Cloth bag-type dust collector for industrial dust collection

A bag filter and industrial technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of dust bag damage, dust bag burning, air flow influence, etc., and reduce the phenomenon of sticking bags. the probability of damage, the effect of reducing the probability of damage, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

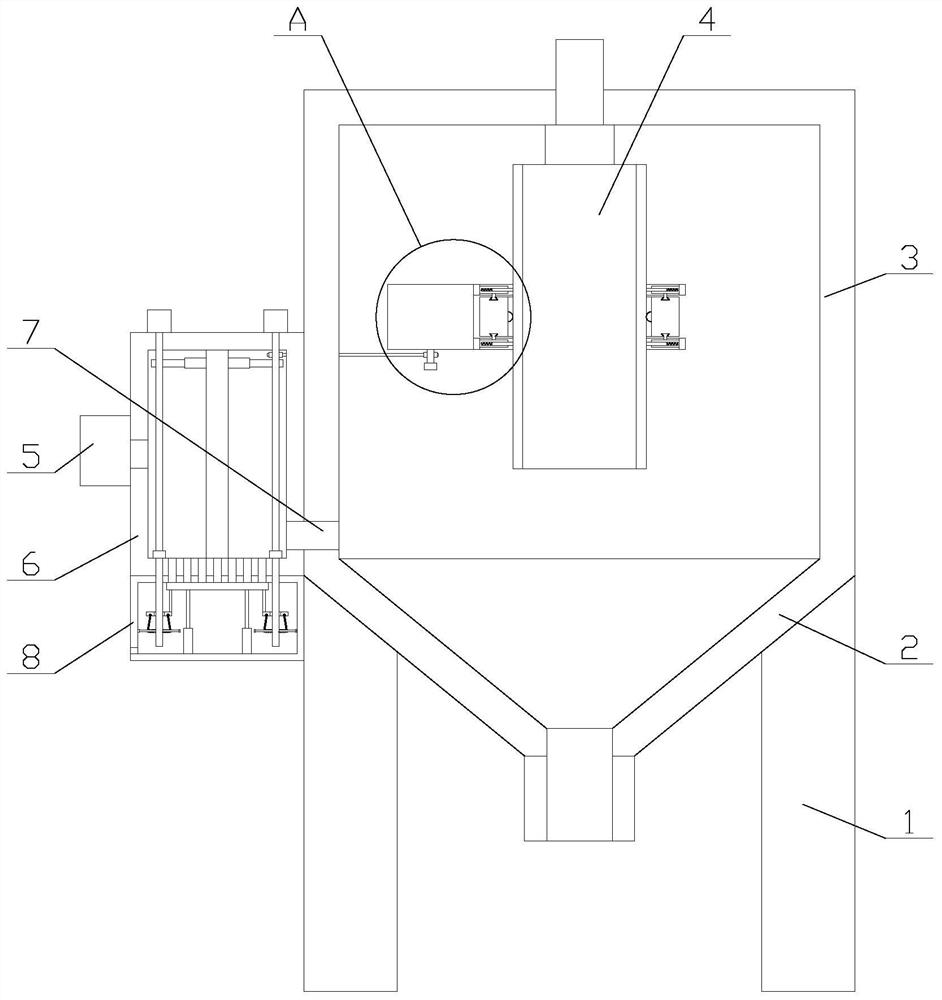

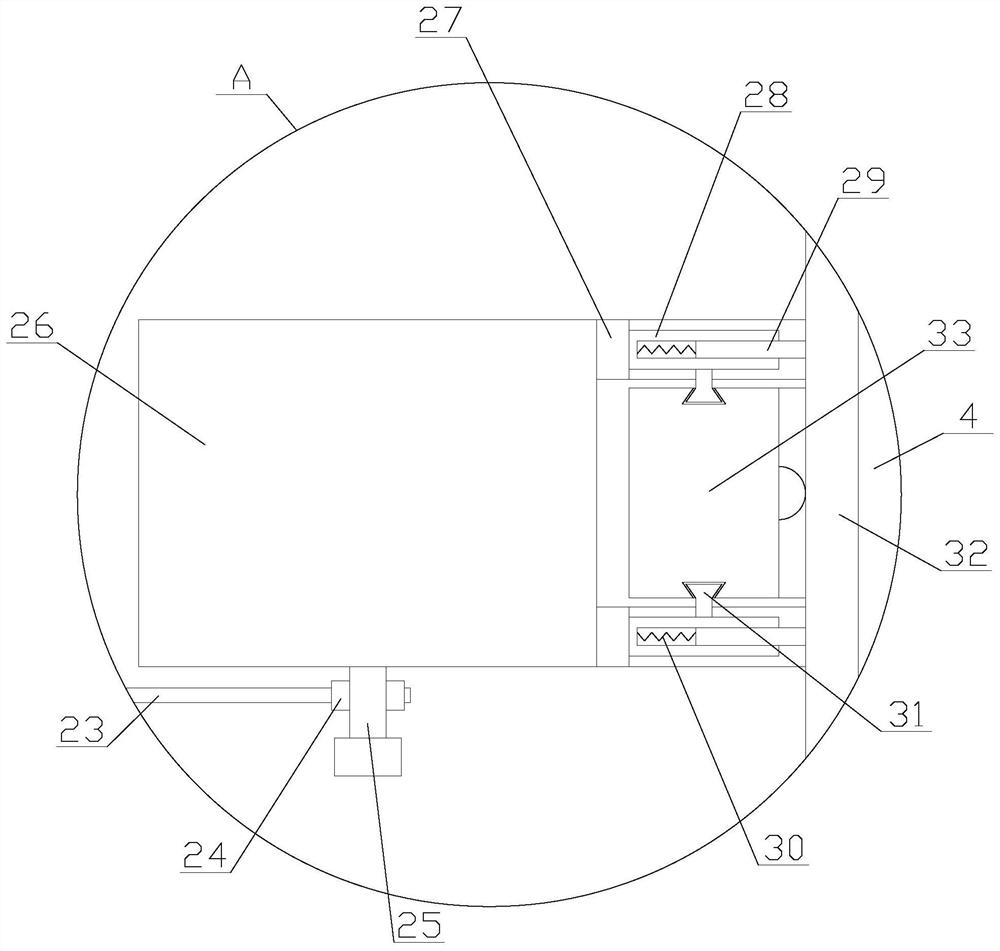

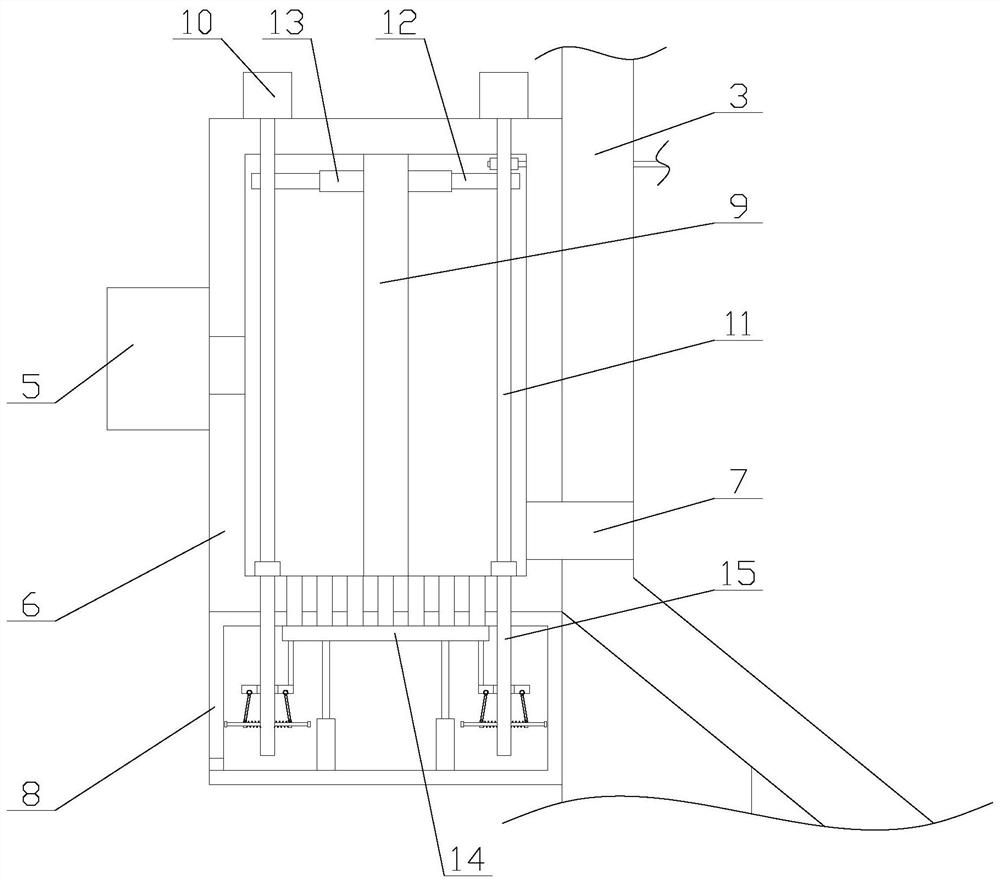

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] Such as figure 1 As shown, a bag filter for industrial vacuuming includes a main body 3, a dust collecting bucket 2, a dust bag 4, a fixed box 6, a dust suction device 5, a connecting pipe 7 and two legs 1, the main body 3 It is arranged above the dust collecting hopper 2, the main body 3 communicates with the dust collecting hopper 2, and the two legs 1 are respectively connected with the two sides below the dust collecting hopper 2, and the dust removal bag 4 is arranged on the top of the main body 3, The fixed box 6 is arranged on one side of the main body 3, the dust suction device 5 is arranged on the side of the fixed box 6 away from the main bod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap