A kind of medium-deep hole stope bottom structure and recovery method with low mining and cutting ratio

A technology of bottom structure and recovery method, applied in ground mining, earthwork drilling, underground mining, etc., can solve the problem of low recovery rate of pillar ore, and achieve the effect of reducing the amount of mining and cutting engineering, easy recovery, and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

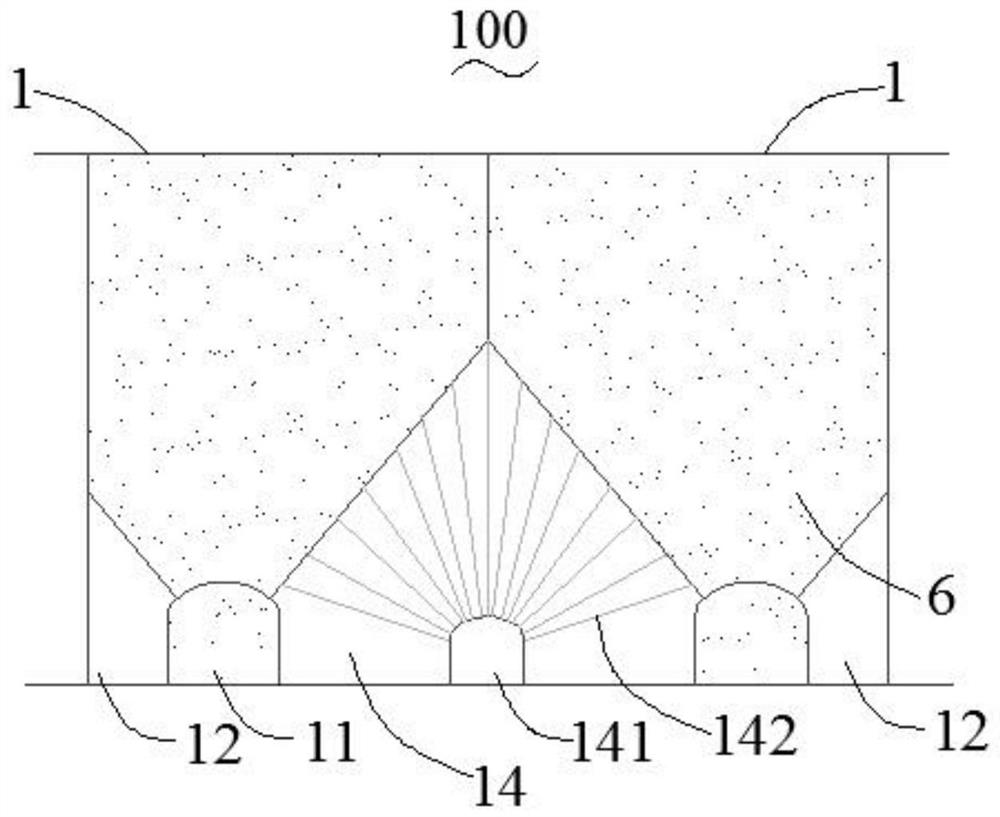

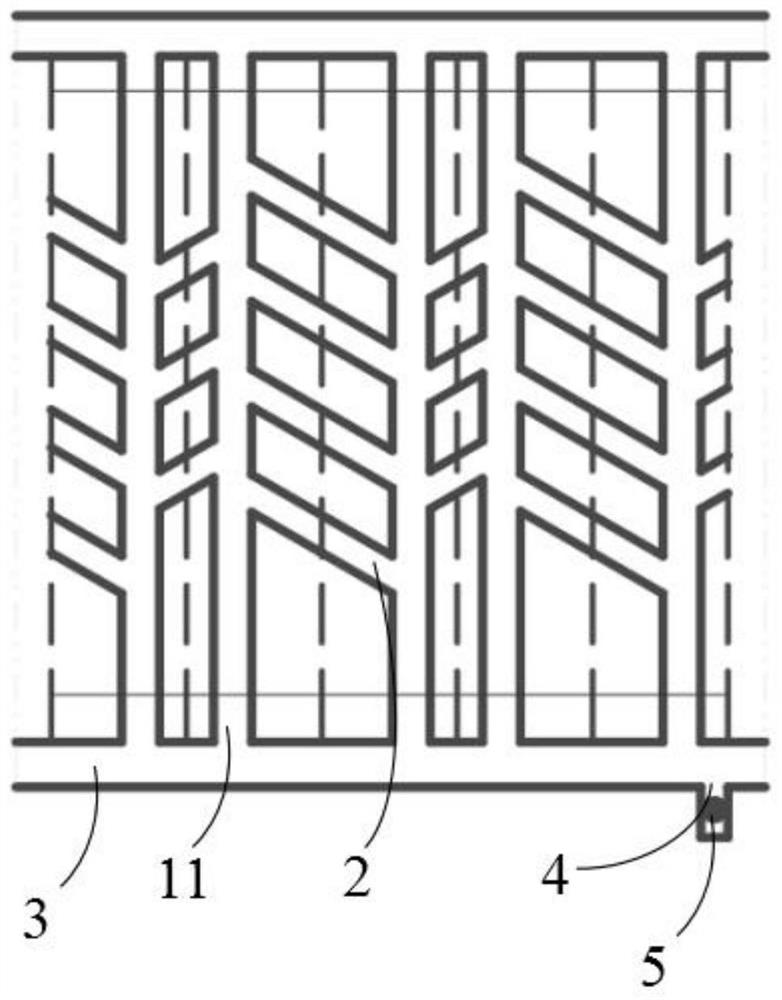

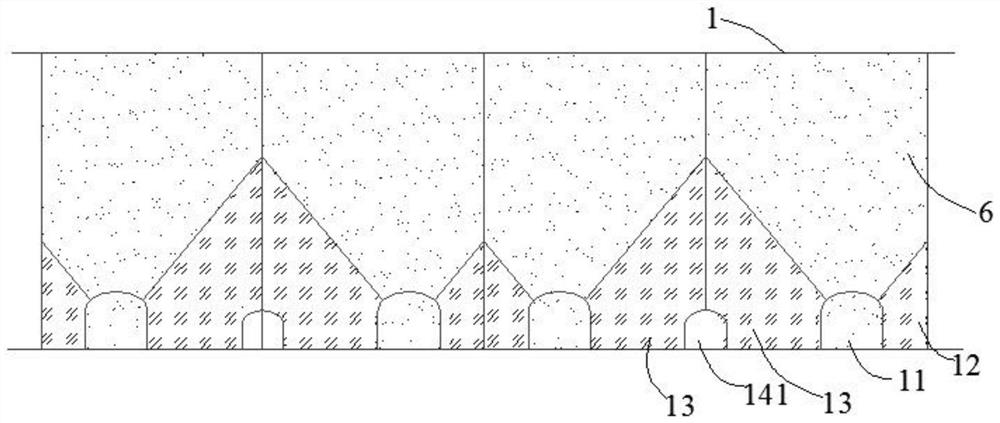

[0044] see Figure 1 to Figure 3 As shown in the figure, a middle-deep hole stope bottom structure with a low cut-to-cut ratio of the present invention includes several adjacent unit stopes 100, and each unit stope 100 includes two mirror images each with a width of 15m. Symmetrical adjacent segmented stopes 1, each segmented stope 1 is provided with rock drilling tunnels 11 distributed in mirror symmetry, and the distance between the central axes of the two rock drilling tunnels 11 is greater than that of a single segmented stope 1. width, forming a large pillar 13. Two large pillars 13 of two adjacent sub-section stopes 1 are combined to form a large triangular pillar 14 with a width of 15.6m and a height of 13m, which is easy to recover; Wherein, the horizontal angles of the free surfaces of the small ore pillars 12 and the large ore pillars 13 in the sectional stope 1 are both 45°. In addition, the unit stope 100 is also provided with a piercing and mining roadway 2 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com