Device and method for monitoring erosion state of converter lining on line in real time

A converter lining and real-time monitoring technology, which is applied in the manufacture of converters, etc., can solve problems such as the difficulty in realizing real-time feedback of converters, affecting the smelting cycle of converters, and affecting the personal safety of staff, achieving high accuracy, high safety, and intelligence. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

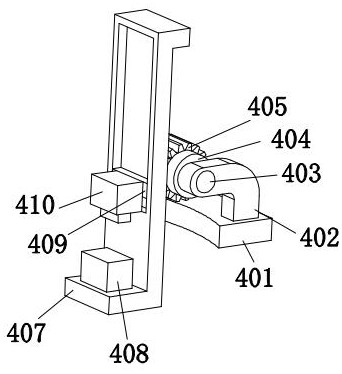

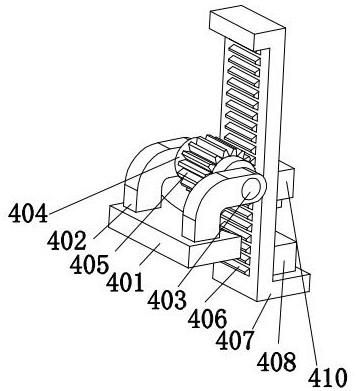

[0039] see Figure 1-6 , a device for online real-time monitoring of the erosion state of the converter lining, comprising a fixed seat 1, a furnace body 2 is fixedly installed on the upper end surface of the fixed seat 1, a furnace lining 3 is fixedly installed on the inner side wall of the furnace body 2, and a furnace body 2 is installed above the furnace body 2 Drive mechanism 4.

[0040] Specifically, the drive mechanism 4 includes a fixed plate 401, a bracket 402 is fixedly installed on the upper end surface of the fixed plate 401, and a drive shaft 403 is connected to the inside of the bracket 402 for rotation, and the drive shaft 403 is externally connected to a driver, which can drive the drive The wheel 404 rotates to provide a power source for the work of the driving mechanism 4. The peripheral surface of the driving shaft 403 is sleeved with a driving wheel 404. The peripheral surface of the driving wheel 404 is fixedly equipped with a driving tooth 405, and the dr...

Embodiment 2

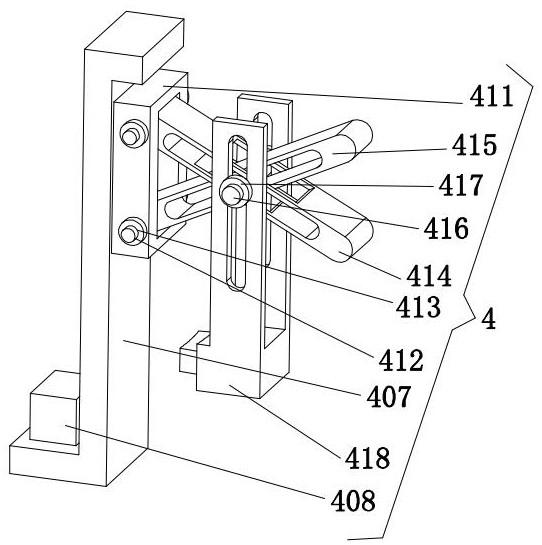

[0053] The difference between this embodiment and embodiment 1 is that the structure of the driving mechanism 4 is different, and the rest of the mechanisms are the same. Such as Figure 7 and Figure 8 As shown, in this embodiment, the driving mechanism 4 includes a fixed block 411, the fixed block 411 is connected with a rotating plate 414 and an adjusting plate 415 through a connecting rod 412, and the two ends of the connecting rod 412 are detachably connected with a fixing piece 413, and the rotating plate 414 and the adjusting plate 415 are connected through the positioning shaft 416, and the rotating plate 414 and the adjusting plate 415 are connected with the limiting plate 418 through the positioning shaft 416, the two ends of the positioning shaft 416 are detachably installed with a positioning piece 417, and the connecting rod 412 The connection stability between the rotating plate 414 and the adjusting plate 415 and the fixed block 411 can be ensured under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com