Device for detecting rotor magnetic steel of permanent magnet motor by adopting magnetorheological fluid

A technology of permanent magnet motor and magnetorheological fluid, which is applied in the direction of electromechanical devices, material magnetic variables, magnetic circuit rotating parts, etc., and can solve problems that are not suitable for the actual production of motor rotors, complex calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

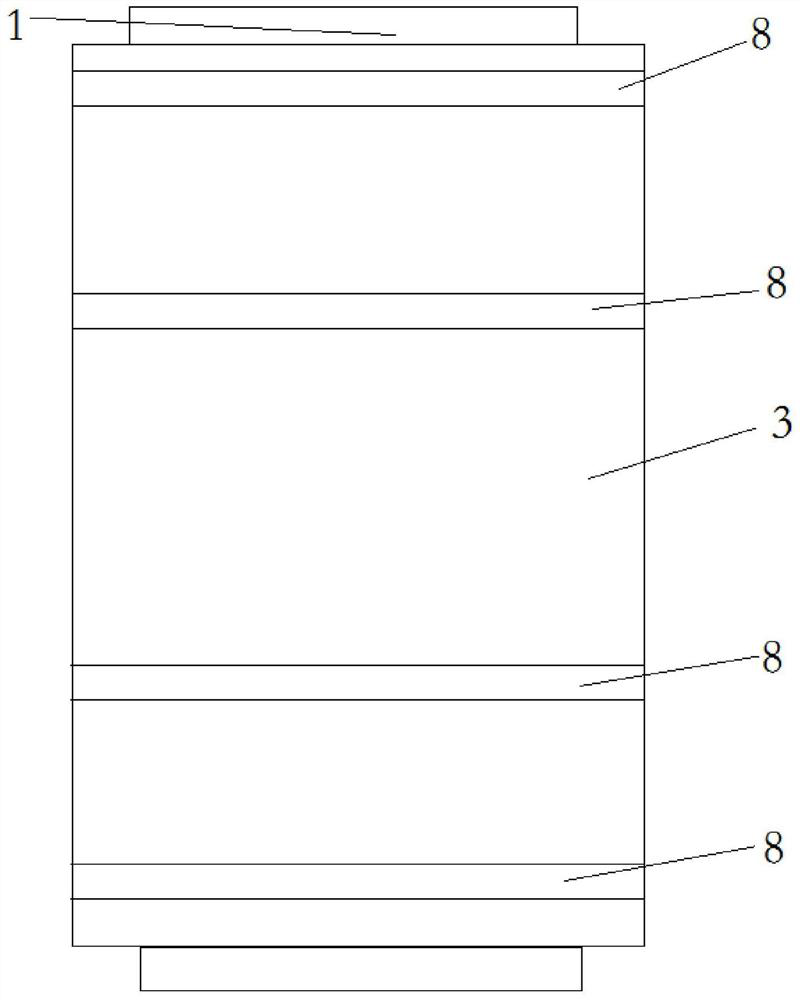

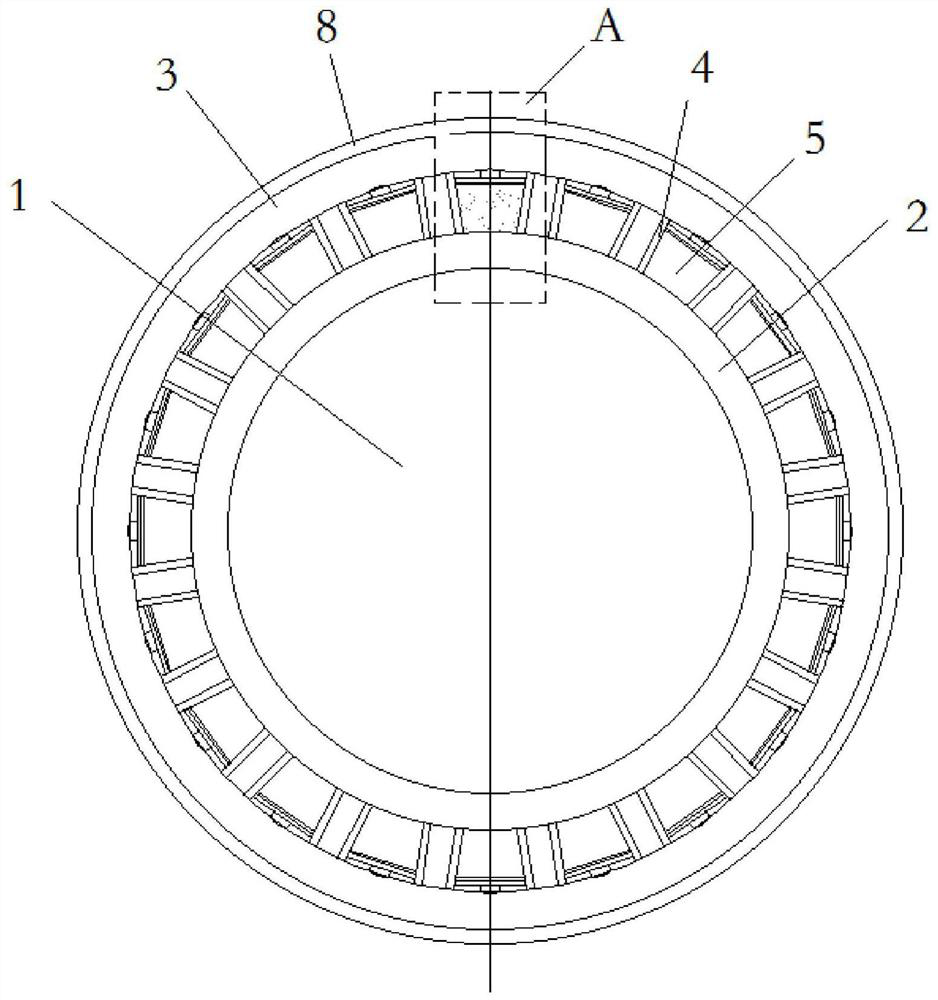

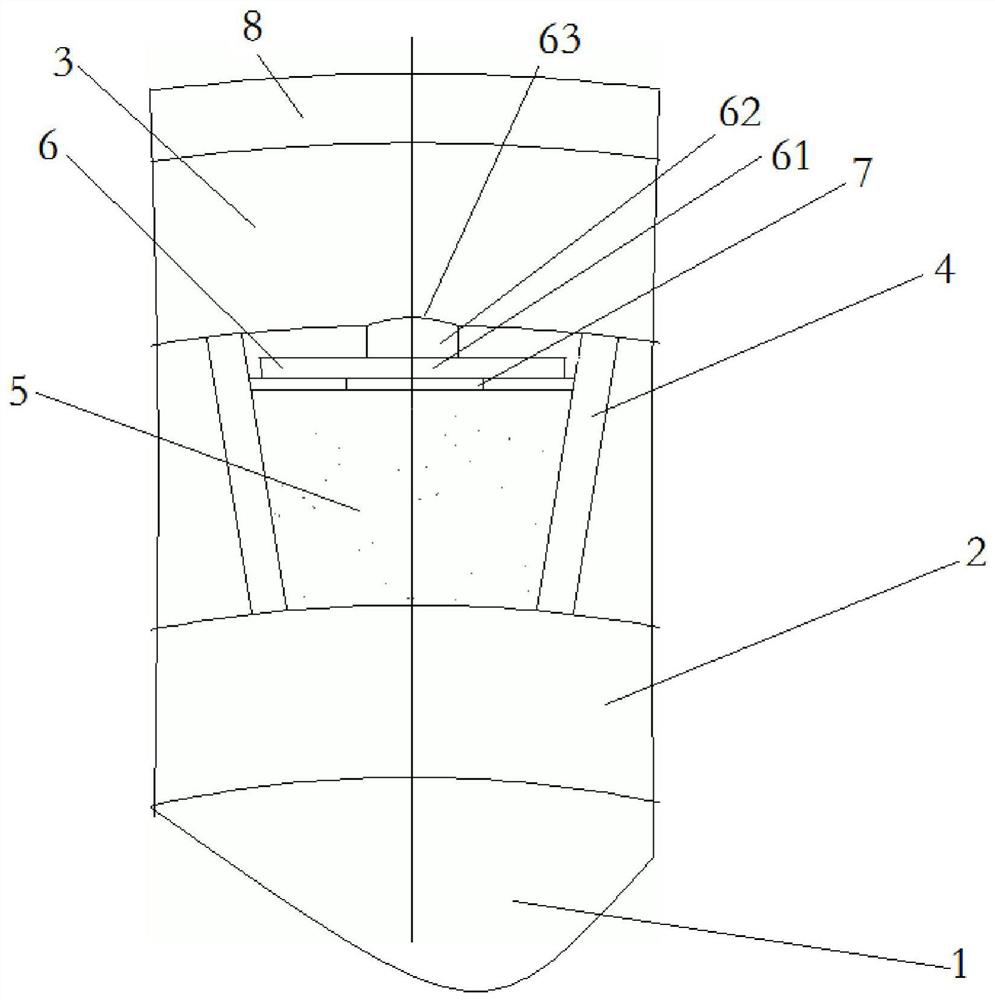

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, the present invention comprises the collar 2 that is sleeved on the outside of permanent magnet motor rotor magnetic steel 1, and the material of described collar can be the material that has elasticity such as nylon; Described collar The inner side of the sleeve is provided with evenly arranged detection units; the detection unit includes a magnetic isolation wall 4, which is arranged along the radial normal of the ring sleeve, that is, the extension line of the magnetic isolation wall passes through the axis P of the ring sleeve; a balloon 5 is arranged in the magnetic isolation wall , the magnetorheological fluid is arranged in the balloon 5; the pressure sensor 7 is arranged on the top of the balloon 5, and the indenter 6 is arranged above the pressure sensor 7, and the upper end of the indenter 6 abuts against the inner side of the airbag 3; the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com