Braking system and control method of hydraulic retarder

A technology of hydraulic retarder and braking system, applied in the direction of brake type, hydraulic resistance brake, brake actuator, etc., can solve the problem of high cost, achieve the effect of reducing control cost and meeting braking requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

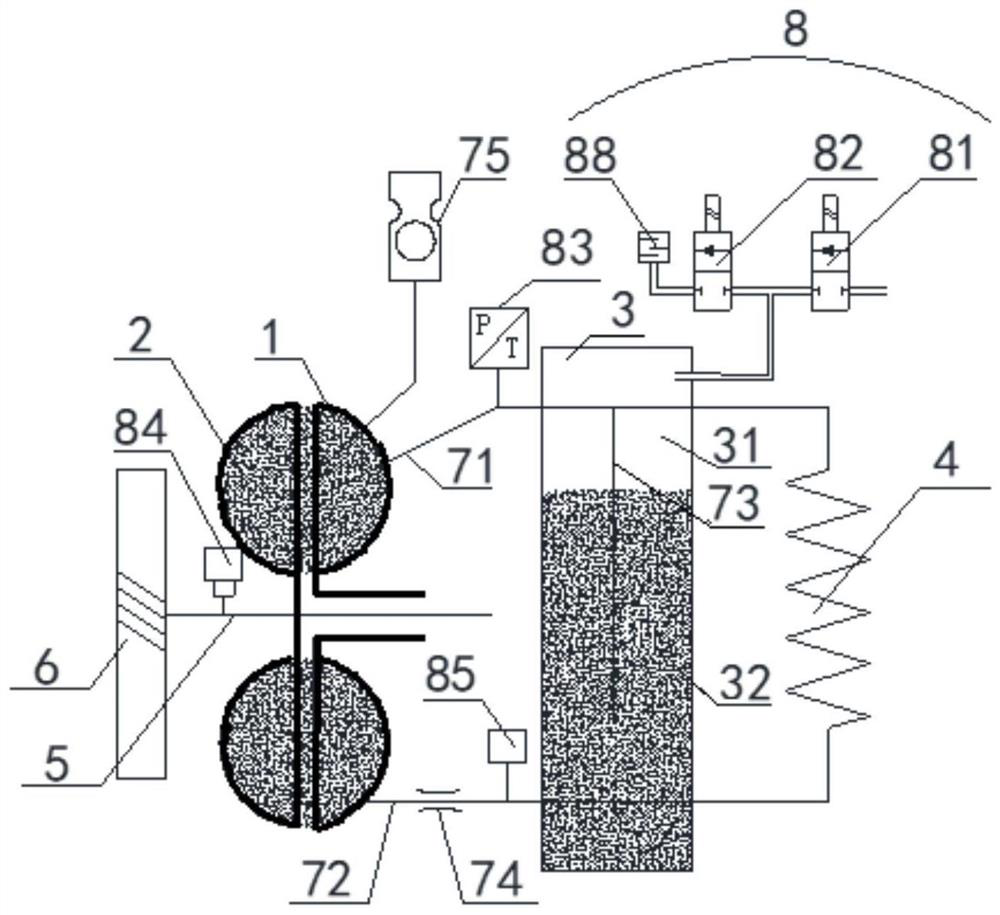

[0063] The present embodiment provides a brake system, such as figure 1 Shown, including hydraulic retarder and control apparatus 8, the control apparatus 8 comprises: a first intake valve 81, a first exhaust valve 82, pressure sensor 83 and a controller;

[0064] First intake valve 81 and the first exhaust valve 82 is at least one of the switching valve, the first intake valve 81, a first end for fluid communication with the high pressure gas tank of the vehicle, the second end of the hydraulic buffer the gear unit 3 communicates air reservoir chamber 31, a first end of the first exhaust valve 82 communicates with the reservoir 31 of the air chamber 3, a second end in communication with the atmosphere; further, the first exhaust valve 82 the second end 88 may be in communication with the atmosphere through the filter;

[0065] A pressure sensor 83 and the reservoir tank 31 is connected to the air chamber 3, for detecting the current pressure in the air chamber 31;

[0066] Input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com