Full-automatic milk tea brewing and blending machine

A fully automatic, brewing technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of inability to configure ingredients, large flow of personnel, and errors in ingredients, reducing manual intervention, saving labor costs, Reduce the effect of feeding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

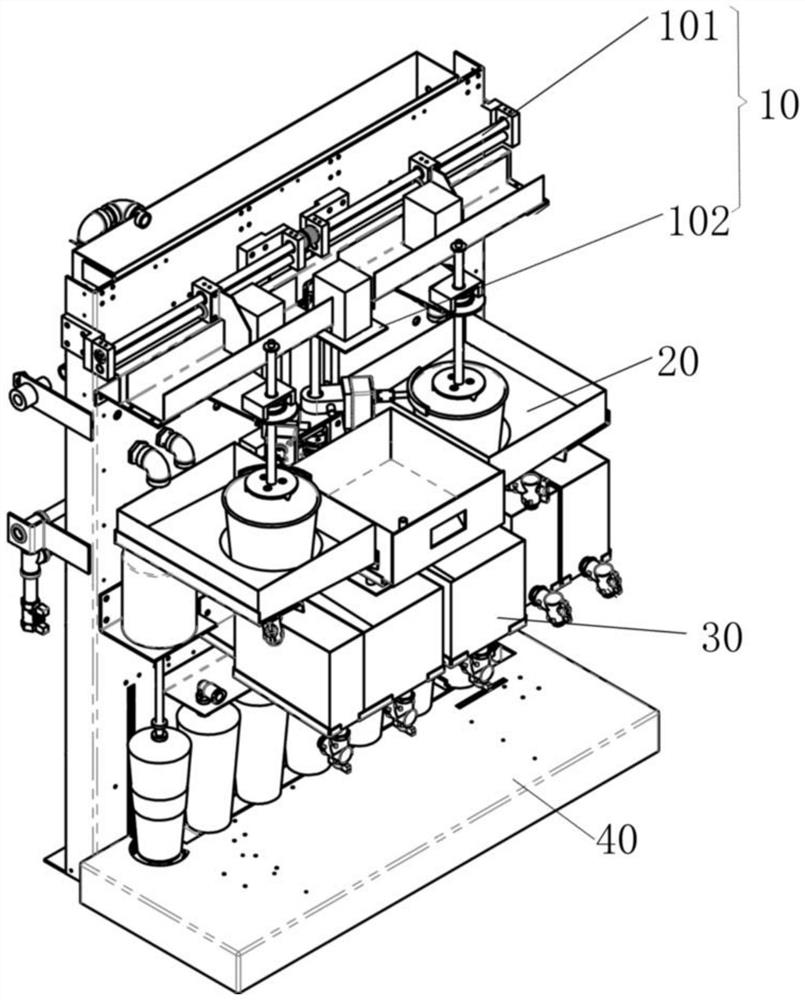

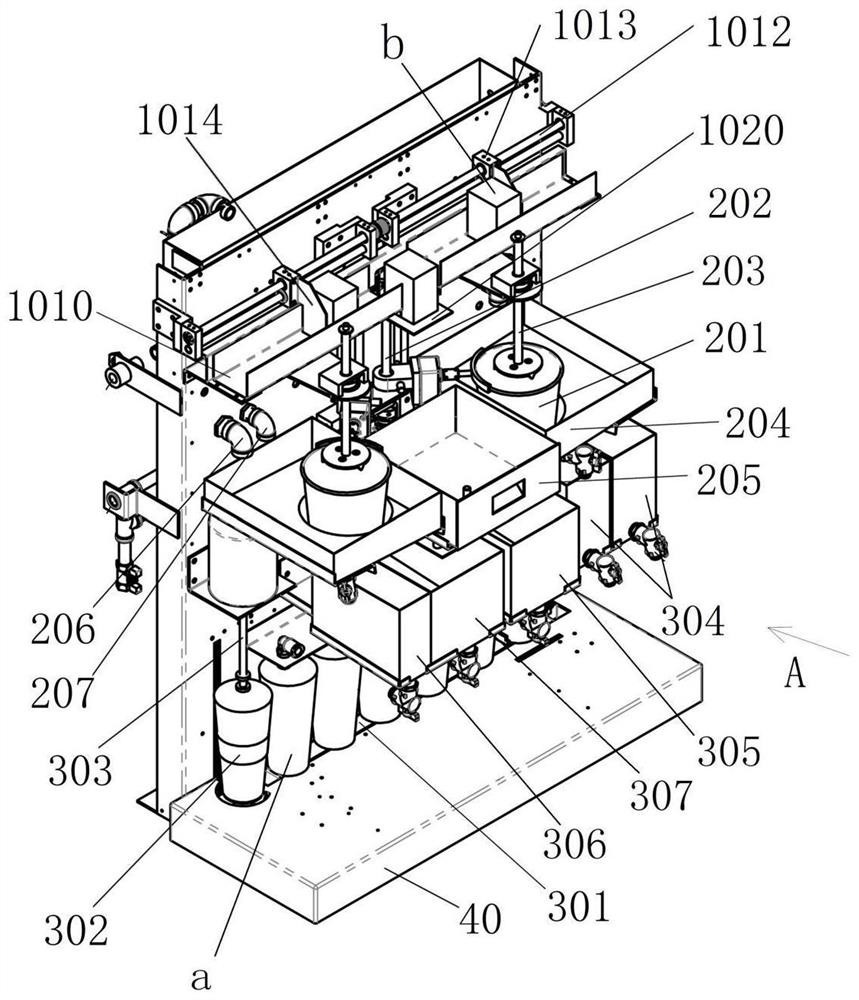

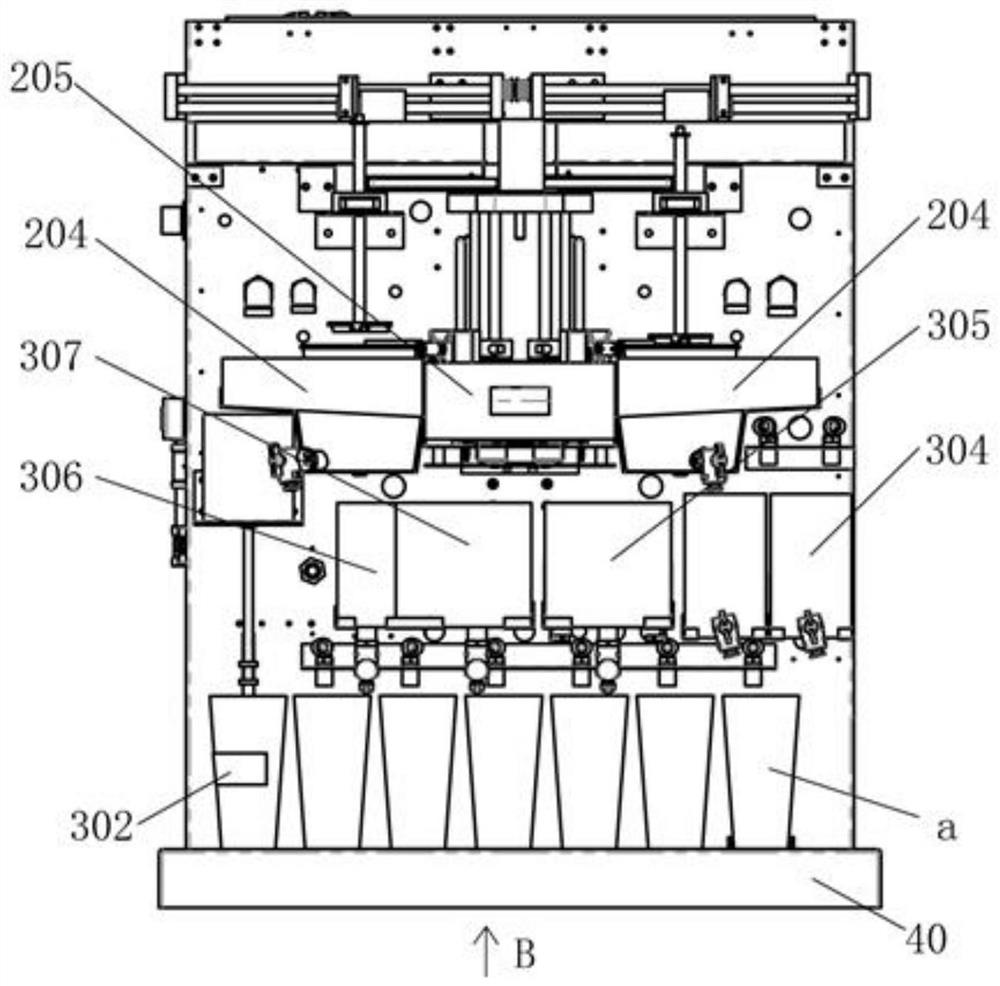

[0043] As attached to the manual Figure 1-12 As shown, as a specific embodiment of the present invention, the specific structure of the present invention is: a kind of fully automatic milk tea brewing blending machine, comprises material conveying mechanism 10 and frame 40, and the discharge end of material conveying mechanism 10 is provided with punching machine. The brewing mechanism 20 is provided with a batching mechanism 30 at the discharge end of the brewing mechanism 20, and the feeding mechanism 10, the brewing mechanism 20, and the batching mechanism 30 are fixedly arranged on the frame 40 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com