Intelligent warehouse

A kind of warehouse and intelligent technology, applied in the field of intelligent warehouse, can solve the problems of slow inbound and outbound, insufficient intelligence, etc., and achieve the effect of improving the speed of inbound and outbound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

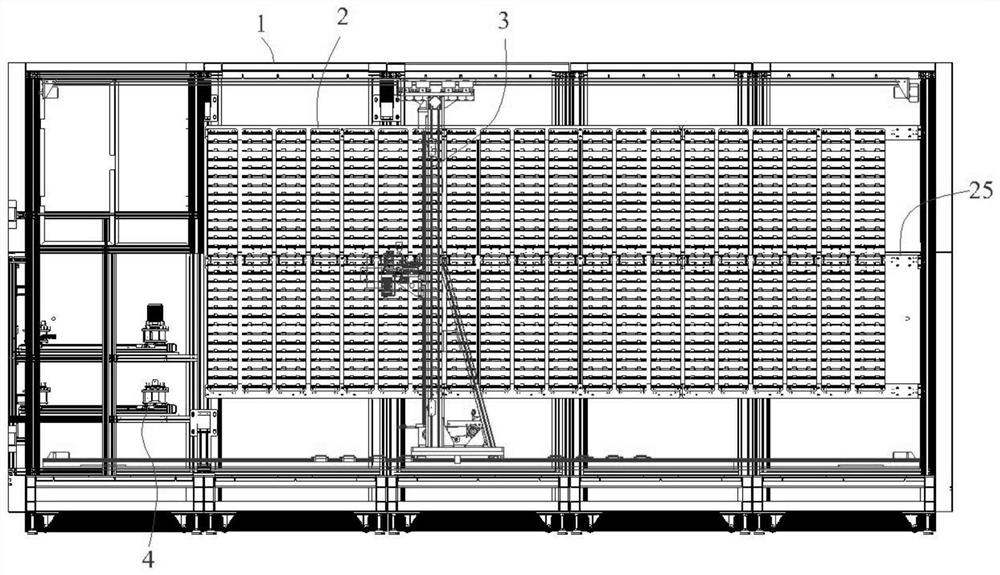

[0062] The invention provides an intelligent warehouse control system, which includes a general control device, a central control device, an intelligent warehouse, and a mobile robot.

[0063]The master control device is used for external interaction and internal control. For the master control device, specifically, it can be a computer, a host, etc. When interacting with the outside world, the master control device receives the task requirements input by the user, generates a transportation task, and sends it to the central The control device sends out transportation tasks. For example, the user needs to store 4 different types of living cells in the warehouse. The user inputs the transportation demand through the master control device, and the master control device generates a transportation task for the 4 different types of living cells. The task controls other devices of the intelligent warehouse control system.

[0064] The central control equipment communicates with the...

Embodiment 2

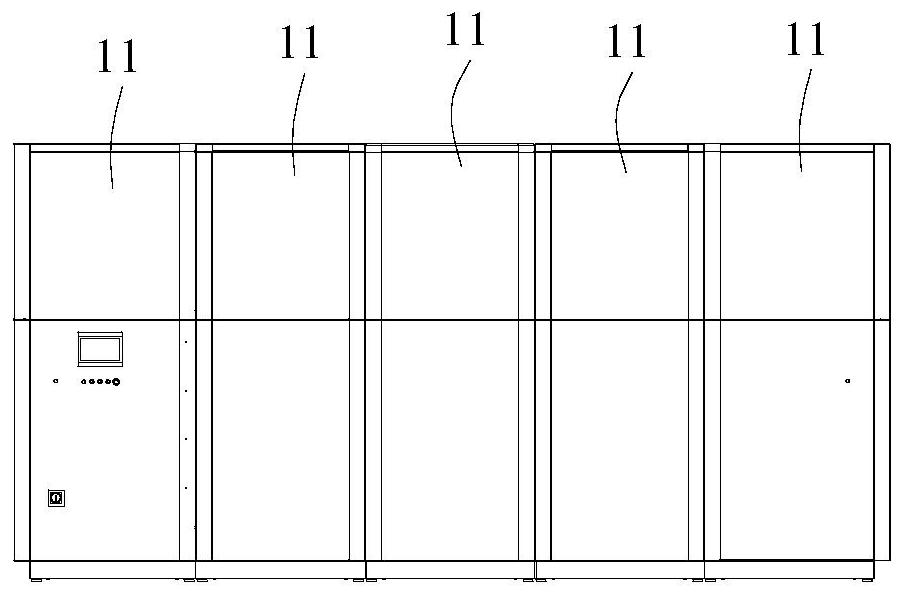

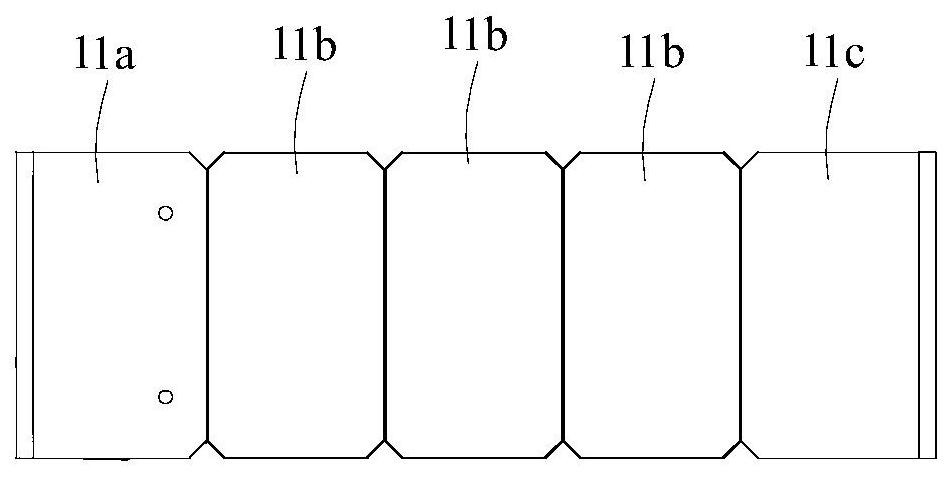

[0093] Such as Figures 2 to 7 As shown, compared with Embodiment 1, the difference is that the warehouse body 1 includes several sequentially connected splicing warehouses 11. Among them, the unit warehouse located at the head end is the control warehouse 11a, and the control warehouse 11a is provided with a material port 113 and a control device for controlling the material entering and exiting from the material port 113 . At least one of the splicing bins 11 is a storage bin 11b for storing materials. The control bin 11a located at the head end is provided with a material port 113 for storage and egress. At the same time, the control device controls the storage of materials, thereby storing the materials in the storage bin 11b. The control device controls the output of the materials to facilitate access to materials. In this embodiment, based on the function of the aforementioned material storage, several splicing bins 11 are set, and the splicing bins 11 are used as a uni...

Embodiment 3

[0109] Such as Figure 8 to Figure 10 As shown, the difference compared with Embodiment 1 and Embodiment 2 is that the storage rack 2 includes at least one storage unit, and the storage unit includes at least two horizontal mounting rods 25 and material carrying components arranged at intervals up and down, and the horizontal mounting rods 25 are spaced up and down. Setting, the material carrying assembly is arranged between two horizontal installation rods 25, the upper end of the material carrying assembly is connected to the upper horizontal installation rod 25, and the lower end of the material carrying assembly is connected to the lower horizontal installation rod 25. Specifically, the upper end of the mounting plate 21 is connected to the upper horizontal mounting rod 25 , and the lower end of the mounting plate 21 is connected to the lower horizontal mounting rod 25 . In order to increase the storage capacity, multiple material carrying assemblies can be arranged side b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com