Automatic leveling device for conveying platform and loading machine

An automatic leveling and conveying platform technology, applied in the direction of conveyor control device, ground device, loading/unloading, etc., to achieve the effect of stable docking, high cargo transmission efficiency, and consistent docking height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

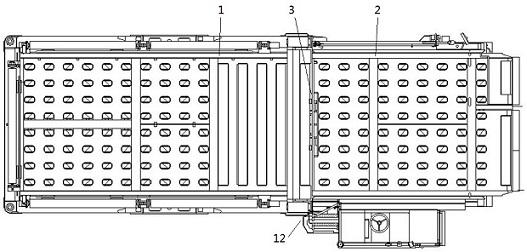

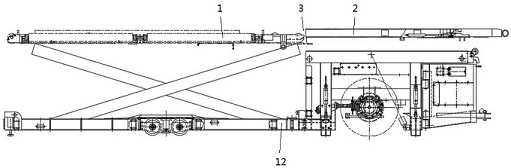

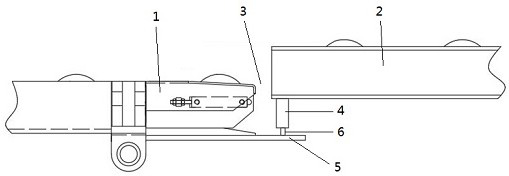

[0018] An automatic leveling device for a transmission platform, comprising a main platform 1 and a bridge platform 2, characterized in that an automatic leveling mechanism 3 is provided between the main platform 1 and the bridge platform 2, and the automatic leveling mechanism 3 includes a stopper Plate 4, supporting plate 5, low position sensor 6 and level sensor 7, at least one baffle plate 4 is provided between the main platform 1 and bridge platform 2, supporting plate 5 is provided on the main platform 1, and the supporting plate One end of the plate 5 is fixedly connected with the main platform 1, the other end exposes the main platform 1 and is placed under the baffle 4, the baffle 4 is hinged with the bridge platform 2, the two ends of the baffle 4 are free ends, and one end of the baffle 4 Facing the supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com