A method for co-processing and recycling of metallurgical solid waste and municipal waste incineration fly ash

A technology of waste incineration fly ash and incineration fly ash, which is applied in solid waste management, sustainable waste treatment, solid waste removal and other directions, can solve the problems of catalyst recovery and expensive catalyst, and achieve the effect of promoting degradation and improving removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

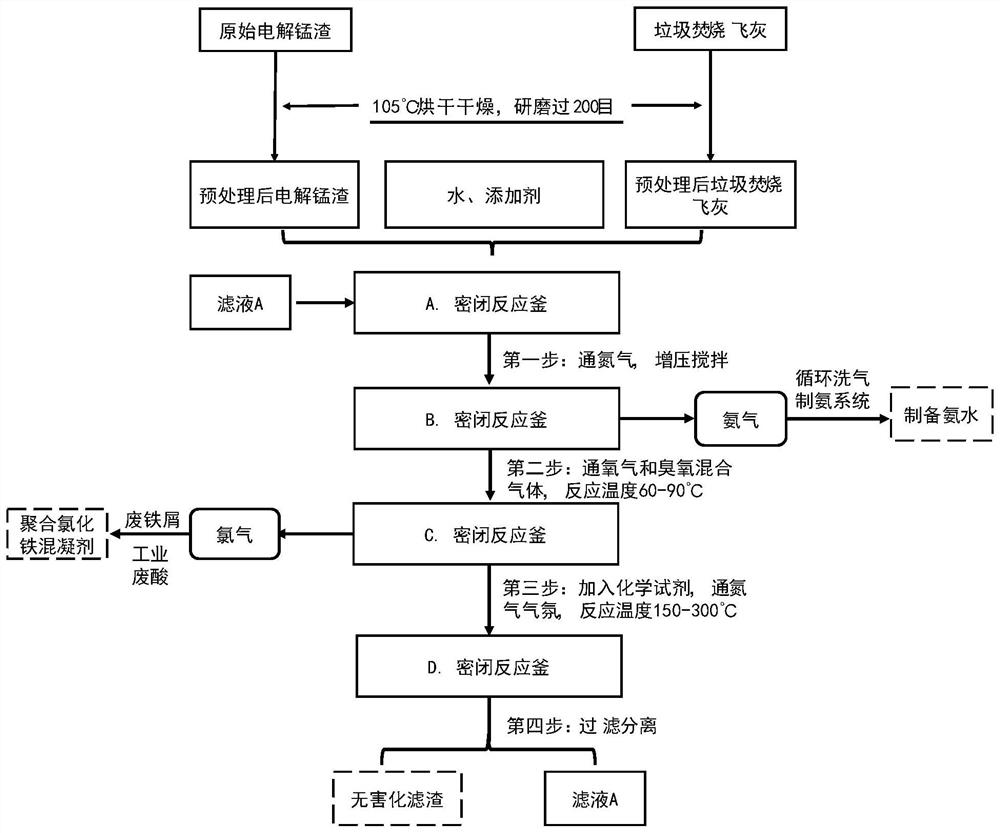

Method used

Image

Examples

Embodiment 1

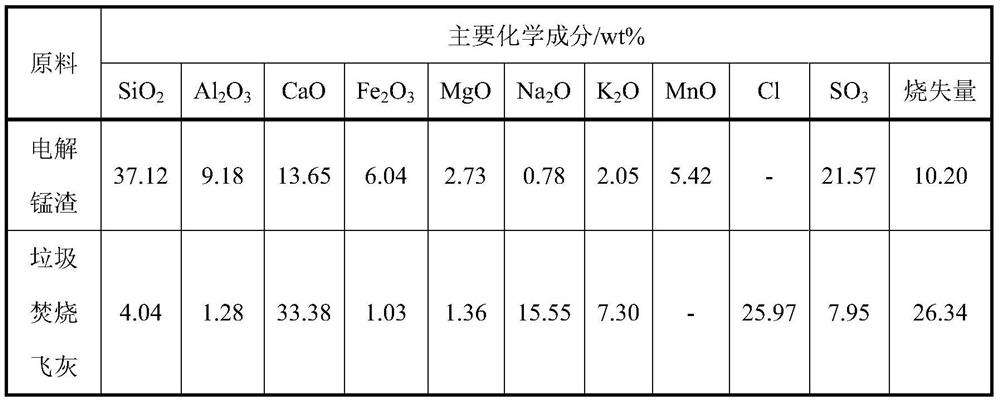

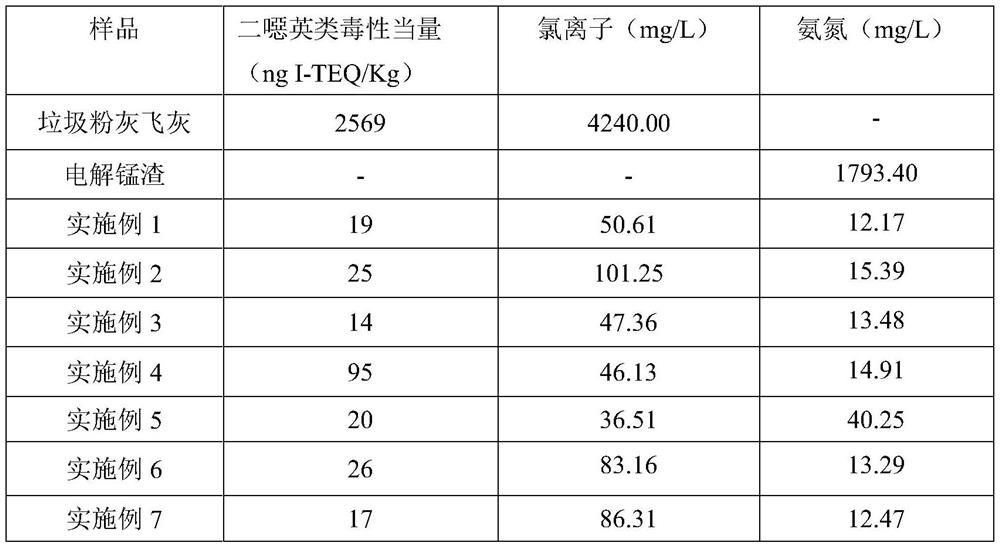

[0058] In this embodiment, the synergistic harmless treatment of electrolytic manganese slag and waste incineration fly ash and its functional material preparation method include the following steps:

[0059] (1) Synergistic removal of ammonia nitrogen in metallurgical solid waste: Mix the electrolytic manganese slag and waste incineration fly ash according to the mass ratio of 70:30 to obtain a mixture; the mixture and water are added into the airtight container according to the solid-liquid mass ratio of 1:10 In the stirred reactor, react at 80°C for 20min, and the stirring rate is 20r / min, and the reaction will generate ammonia gas. During the reaction, 500mL / min N 2 , so that the ammonia gas produced by the reaction is discharged with the airflow and enters the tail gas recovery system to prepare ammonia water.

[0060] (2) Removal of chlorine ions in the solution: After the reaction in step (1), pass the mixed gas of ozone and oxygen (volume ratio 3:2), the gas flow rate ...

Embodiment 2

[0067] This example utilizes electrolytic manganese slag and garbage incineration fly ash synergistically harmless treatment and its functional material preparation method, step (2) through the mixed gas of ozone and oxygen (volume ratio 1:3), other steps and embodiment 1 same.

Embodiment 3

[0069] In this example, the synergistic harmless treatment of electrolytic manganese slag and waste incineration fly ash and the preparation method of functional materials are used. In step (3), the reaction temperature is 200°C and the treatment is continued for 3 hours. The other steps of this example are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com