Valve module of thyristor current change valve used for high-voltage DC transmission

A thyristor converter valve, high-voltage direct current technology, applied in output power conversion devices, electrical components, electro-solid devices, etc., can solve the problems of slow replacement, unfavorable valve module installation efficiency, valve module difficulty, etc., to reduce material performance requirements, shortening the length of electrical wiring, the effect of optimizing electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

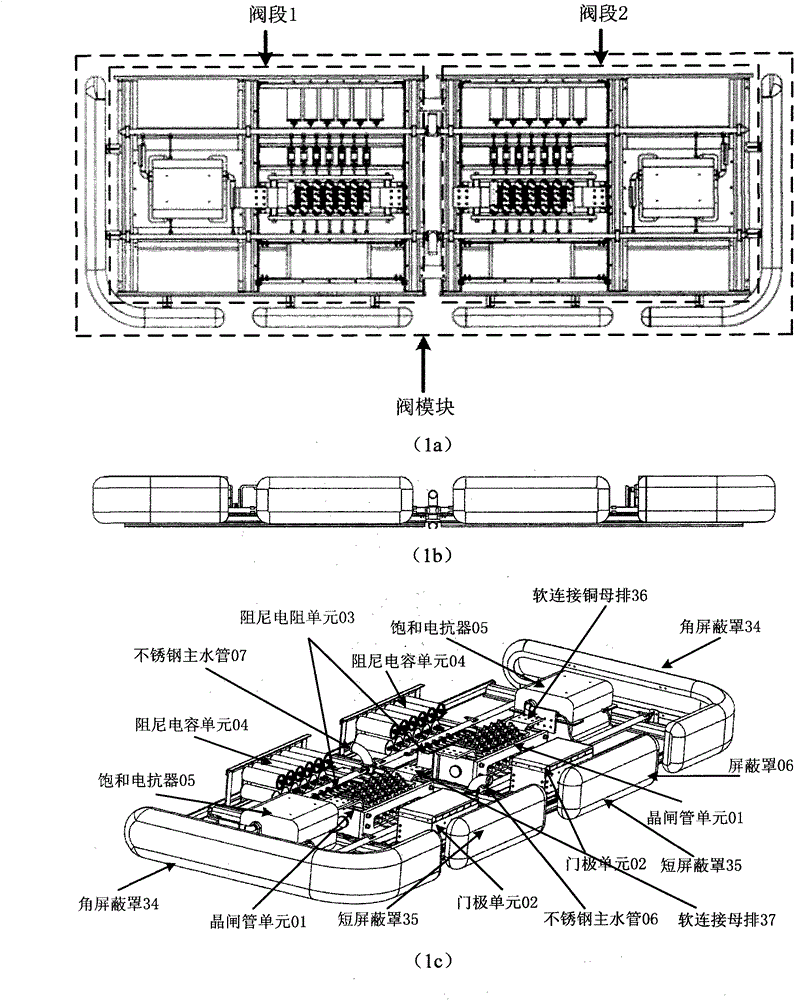

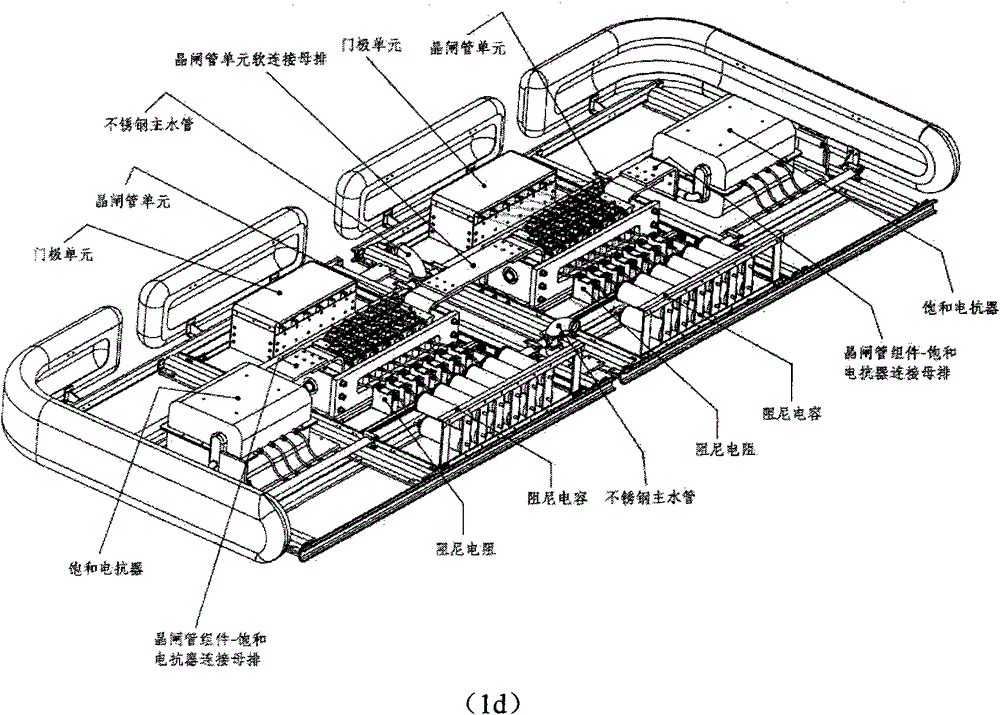

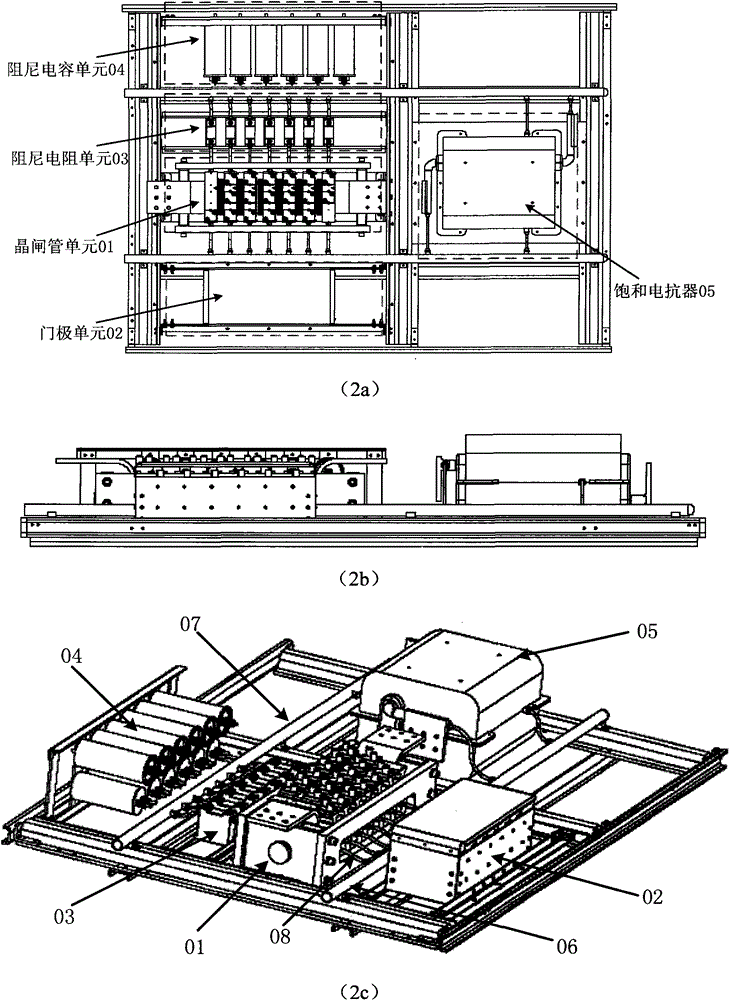

[0034] Such as figure 1 and figure 2As shown, the valve module includes two valve sections: valve section 1 and valve section 2, and each valve section includes a saturable reactor assembly 05 and a thyristor stage assembly 00. The saturable reactor assembly 05 is located on both sides of the valve module, and the thyristor-level assembly 00 is located in the middle of the valve module. There are multiple shields on the three peripheries of the valve module (there is no shield on the side of the damping capacitor), and the structure of the shields is an arc-shaped structure, which is divided into two types: corner shields 34 and short shields 35 . The electrical connection between the saturable reactor 09 and the thyristor unit 01 is realized through the soft connection copper busbar 36, and the electrical connection of the two val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com