A kind of low V microalloying superfine dispersed phase high-strength steel and its preparation method

A technology of microalloying and dispersing precipitation, applied in ultrafine dispersing precipitation high-strength steel and its preparation, in the field of low V microalloying precipitation, it can solve the problem that there is little research on the characteristics of precipitation time, the influence of added amount of steel performance, Improve the cost and other issues to achieve the effect of low application cost, strong economic applicability, and simple heat treatment process

Active Publication Date: 2022-06-03

TAIYUAN UNIV OF TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Through the review of existing literature and patents, it is found that the improvement of the performance of steel is based on the composition of carbon-manganese structural steel, by adding microalloying elements and adopting controlled rolling and controlled cooling technology or by changing the C content in the steel However, there are some problems in these processes. For example, in some studies, the performance of steel is improved by adding microalloying elements. Only by adding Ti and Mo at the same time, The yield strength of the steel will reach the required value, which not only increases the cost of production, but also the addition of Mo element has a greater impact on the properties of the steel, which brings some problems to the smelting of steel

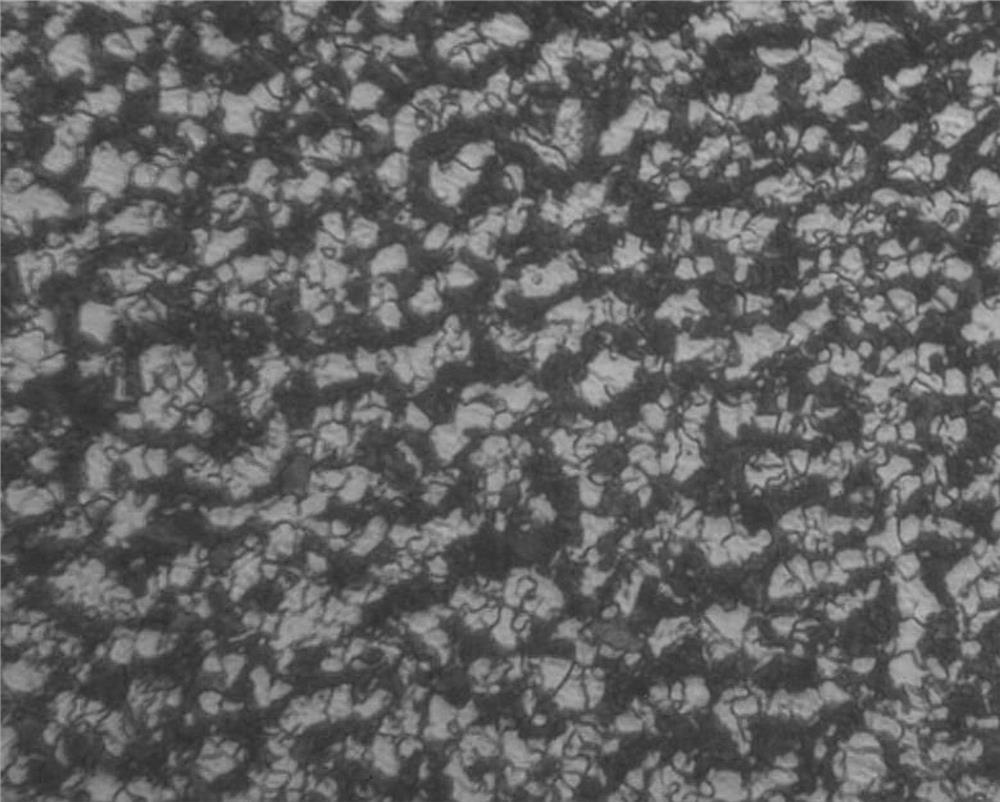

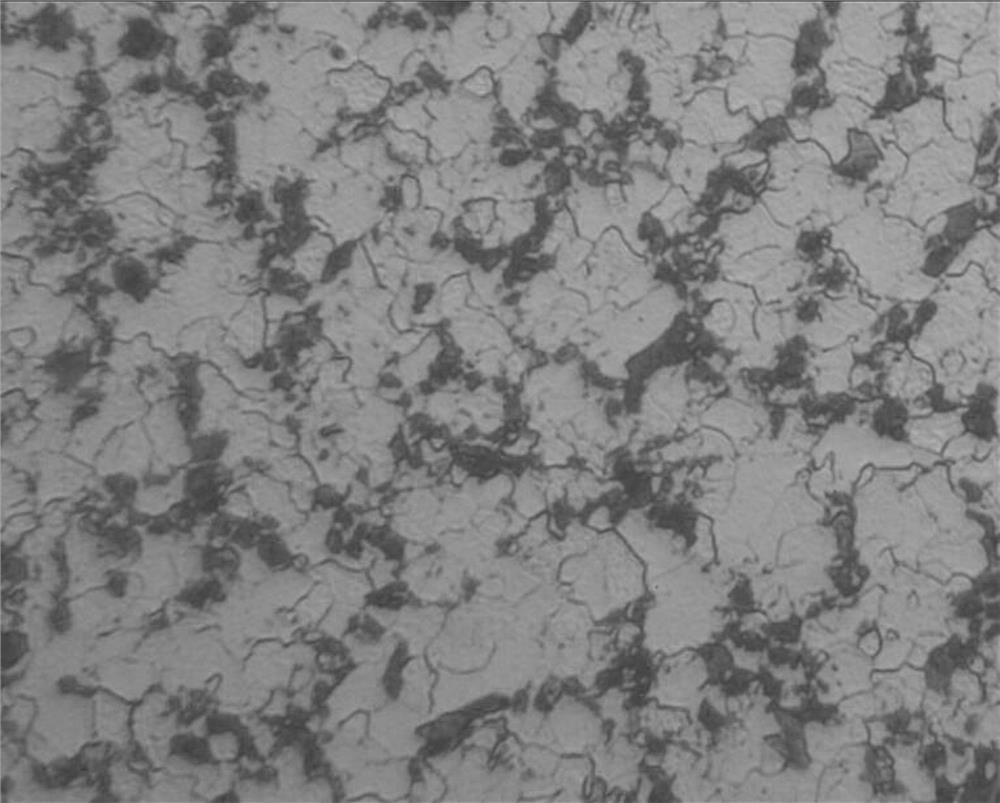

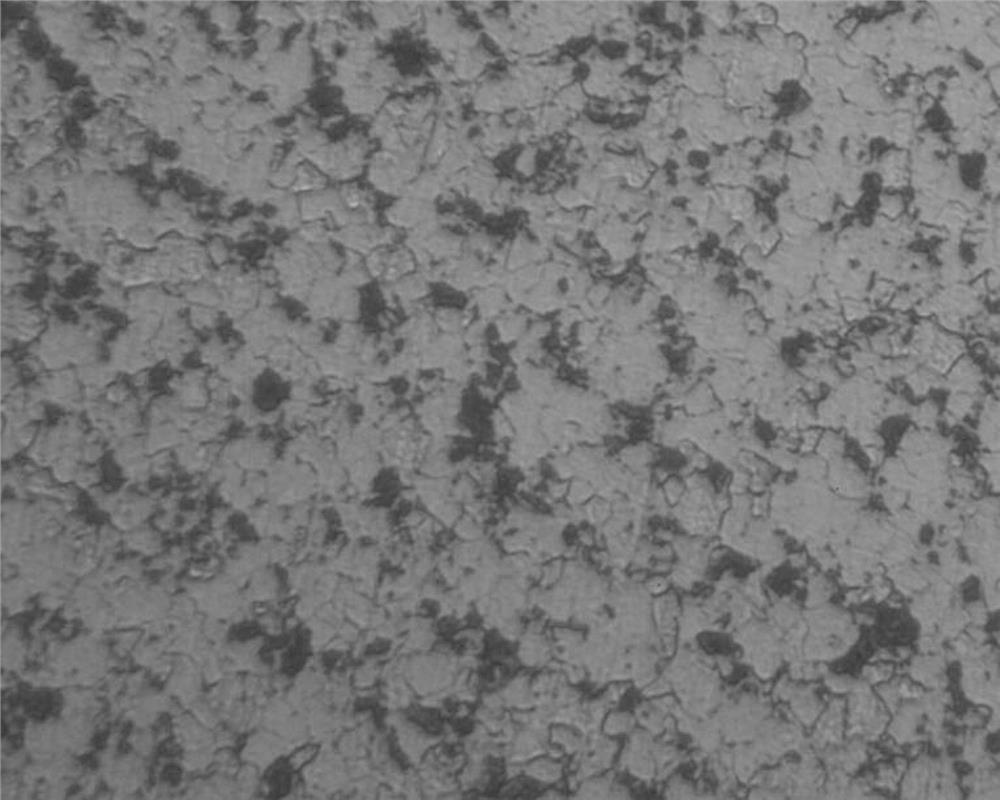

In fact, how to make the dissolved alloy elements dispersible and finely precipitated through the heat treatment process is the key to the strengthening effect of trace alloy elements. However, after the added elements are dissolved back into the steel during the smelting process, the subsequent precipitated phase precipitation rules In particular, there are few studies on the correlation between precipitation temperature, precipitation time, and characteristics of precipitated phases.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of ultra-fine dispersed precipitated phase high-strength steel and its preparation method, specifically a low V microalloyed ultra-fine dispersed precipitated phase high-strength steel and its preparation method, which solves the technical problems in the background technology, the preparation method In order to obtain steel slabs after mixing the various element components according to the nominal composition ratio, the smelted steel slabs are then processed by conventional heating furnace process or direct rolling process. After the treatment, the steel ingots cooled to room temperature are heated and heated at a certain temperature Holding for a certain period of time allows V to completely dissolve into the steel ingot, and then cooling at a certain temperature and holding for a certain period of time allows V to be completely precipitated, forming V (C, N) uniformly dispersed and fine precipitates to provide low V microalloyed super Fine dispersed precipitate phase high strength steel. This method exerts the precipitation strengthening effect of the V(C, N) precipitates, so that the precipitates can be uniformly dispersed in the matrix to achieve the effect of dispersion strengthening, and prepare high-strength and high-plasticity high-strength steel.

Description

A kind of low-V microalloyed ultra-fine disperse precipitation high-strength steel and preparation method thereof technical field The invention belongs to the technical field of ultrafine disperse precipitation phase high-strength steel and preparation method thereof, relate to low V microalloying The precipitation phase is specifically a low-V microalloyed ultra-fine dispersed precipitation phase high-strength steel and a preparation method thereof. Background technique By adding different alloying elements in steel to improve the performance of steel is a more commonly used technology at this stage, using The respective properties of different alloying elements enable them to play their respective roles in the steel, which can improve the performance of the steel. However, due to the different melting points of various elements, adding a certain amount of alloying elements to the steel may cause the alloying elements to be difficult to It is completely dissolved in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/38C22C38/24C22C33/04C21D1/28C21D6/00

CPCC22C38/02C22C38/38C22C38/24C22C38/001C22C33/04C21D1/28C21D6/008C21D6/005C21D6/002C21D2211/005C21D2211/009C21D2211/004Y02P10/20

Inventor 韩培德寻懋年刘鹏张玺成齐治畔

Owner TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com