High-speed bill printing press clutch pressure control based on complex programmable logic device (CPLD) and feedback method based on CPLD

A banknote printing machine, clutch pressure technology, applied in the direction of computer control, program control, general control system, etc., can solve the problems that can not guarantee the complete avoidance of the clutch pressure problem, to achieve high real-time performance, improve real-time performance, reduce the lead Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below in conjunction with accompanying drawing and embodiment;

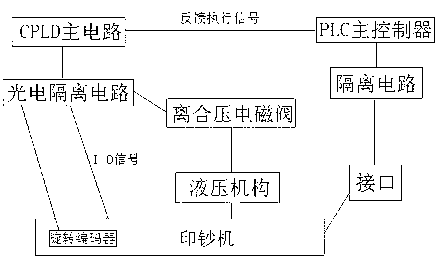

[0012] 1. If image 3 , design and develop CPLD main circuit, write VHDL program and download it to CPLD according to the requirements of the clutch pressure process of banknote printing machine, modify the original PLC program, strip off the clutch pressure function, and completely take over its function by the CPLD embedded system.

[0013] 2. Through the photoelectric isolation circuit, I / O signals such as the photoelectric pulse of the front regulation and the pressure detection of the hydraulic mechanism from the banknote printing machine are obtained.

[0014] 3. Through the photoelectric isolation circuit, the rotary encoder signal installed on the main shaft of the banknote printing machine is obtained, and converted into the synchronous angle signal of the banknote printing machine after calculation, and the instantaneous printing speed of the bankn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com