Anti-static and anti-explosion thermal insulation material for deep sea platform

An insulation material and anti-static technology, applied in the field of deep-sea platforms, can solve problems such as easy to absorb dust, poor anti-static and thermal insulation performance, and affect the performance of explosion-proof insulation materials, so as to achieve easy transportation, good anti-static effect, and increase explosion-proof insulation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

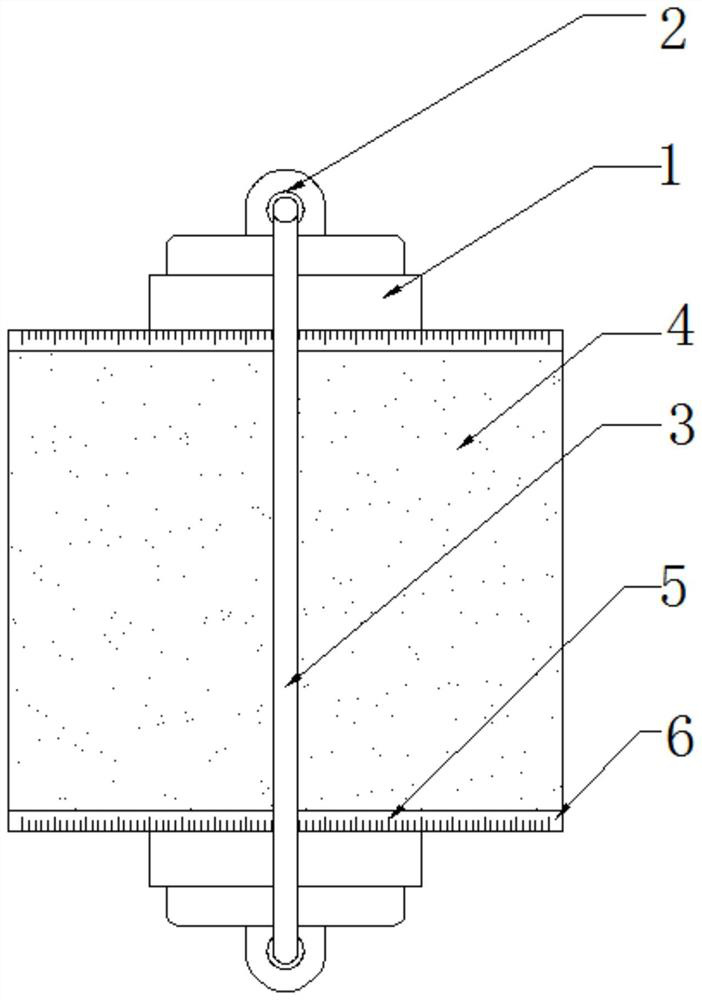

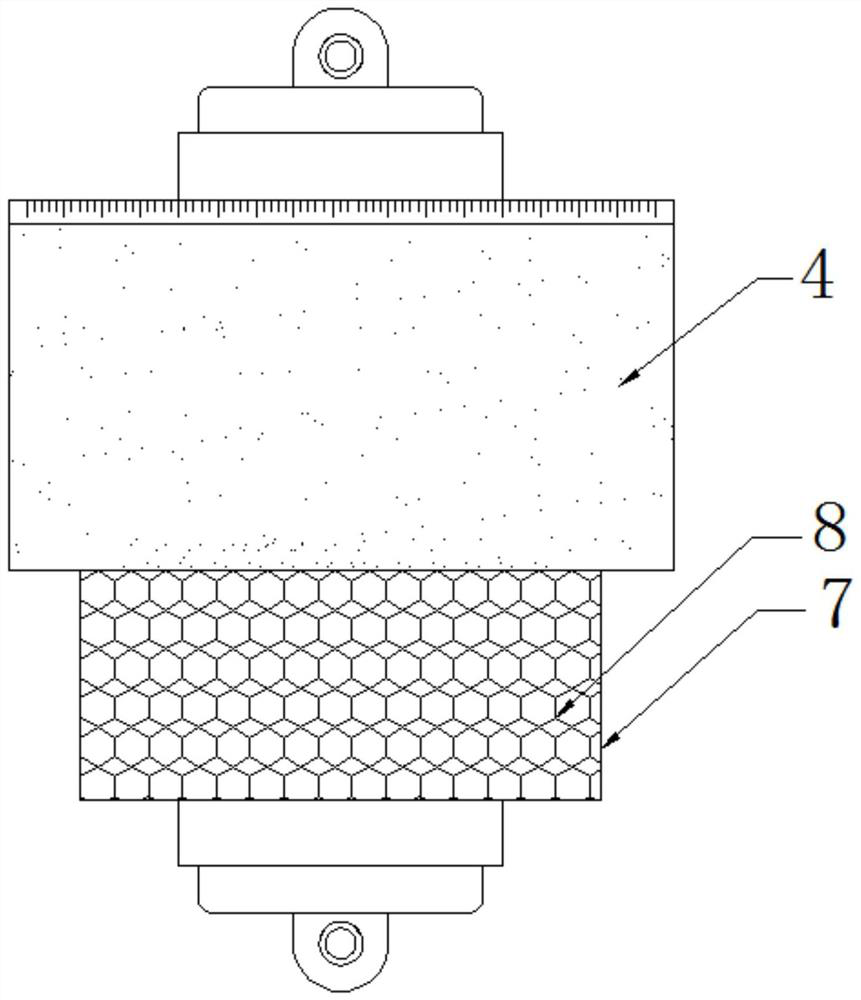

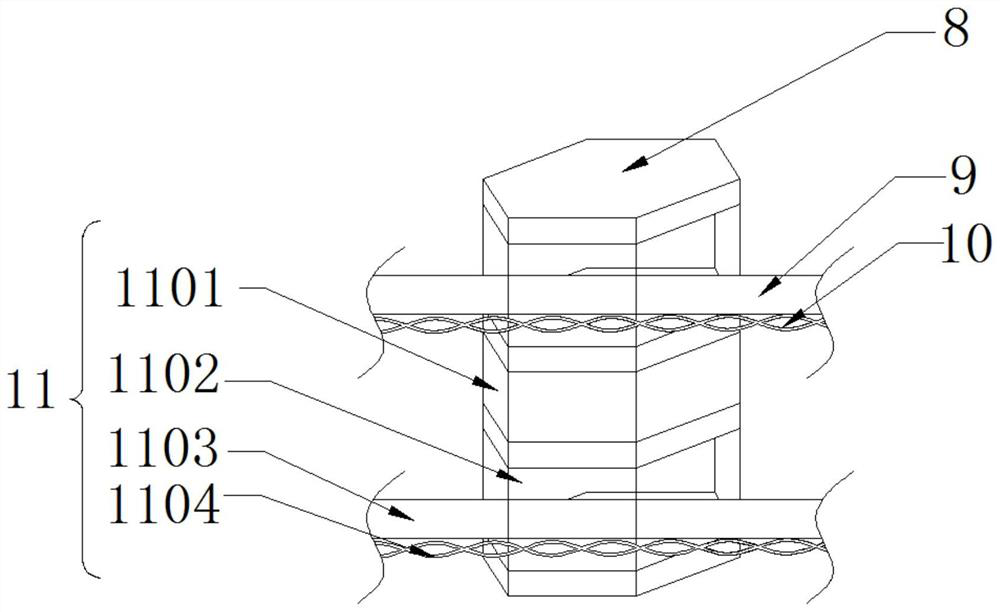

[0027] see Figure 1 to Figure 5 , the present invention provides a technical solution: an antistatic explosion-proof thermal insulation material for deep-sea platforms, including a roller 1, a limiting groove 2, an auxiliary vertical plate 3, a protective film 4, an auxiliary mark 5, a casing 6, a fiber felt 7, Built-in grid felt 8, graphene 9, alumina continuous fiber 10, connecting component 11, transfer layer 1101, bottom grid felt 1102, built-in graphene 1103, built-in alumina continuous fiber 1104, silica gel layer 12, oil felt 13, roll The upper and lower ends of the exterior of the column 1 are provided with limiting grooves 2, and the inside of the limiting groove 2 is equipped with an auxiliary vertical plate 3, and the outer part of the rear end of the auxiliary vertical plate 3 is provided with a protective film 4, and the upper and lower sides of the outer surface of the protective film 4 Both ends are equipped with a cover film 6, the thickness of the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com