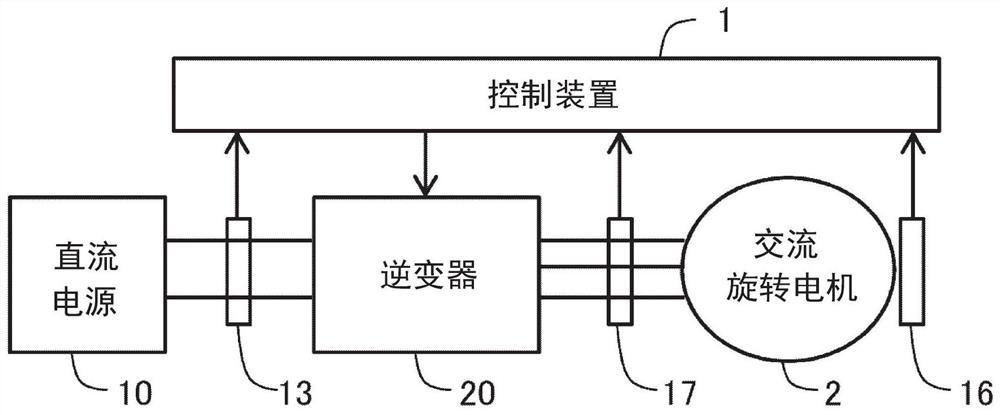

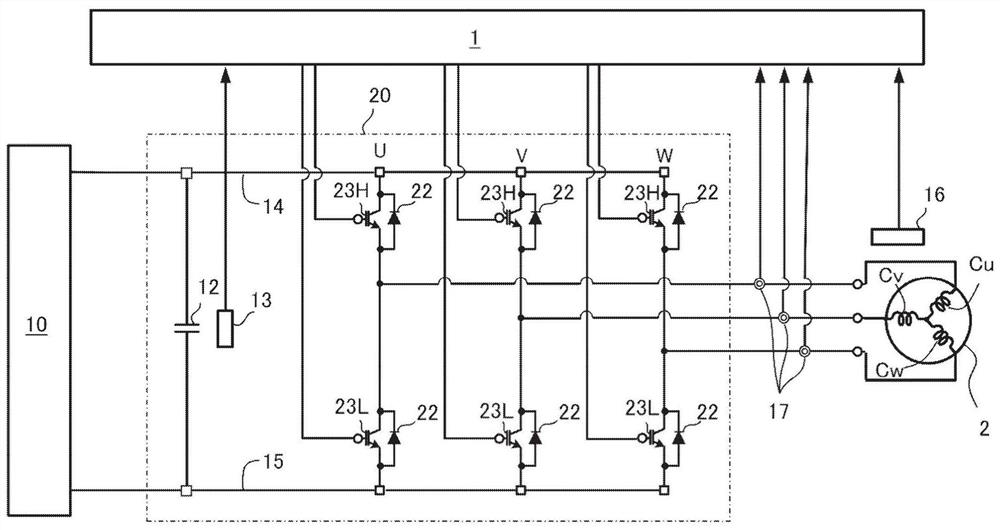

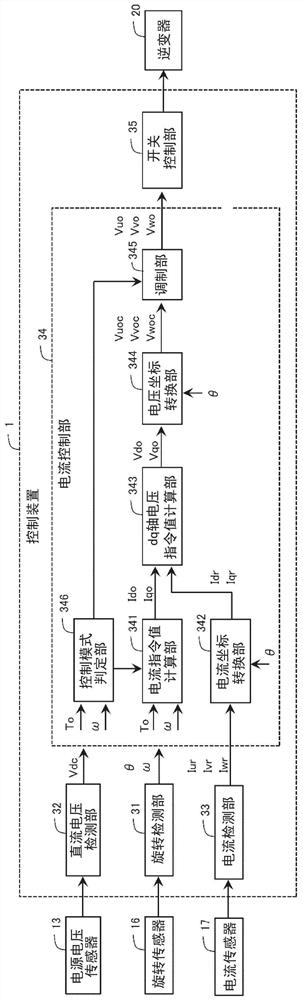

[0043] A control device 1 for an AC rotating electrical machine (hereinafter simply referred to as a control device 1 ) according to Embodiment 1 will be described with reference to the drawings. figure 1 and figure 2 It is a schematic configuration diagram of the AC rotating electrical machine 2 and the control device 1 according to the present embodiment.

[0044] 1-1. AC rotary motor

[0045] The AC rotating electric machine 2 has a stator provided with windings of a plurality of phases and a rotor provided with magnets. In the present embodiment, three-phase windings Cu, Cv, and Cw of U-phase, V-phase, and W-phase are provided. The 3-phase windings Cu, Cv, and Cw are star-connected. In addition, 3-phase windings can also be connected in delta. The AC rotating electrical machine 2 is a permanent magnet type synchronous rotating electrical machine, and a permanent magnet is provided in a rotor. In this embodiment, permanent magnets are embedded inside the magnetic stee...

Embodiment approach 2

[0113] The AC rotating electric machine 2 and the control device 1 according to Embodiment 2 will be described. The description of the same structural parts as those in the first embodiment described above is omitted. The basic configurations of the AC rotating electric machine 2 and the control device 1 of this embodiment are the same as those of Embodiment 1, but differ from Embodiment 1 in that a DC booster 40 is provided, and in the voltage increase mode, the DC voltage Vdc is changed by DC booster 40 boosts the voltage. Figure 14 It is a schematic configuration diagram of the AC rotating electrical machine 2 and the control device 1 according to the present embodiment.

[0114] A DC booster 40 for boosting the DC voltage Vdc is provided between the DC power supply 10 and the inverter 20 . A DC-DC converter such as a step-up chopper circuit is used as the DC booster 40 to boost the DC voltage output from the DC power supply 10 and supply it to the inverter 20 .

[0115...

Embodiment approach 3

[0126] The AC rotating electrical machine 2 and the control device 1 according to Embodiment 3 will be described. The description of the same structural parts as those in the first embodiment described above is omitted. The basic structure of the AC rotating electrical machine 2 and the control device 1 of this embodiment is the same as that of Embodiment 1, but the difference from Embodiment 1 is that it has an AC booster 50, and in the voltage increase mode, the AC booster The converter 50 boosts the voltage applied to the three-phase winding. Figure 16 It is a schematic configuration diagram of the AC rotating electrical machine 2 and the control device 1 according to the present embodiment.

[0127] An AC booster 50 for boosting the AC applied voltage of each phase is provided between the inverter 20 and the three-phase windings of the AC rotating electrical machine 2 . For example, a wiper resistor regulator capable of changing the boost rate is used for the AC booster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com