Movable slurry material treatment device

A processing device, mobile technology, applied in the direction of mixers, dissolvers, mixers with rotating stirring devices, etc., can solve the problems of wasting working time and low efficiency, and achieve time-saving, flexible and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

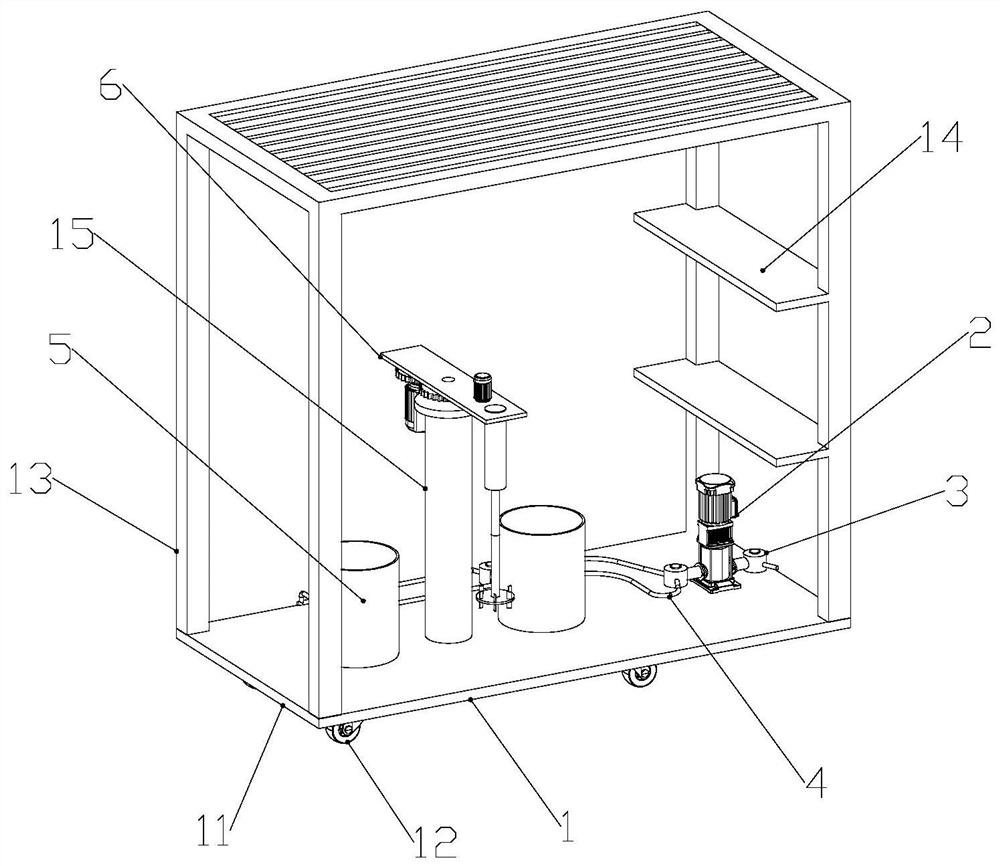

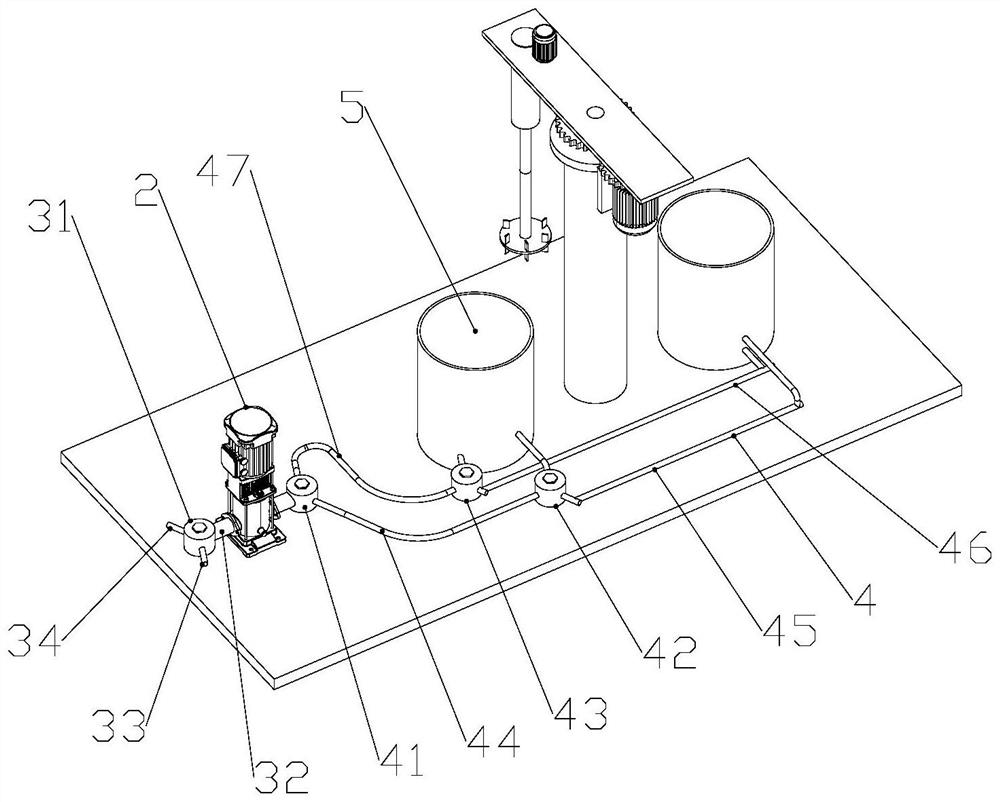

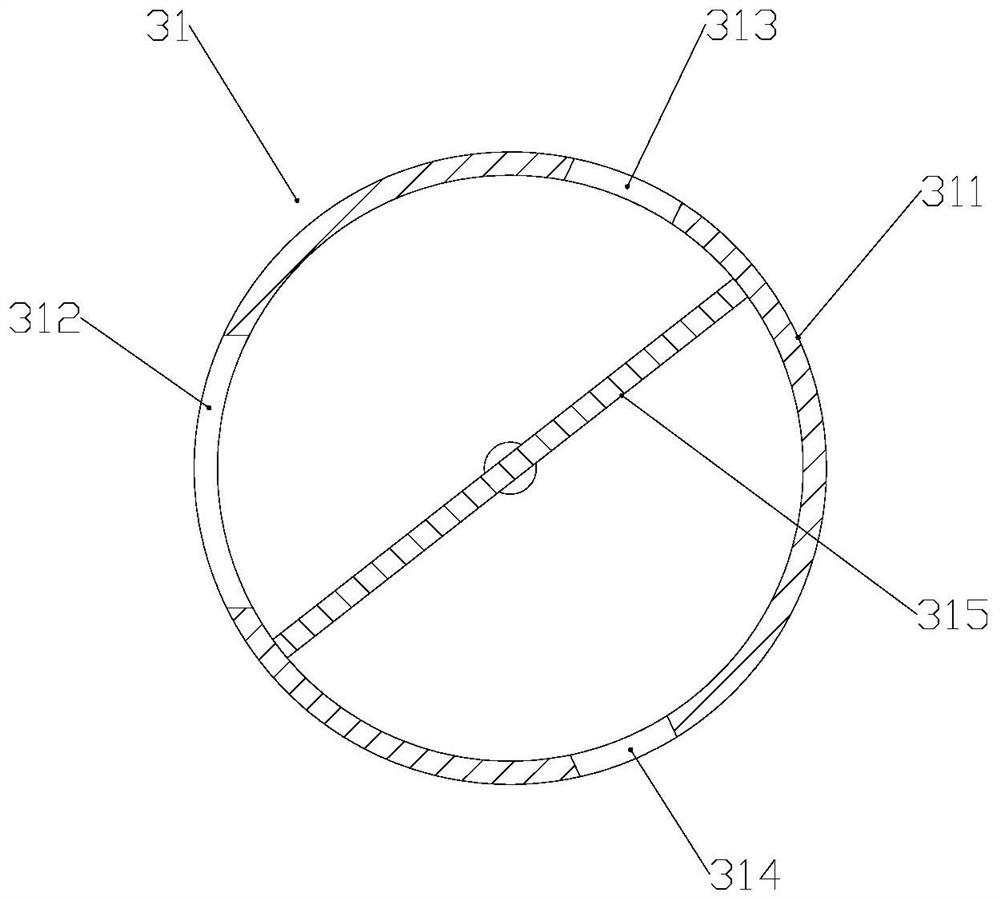

[0026] A movable slurry material processing device, the processing device includes a moving part 1, such as figure 1 As shown, the moving part 1 is provided with a pump body 2, one side of the pump body 2 is connected with a first control part 3, the other side of the pump body 2 is connected with a feeding part 4, and the top of the moving part 1 is provided with a symmetrical Distributed mixing barrel 5, the bottom of the mixing barrel 5 is equipped with a weighing sensor, the weighing sensor is used to control the weight of the material, when the set threshold is reached, the corresponding auxiliary materials are added to the mixing barrel 5, the moving part 1 and the mixing barrel 5 are connected by weighing sensors, and stirring pieces 6 are arranged between the symmetrically distributed mixing barrels 5 .

[0027] The moving part 1 comprises a moving seat 11, such as figure 1 , Figure 4 As shown, a wheel hub 12 is provided under the moving seat 11. By setting the whee...

Embodiment 2

[0036] The mixing tank can be flushed by passing the feed pipe 33 through clean water, through the positive and negative rotation of the pump body 2, and cooperating with the control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com