Continuous volume reduction system for solid radioactive waste of underground nuclear power station and use method of continuous volume reduction system

A radioactive waste and radioactive technology, applied in the field of nuclear power, can solve the problems of small capacity reduction effect, inability to operate continuously, and high cost, and achieve the effect of increasing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

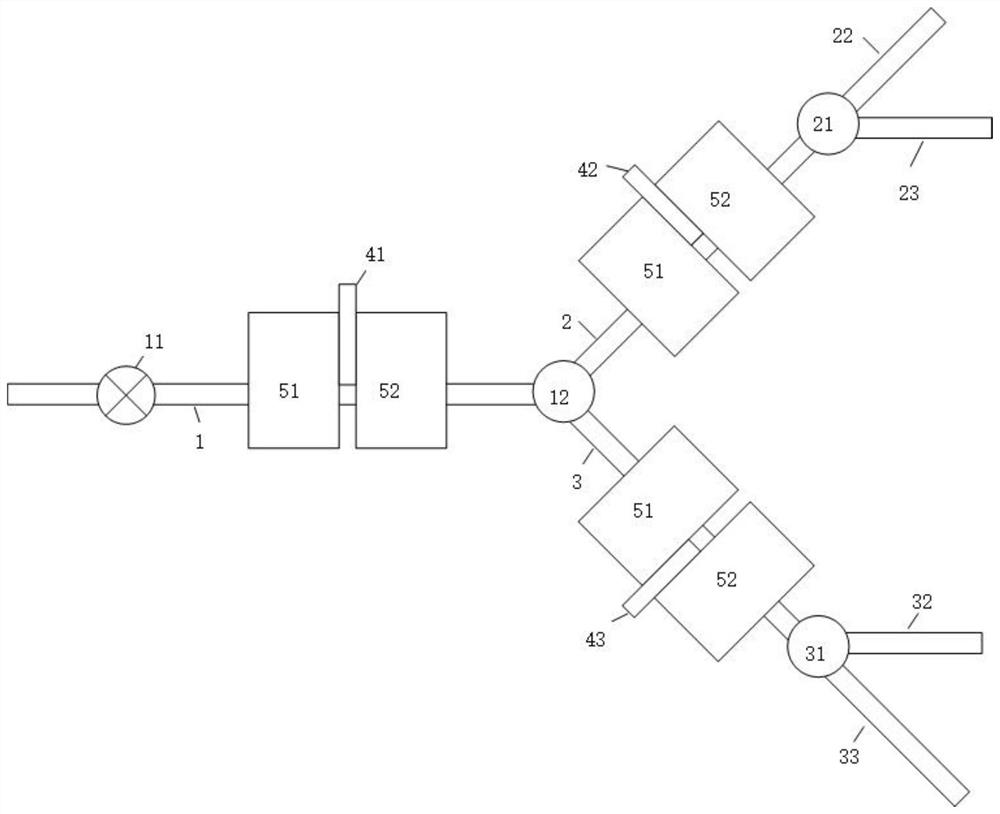

[0032] Referring to the accompanying drawings, it can be seen that the continuous volume reduction system for solid radioactive waste in underground nuclear power plants includes a primary sorting pipe 1, a secondary sorting pipe branch 2 and a secondary sorting pipe branch 3, the primary sorting pipe 1 One end is connected to the power unit 11, and the other end is connected to the primary reversing valve 12;

[0033] One end of the secondary sorting pipe branch 2 is connected to the primary reversing valve 12, and the other end is connected to the secondary one branch reversing valve 21; The branches 23 are all connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com