Mounting and positioning method in deep repair process of guide plate

A technology for installing positioning and deflectors, which is applied in aircraft maintenance, aircraft assembly, etc., can solve problems such as failure to install and use, interference, and technical status differences, and achieve the effect of reducing the difficulty of assembly work, reducing defects, and reducing debugging and installation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

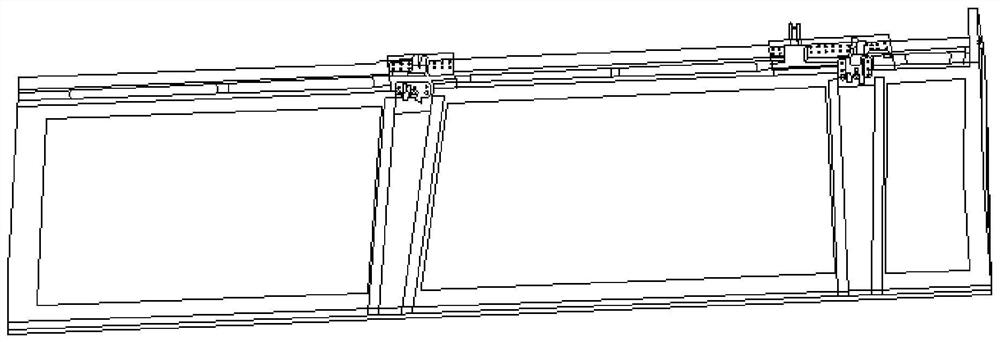

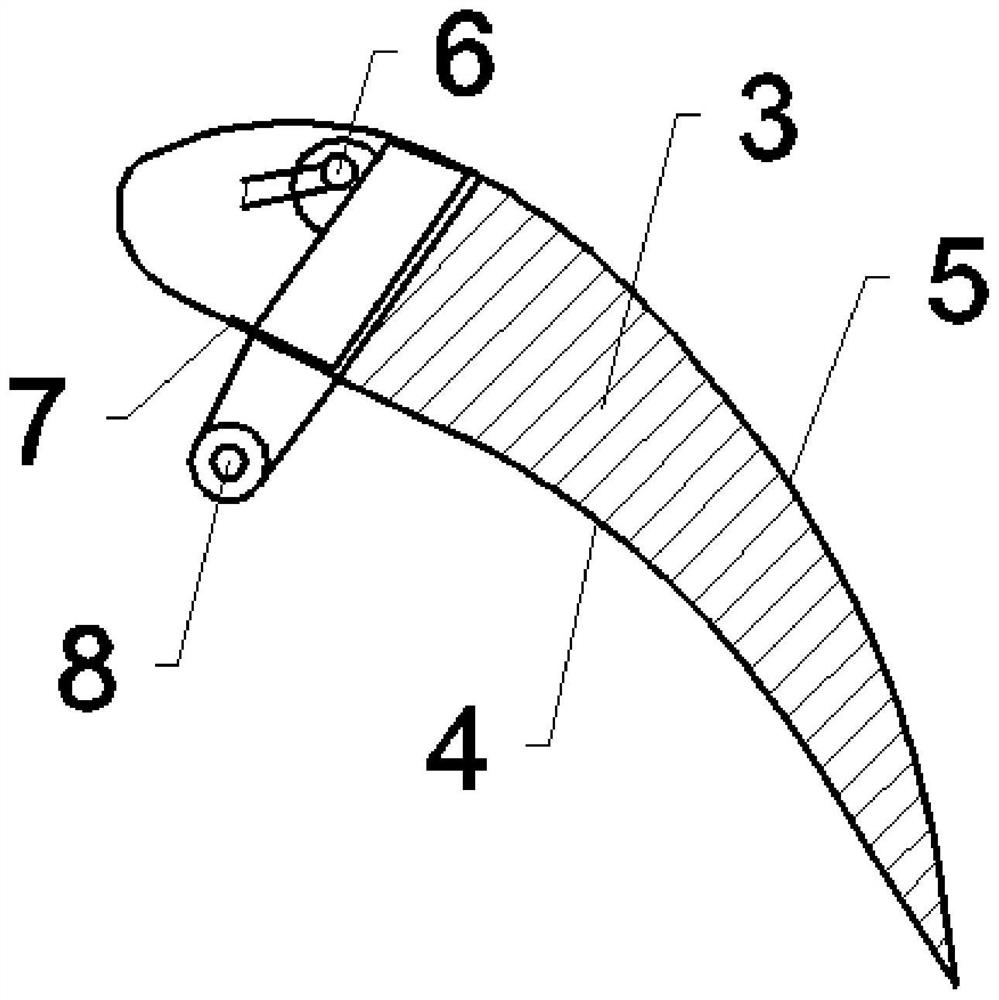

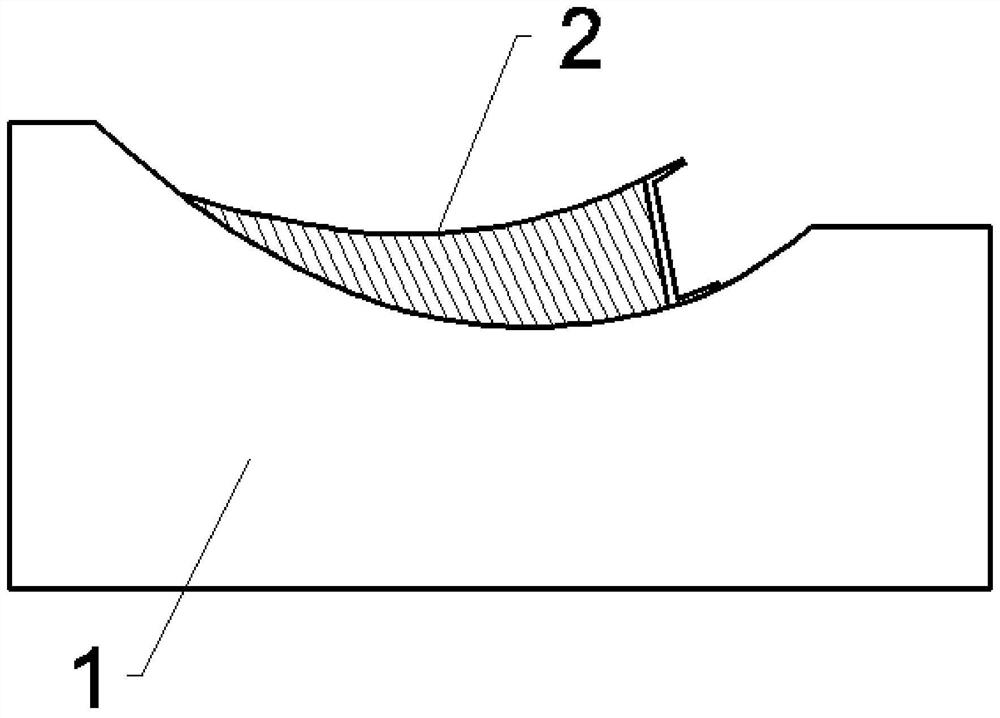

[0032] Such as figure 1 , figure 2 , image 3 As shown in the accompanying drawings, the number 1 is the deflector bonding mold, 2 is the honeycomb unit body, 3 is the honeycomb core, 4 is the lower skin, 5 is the upper skin, 6 is the inner joint, 7 is the girder, and 8 is the Outer connector.

[0033] A method for installing and positioning a deflector in the process of deep repairing, comprising the following method steps in succession:

[0034] a) Before the deflector of the original machine is disassembled, use a 3D scanner to sample and scan the installation state on the machine. Specifically, after the aircraft enters the factory, when the deflector is not removed from the aircraft, the flaps are lowered,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com