Manufacturing method of composite corrosion-resisting steel

A production method and corrosion-resistant steel technology, applied in the manufacture of converters, etc., can solve the problems of large alloy addition, high tapping temperature, and high production costs, and achieve the effects of improving absorption rate, ensuring continuity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

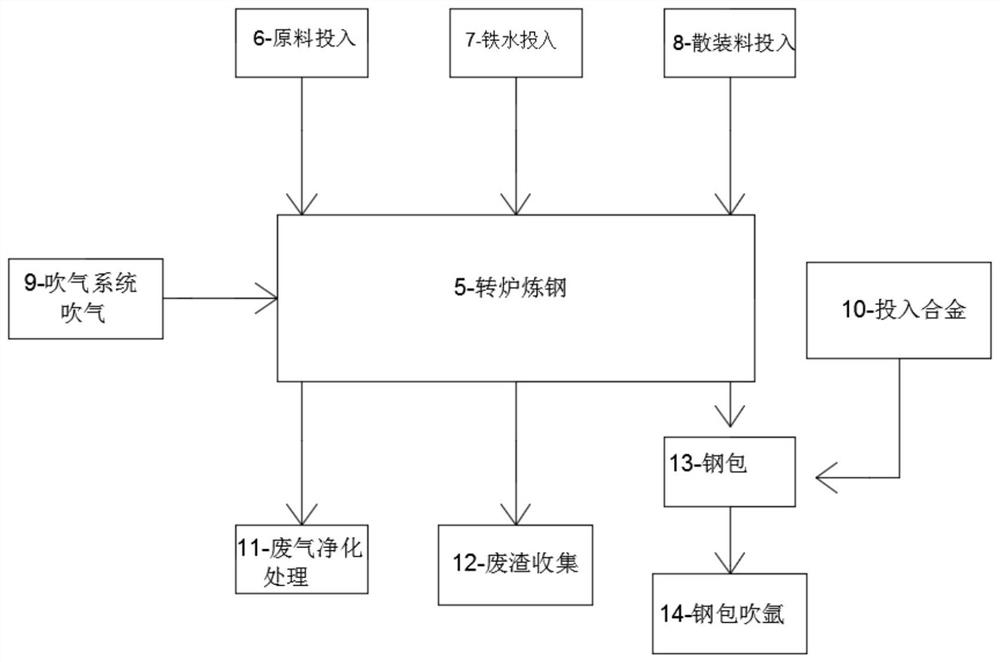

[0029] see figure 1 , a method for manufacturing a composite corrosion-resistant steel provided in the embodiment of the present invention, the manufacturing method for the composite corrosion-resistant steel comprises the following steps:

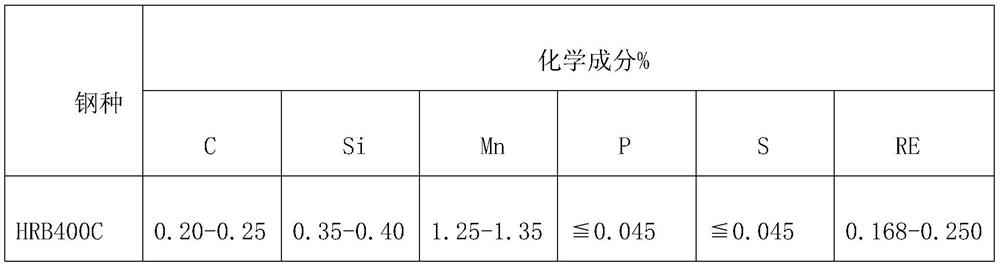

[0030] The selection of raw materials for the production of composite corrosion steel, the steelmaking of the selected raw materials through the converter, the molten steel produced by the converter is passed through the large ladle turntable, the tundish, the mold, and the rare earth wire is fed into the mold for continuous casting process production. Tapping the billet and rolling the prepared billet; the chemical composition of the prepared composite corrosion-resistant steel is controlled as follows:

[0031]

[0032] Further, the raw material selection step for making composite corrosion steel includes:

[0033] The raw materials selected to make composite corrosion steel are divided into main raw materials, auxiliary raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com