Magnesium-aluminum alloy plate softening method

A magnesium-aluminum alloy, friction block technology, applied in metal processing equipment, forming tools, feeding devices, etc., can solve the problem of uneven thickness, achieve effective and thorough softening, and overcome uneven heating and softening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0041] This embodiment is an embodiment of a flattening and straightening device for a magnesium-aluminum alloy plate.

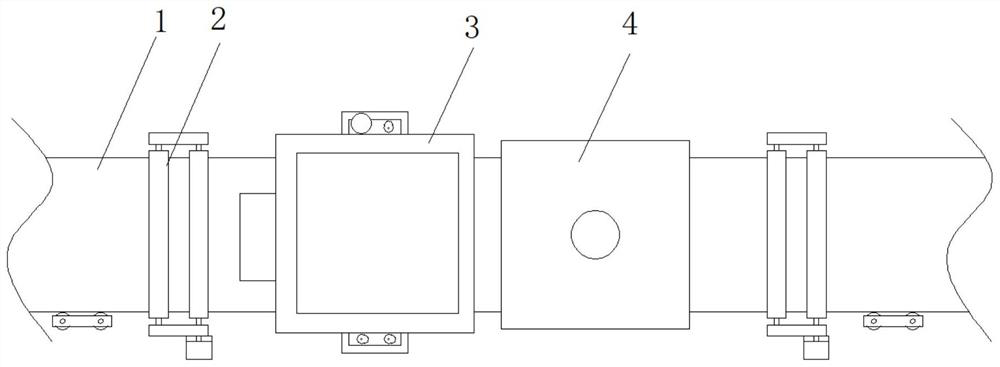

[0042] like figure 1 , 2, 8, 9, 10, and 11, a magnesium-aluminum alloy plate flattening and straightening device disclosed in this embodiment includes a transmission member 2, a friction member 3, and a flattening member 4; the magnesium-aluminum alloy plate 1 can be Intermittent movement is carried out under the action of a plurality of transmission members 2, and friction members 3 and flattening members 4 are sequentially arranged along the moving direction of the magnesium-aluminum alloy plate 1, and the friction members 3 and flattening members 4 are symmetrically arranged on the magnesium-aluminum alloy plate 1. On both sides of the plate 1, and against the magnesium-aluminum alloy plate 1, the friction member 3 can adapt to the uneven surface of the magnesium-aluminum alloy plate 1, completely and thoroughly rub the uneven magnesium-aluminum alloy pl...

specific Embodiment approach 2

[0048] This embodiment is an embodiment of a method for flattening and straightening a magnesium-aluminum alloy plate.

[0049] A method for flattening and straightening a magnesium-aluminum alloy plate disclosed in this embodiment includes the following steps:

[0050] Step a, parameter adjustment, according to the thickness of the magnesium-aluminum alloy plate 1 to be flattened and corrected, three parameters are set:

[0051] Parameter 1. The vibration time T of the exciter 3-10;

[0052] Parameter two, the rotational speed of pushing motor 4-9;

[0053] Parameter 3, the intermittent transmission interval of transmission member 2 is T1;

[0054] Step b, install the plate, pass one end of the strip-shaped magnesium-aluminum alloy plate 1 that needs to be flattened and corrected sequentially through the initial transmission member 2, the symmetrically arranged friction member 3, the symmetrically arranged flattened member 4 and the next transmission member 2, to complete ...

specific Embodiment approach 3

[0059] This embodiment is an embodiment of a friction member for flattening and correcting a magnesium-aluminum alloy plate.

[0060] It should be noted that the friction member for flattening and straightening of magnesium-aluminum alloy plates in this embodiment can be implemented alone, that is, as a part of a flattening and straightening device for magnesium-aluminum alloy plates, or it can be used in the embodiment A flattening and straightening device for a magnesium-aluminum alloy plate is further defined.

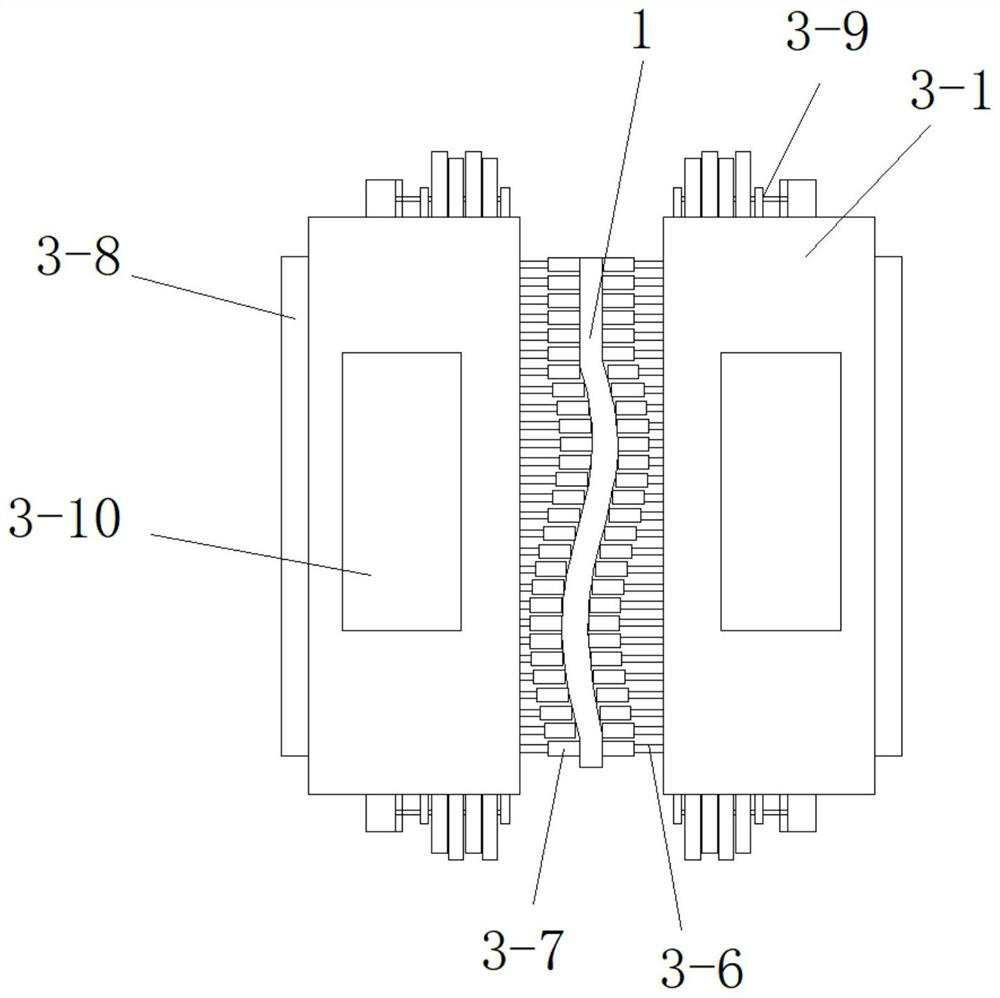

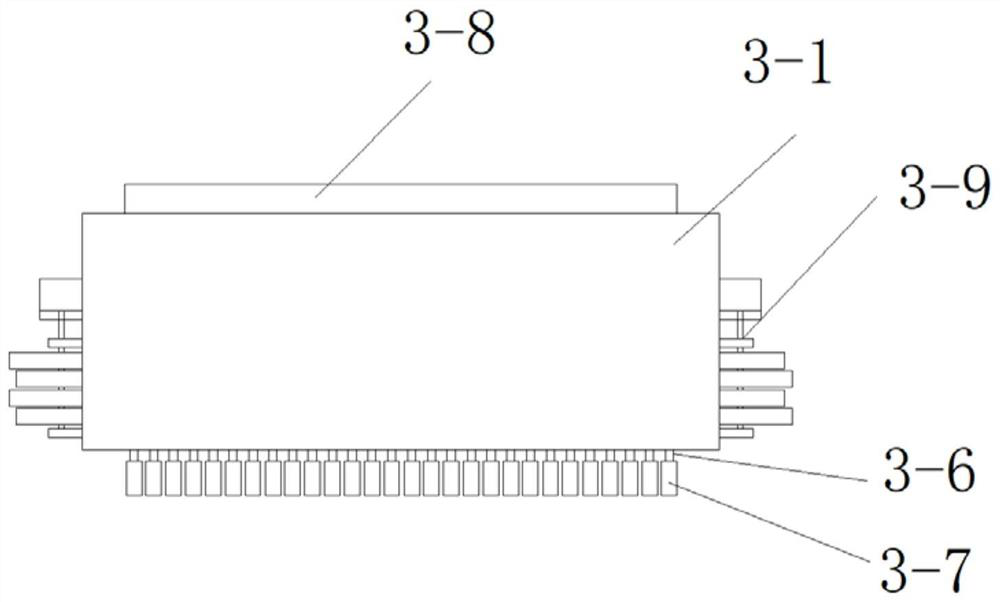

[0061] combine Figure 1-7 As shown, a friction member for flattening and correcting magnesium-aluminum alloy plates disclosed in this embodiment is characterized in that it includes a friction box 3-1, a limit plate 3-2, a splint 3-3, and a magnetic block 3-4 , positioning rod shaft 3-6, friction block 3-7, electromagnet disk 3-8, position adjustment group 3-9 and vibrator 3-10; the friction box 3-1 is provided with a limiting plate 3-2 , the friction box 3-1 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com