Constant-temperature and constant-humidity cigar cabinet and control method thereof

A constant temperature and humidity technology for cigar cabinets, applied in tobacco, tobacco processing, food science, etc., can solve problems such as humidity fluctuations in the cabinet, failure to meet cigar storage conditions, and quality differences in cigars, so as to reduce parts and detection accuracy Requirements, stable temperature and humidity control process, and small temperature fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

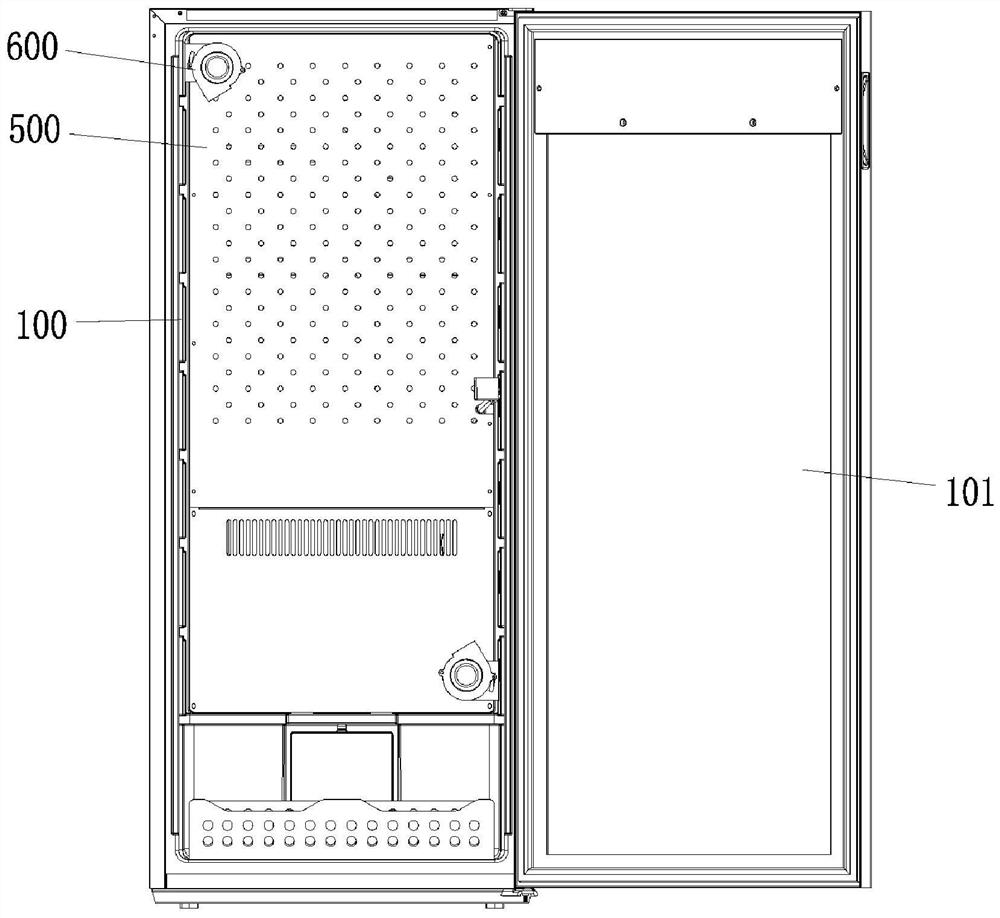

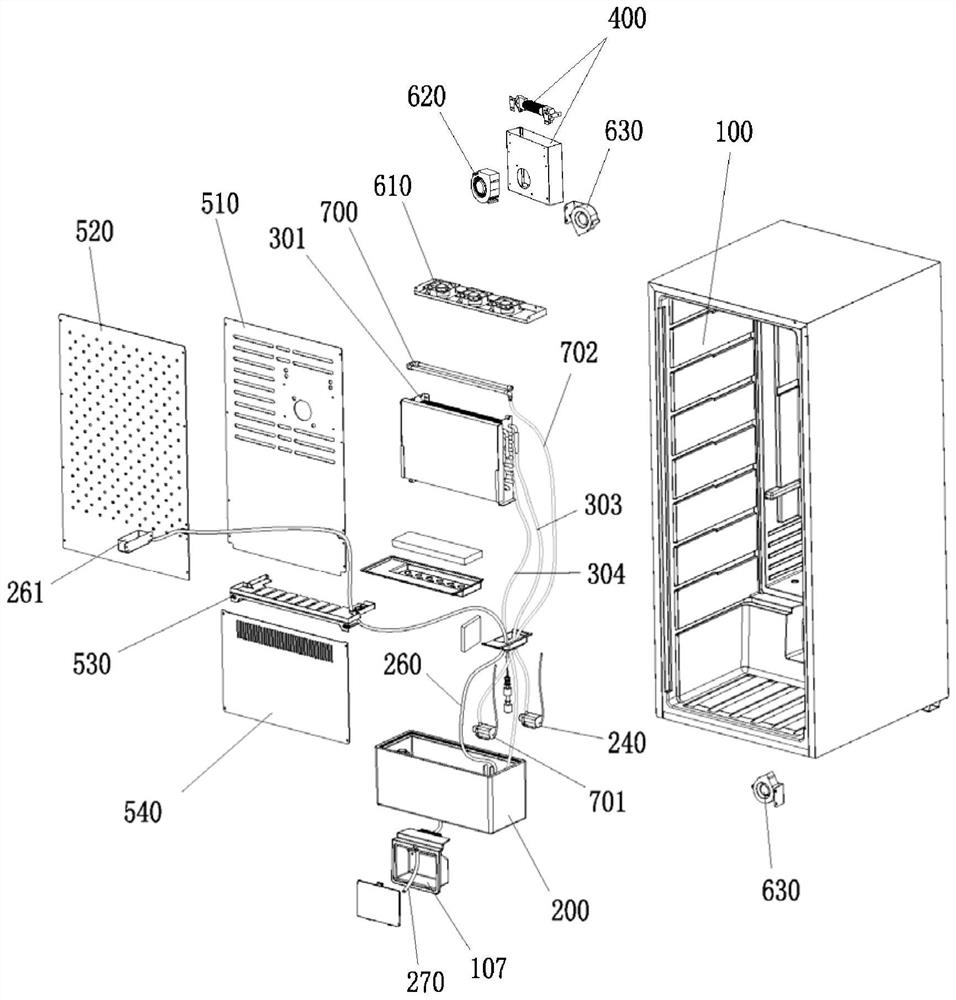

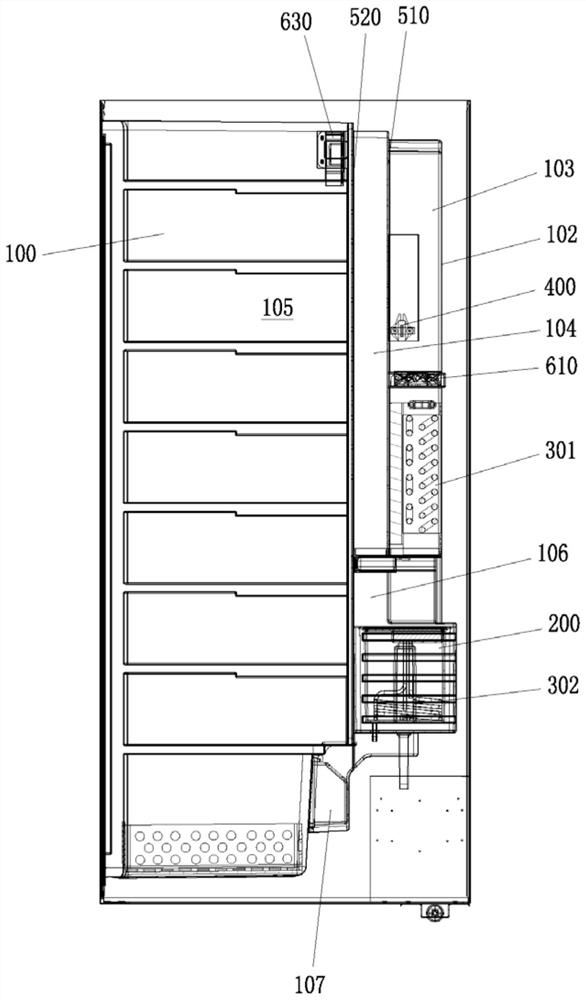

[0061] This embodiment provides a constant temperature and humidity cigar cabinet, such as Figure 1-11 As shown, it includes an inner tank 100 and a temperature control device, a humidifying device and an air guiding device arranged in the inner tank 100;

[0062] The temperature control device includes a water tank 200, a cooling assembly 300 and a heating assembly 400;

[0063] Wherein the refrigeration assembly 300 includes a heat exchanger 301 and a water immersion evaporator 302, the water immersion evaporator 302 is arranged in the water tank 200 and cools the water in the water tank 200 through the compressor assembly, and the heat exchanger 301 communicates with the cold water in the water tank 200 for the refrigeration cycle;

[0064] Wherein the humidifying device is used to extract the water in the water tank 200 and spray it on the surface of the heat exchanger 301 to form a high-humidity environment at the heat exchanger 301;

[0065] The wind guide device incl...

Embodiment 2

[0105] This embodiment provides a control method for a constant temperature and humidity cigar cabinet, which controls the constant temperature and humidity cigar cabinet provided in Embodiment 1, including:

[0106] Step 1. Measure the actual temperature value, actual humidity value and current water temperature value in the water tank in the third area, and calculate the current dew point temperature value and the water temperature value to be set according to the actual temperature value and actual humidity value in the third area;

[0107] Among them, set water temperature value = current dew point temperature value - dew point temperature deviation value;

[0108] The dew point temperature deviation value is determined by the integral algorithm according to the current humidity value and the target humidity value, and the dew point temperature deviation value is increased or decreased by comparing the current humidity value and the target humidity value, and the dew point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com