Method for treating lead plaster through top side smelting

A waste lead plaster and furnace top technology, which is applied in the field of metallurgy, can solve the problems of complex process methods, low lead yield, and high processing cost, and achieve the effects of compact process flow, improved lead yield, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

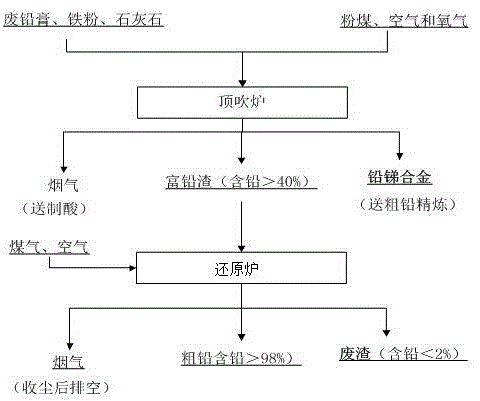

Image

Examples

Embodiment 1

[0037]1) Mix waste lead plaster, iron powder, and limestone according to the weight ratio of 100:8:5, and granulate them into pellets with a particle size of 8mm and a water content of 6% through cylinder granulation; iron powder is added to improve the slag shape, Limestone is used as a slagging agent. The main components of the waste lead plaster are 60% lead, 5% antimony, and 8% sulfur. The iron powder contains 99% Fe, and the limestone contains CaCO 3 82%;

[0038] 2) Send the pellets obtained in step (1) continuously and evenly to the top-blowing furnace with a belt conveyor, the amount of pellets added is 20t / h, and then spray pulverized coal and oxygen-enriched air from the top-blowing furnace top spray gun In, the furnace top spray gun is a liftable furnace top spray gun installed vertically on the furnace roof, the pulverized coal addition is 15% of the pellet addition, and the pulverized coal particle size is -200 mesh 90%, which contains 70% carbon, 0.1% sulfur, 15...

Embodiment 2

[0043] 1) Mix waste lead plaster, iron powder, and limestone according to the weight ratio of 100:5:3, and granulate them into pellets with a particle size of 5mm and a water content of 4.5% through cylinder granulation; iron powder is added to improve the slag shape, Limestone is used as a slagging agent. The main components of the waste lead plaster are 75% lead, 3% antimony, and 5% sulfur. The iron powder contains 98.5% Fe, and the limestone contains CaCO 3 81%;

[0044] 2) Send the pellets obtained in step (1) continuously and evenly to the top-blowing furnace with a belt conveyor, the amount of pellets added is 30t / h, and then spray pulverized coal and oxygen-enriched air together from the top-blowing furnace top-blowing furnace In, the furnace top spray gun is a liftable furnace top spray gun arranged perpendicular to the furnace roof, the pulverized coal addition is 9% of the pellet addition, and the pulverized coal particle size is about 85% of -200 mesh, wherein Carb...

Embodiment 3

[0049] 1) Mix waste lead plaster, iron powder, and limestone according to the weight ratio of 100:2:1, and granulate them into pellets with a particle size of 2mm and a water content of 3% through cylinder granulation; iron powder is added to improve the slag shape, Limestone is used as a slagging agent. The main components of the waste lead plaster are 90% lead, 1% antimony, and 2% sulfur. The iron powder contains 98% Fe, and the limestone contains CaCO 3 80%;

[0050] 2) Send the pellets obtained in step (1) continuously and evenly to the top-blowing furnace with a belt conveyor, the amount of pellets added is 40t / h, and then spray pulverized coal and oxygen-enriched air together from the top-blowing furnace top-blowing furnace In, the furnace top spray gun is a liftable furnace top spray gun arranged perpendicular to the furnace roof, the pulverized coal addition is 3% of the pellet addition, and the pulverized coal particle size is -200 mesh 80%, which contains 50% carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com