Fuel cell hydrogen supply and hydrogen return integrated system

A fuel cell and integrated system technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of easy accumulation of water, freezing and blockage, large space occupation, long transmission distance, etc., to achieve compact structure, The effect of high installation efficiency and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

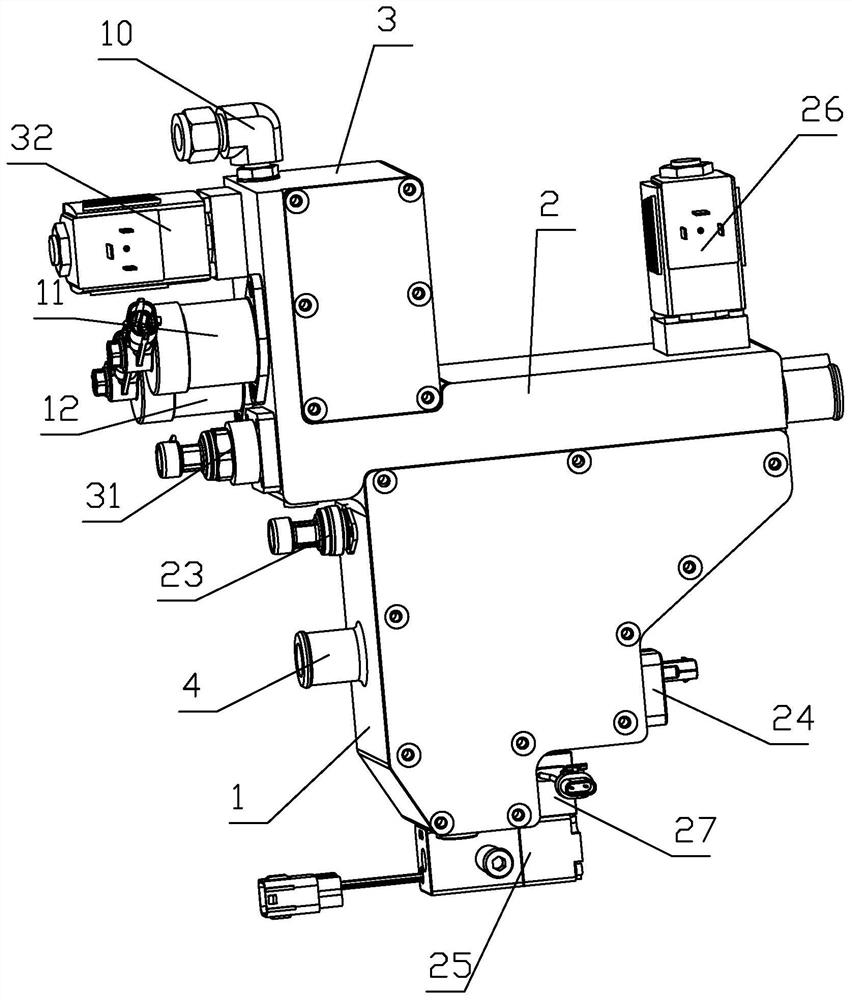

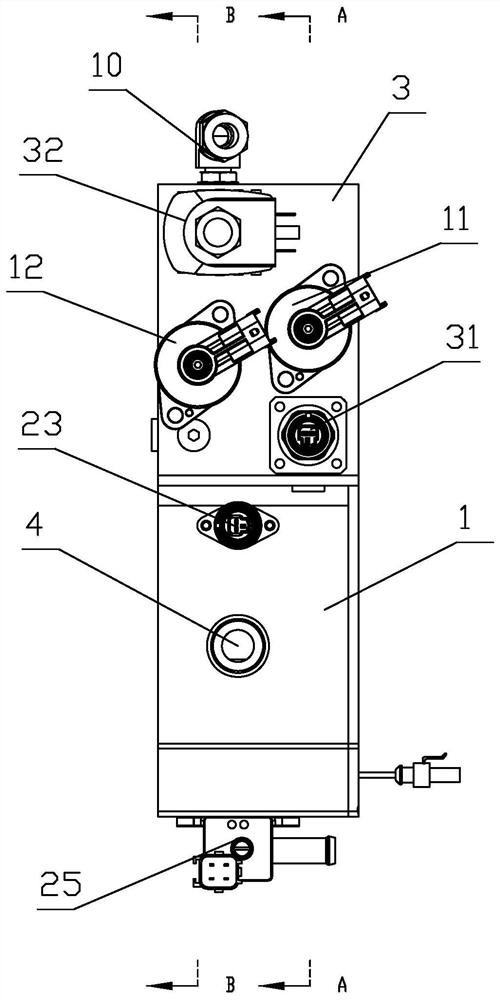

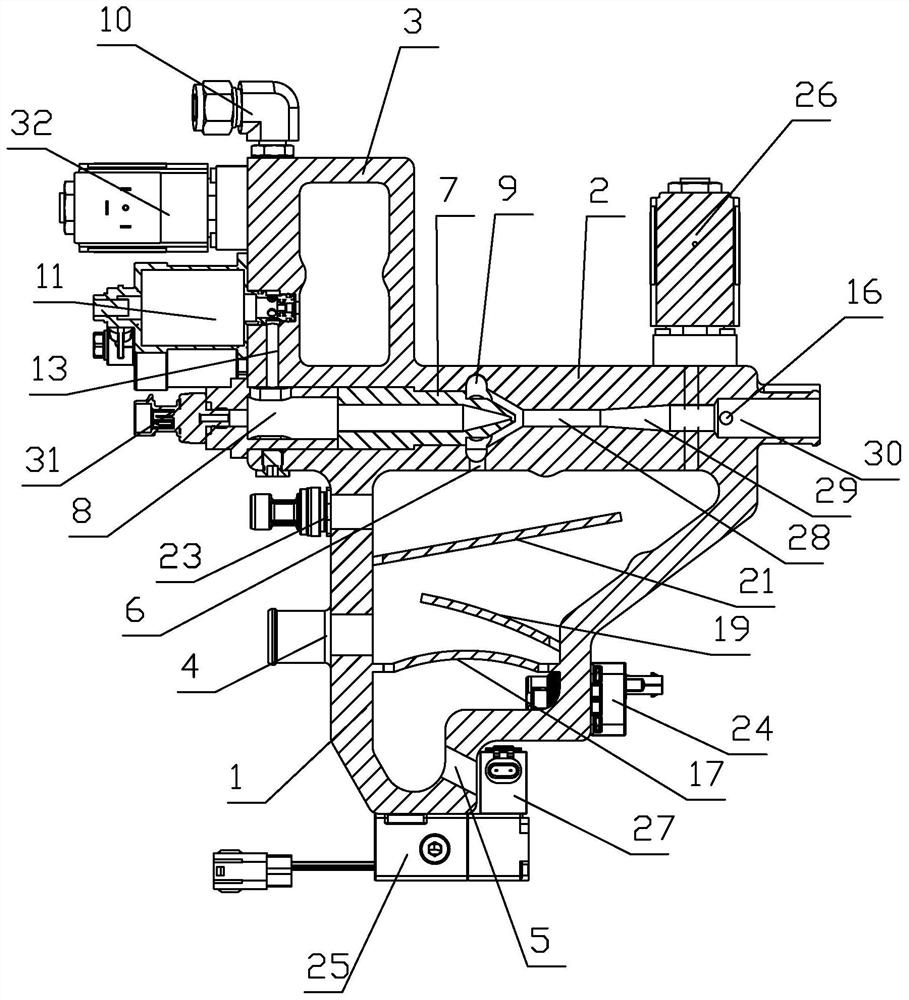

[0034] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0035] Such as Figure 1-5 As shown, a fuel cell hydrogen supply and return hydrogen integrated system, including:

[0036] An integrated housing, which includes a lower gas-water separator housing 1, an upper ejector housing 2 and a buffer chamber housing 3;

[0037]One side of the gas-water separator housing 1 is provided with a hydrogen return inlet 4, the bottom of the gas-water separator housing is provided with a drain outlet 5, and the top of the gas-water separator housing is provided with a hydrogen return outlet 6. A labyrinth structure is installed inside the shell to separate the water in the hydrogen-containing mixed gas;

[0038] A high-pressure nozzle 7 is installed on one side of the ejector housing 2, the front side of the high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com