Food inspection sample storage equipment with classification function

A food inspection and sample technology, applied to impact-sensitive items, types of packaging items, bottle/can parts, etc., can solve problems such as unfavorable sample inspection, unstable container placement, crystallization, etc., and achieve flexible expansion and change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

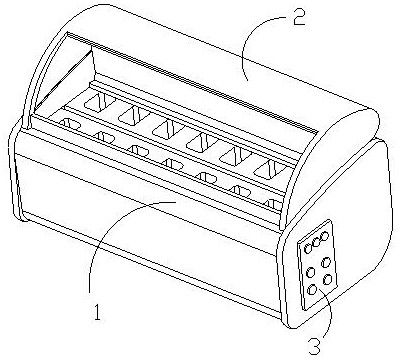

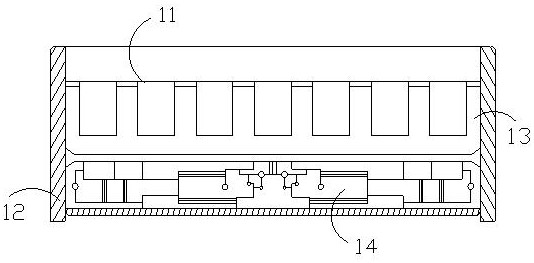

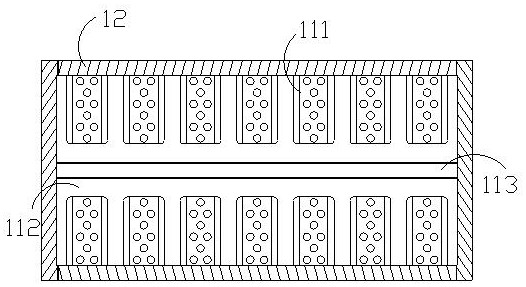

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032] The present invention provides a food inspection sample storage device with a classification function, the structure of which is provided with a cabinet body 1, a flip cover 2, and a control panel 3, the flip cover 2 is located above the cabinet body 1, and the control panel 3 is fixedly installed on the outside of cabinet 1.

[0033] The cabinet 1 is provided with a storage rack 11, an outer frame 12, a chamber 13, and a control circuit 14. The flip cover 2 is located above the storage rack 11, and the control panel 3 is fixedly installed on the outside of the outer frame 12. The outer frame 12 is fixedly connected to the outer periphery of the storage rack 11, the chamber 13 and the outer frame 12 are an integrated structure, and the control circuit 14 is located below the chamber 13.

[0034] Wherein, the storage rack 11 is provided with a storage device 111, a carrier plate 112, and an air channel 113, the ...

Embodiment 2

[0041] as attached Figure 8 to attach Figure 9 Shown:

[0042] Wherein, the auxiliary device q2 is provided with a telescopic rod q21, a pendulum block q22, and a fixed block q23, the telescopic rod q21 is connected with the shaft rod q3, the middle end of the pendulum block q22 is hingedly connected with the fixed block q23, and the The telescopic rod q21 and the fixed block q23 are an integrated structure and move below it. The telescopic rod q21 is flexible. The stretchability facilitates expansion and contraction deformation of the auxiliary contact ring q1, so that the pendulum block q22 is in contact with the outside of the vessel, and its small swing is beneficial to provide a certain shaking effect for the vessel.

[0043] Wherein, the pendulum block q22 is provided with an arc block c1, a vibrating ball c2, and a rolling ball c3. The rolling ball c3 moves inside the arc block c1, the arc block c1 has an arc-shaped structure, and its interior is in an empty state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com