Fixing device for projectile product cabin section welding

A technology of fixing device and rocket chamber, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor operation comfort, difficult to control the lifting speed, and the height of the operation position is not adjustable, so as to improve the comfort and reduce the The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

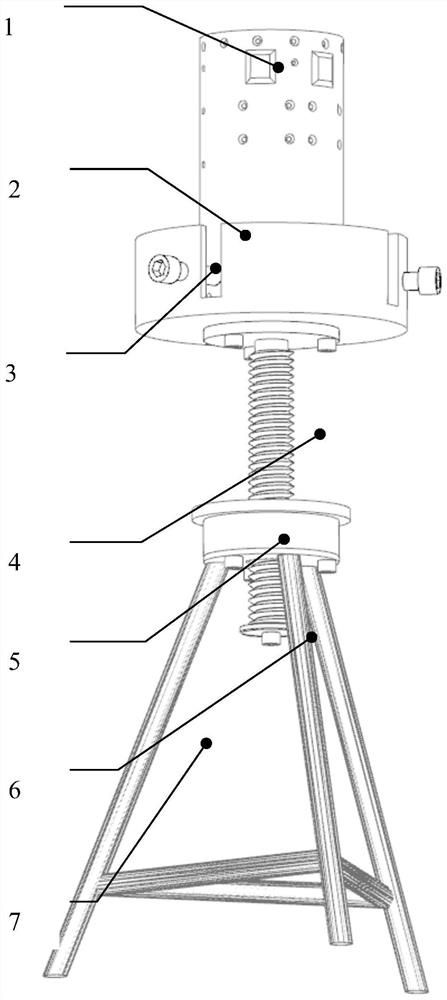

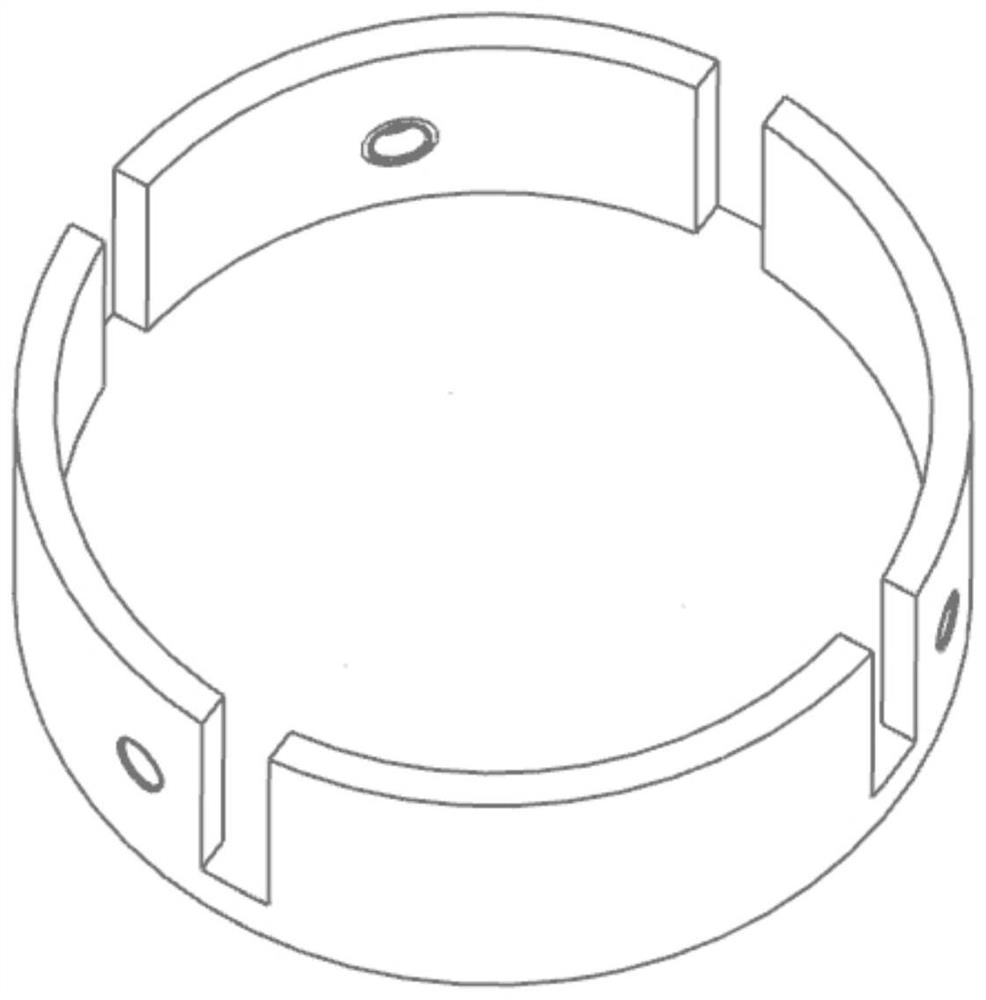

[0049] In this example, if Figure 1-Figure 7As shown, when a certain type of anti-aircraft missile instrument cabin 1 needs to be butt welded, the instrument cabin 1 is first placed on the tray 2, and the three fastening screws 3 are adjusted according to the outer diameter of the cabin to lock the cabin to prevent slipping. The rubber pad at the end of the fixing screw 3 can compress the cabin body without scratching the outer surface of the cabin body, which is simple, reliable and easy to operate. Then, according to their own conditions, the operator rotates the tray 2 clockwise or counterclockwise, and uses the threaded connection between the screw rod 4 and the base 5 to adjust and lock the height of the tray 2 to meet his own comfort requirements. Compared with the lifting method, the cost is low, reliable, and the lifting and locking operations are convenient. When the highest height is reached, the function of the baffle 6 is used to prevent the screw 4 from the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com