Improved flexible fireproof cable and wrapping device for production thereof

A fireproof cable, an improved technology, applied in the manufacture of insulated cables, bendable cables, cables/conductors, etc., can solve the problems of poor wrapping quality, complex structure, cable damage, etc., to increase strength and increase fire resistance. , the effect of slowing down the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

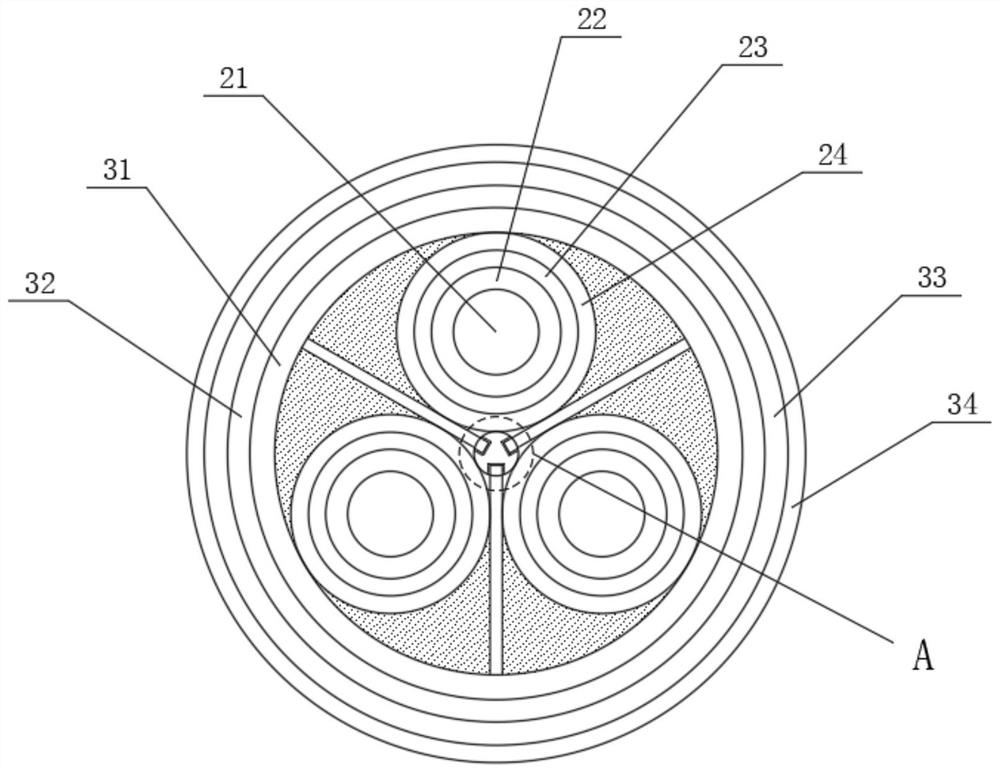

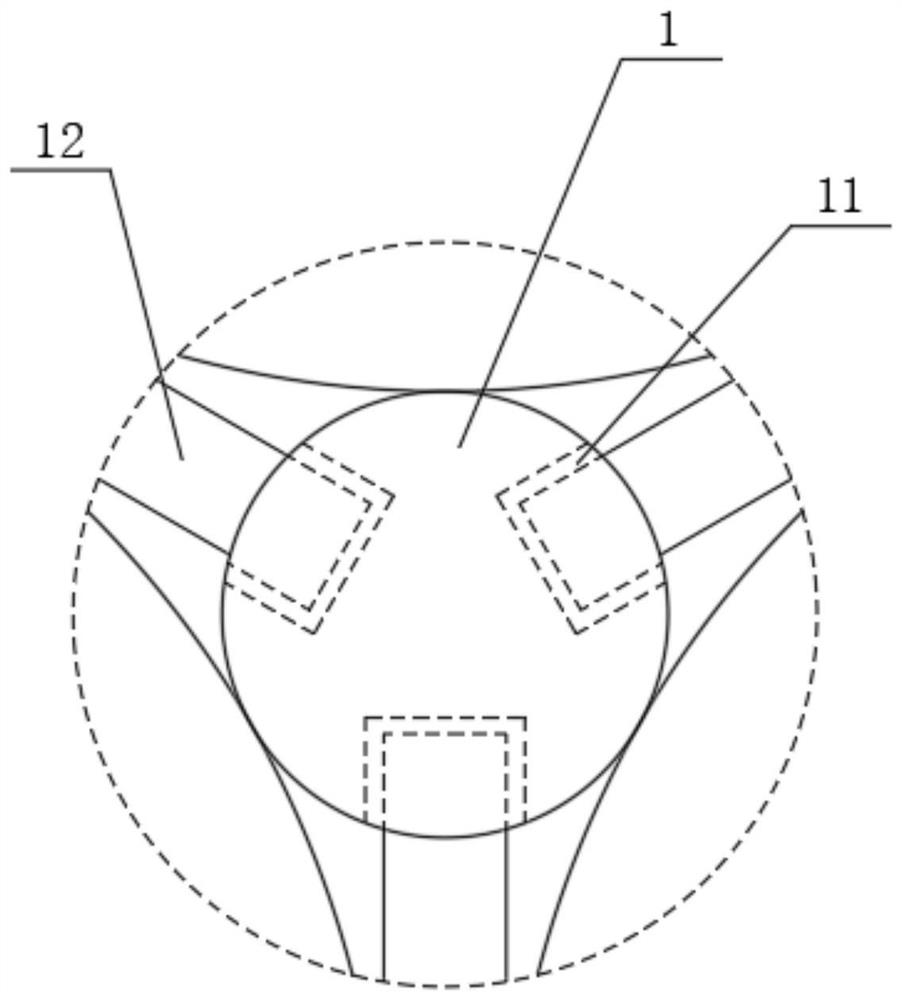

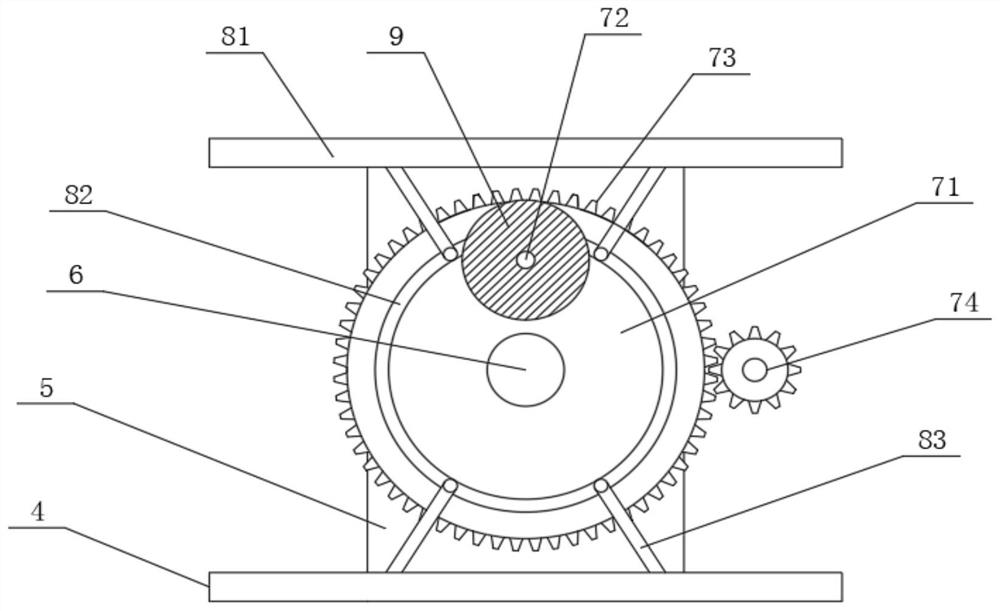

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0039] The invention provides an improved flexible fireproof cable and its wrapping device for production. Its working principle is to increase a layer of mica tape on the conductor and set a layer of foamed ceramic silicon refractory mica layer in the protective component to achieve the improvement. The fireproof characteristics of the cable and the purpose of prolonging the service life of the cable; the fireproof performance of the cable is increased by the filler composed of highly flame-retardant and environmentally friendly materials and ceramics, and the strength of the inner wire body of the cable is also increased, slowing down the wire body in a long time. The degree of corrosion during use.

[0040] The present invention will be described in further detail below in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com