Method for manufacturing GaAs-based MHEMT device with grid length of 200nm

A device and gate length technology, applied in the field of compound semiconductor devices, can solve problems such as limiting the application of MHEMT and restricting the performance of MHEMT devices, and achieving the effects of strong reliability, simple and easy process, and strong economical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

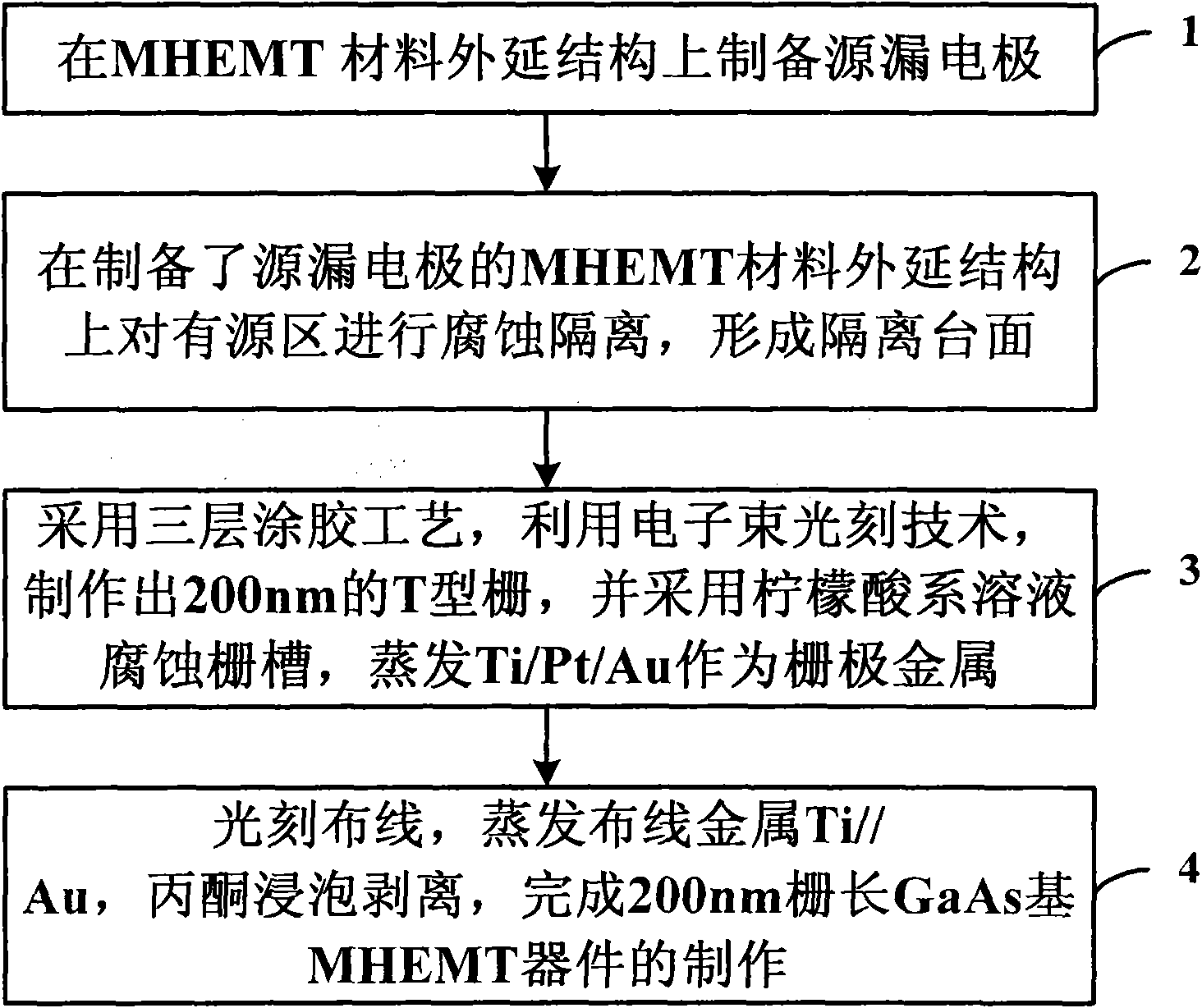

[0038] Such as figure 1 as shown, figure 1 It is a flow chart of a method for making a GaAs-based MHEMT device with a gate length of 200nm provided by the present invention, and the method includes the following steps:

[0039] Step 1: Prepare source and drain electrodes on the epitaxial structure of the MHEMT material; the specific process includes:

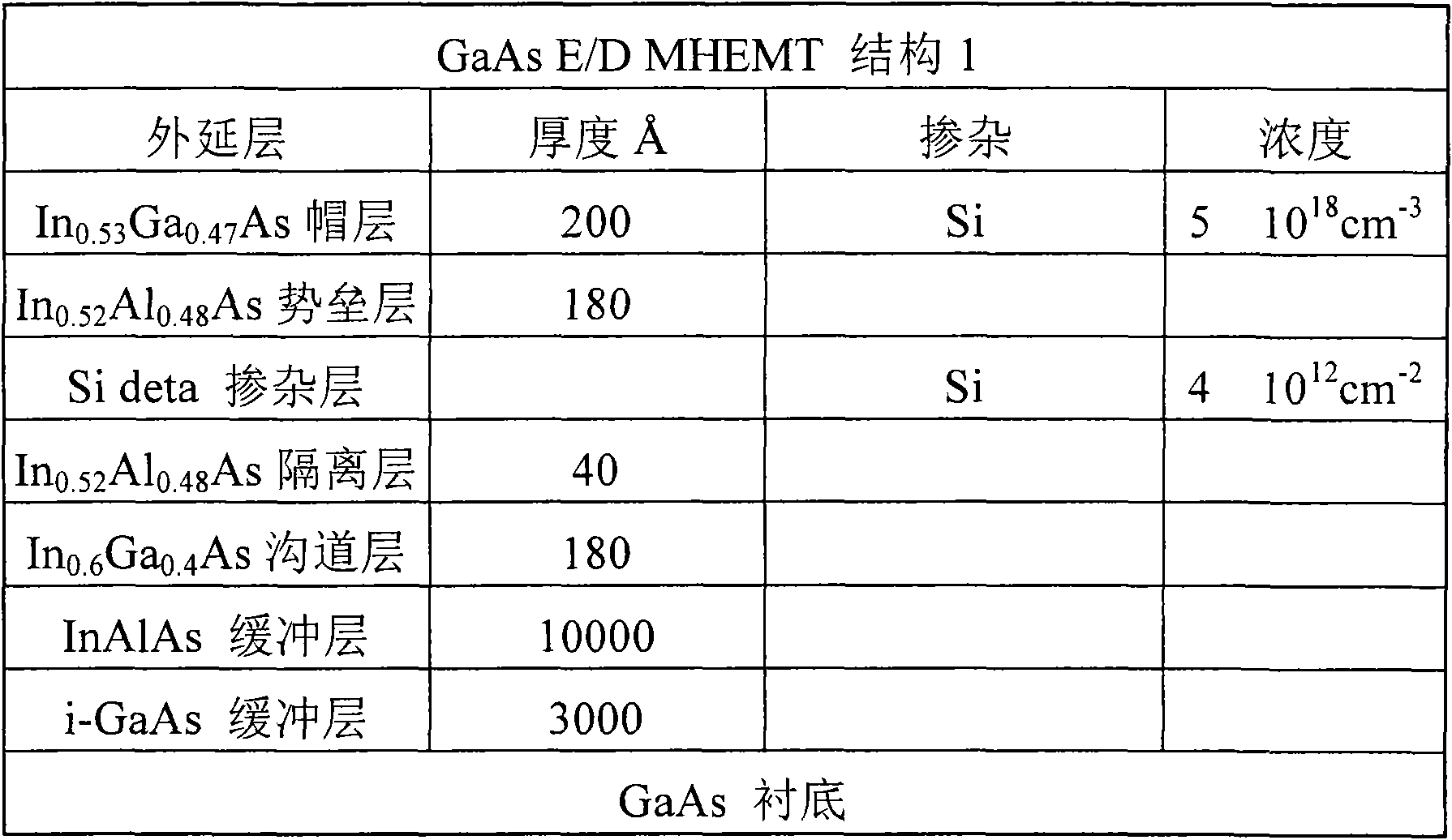

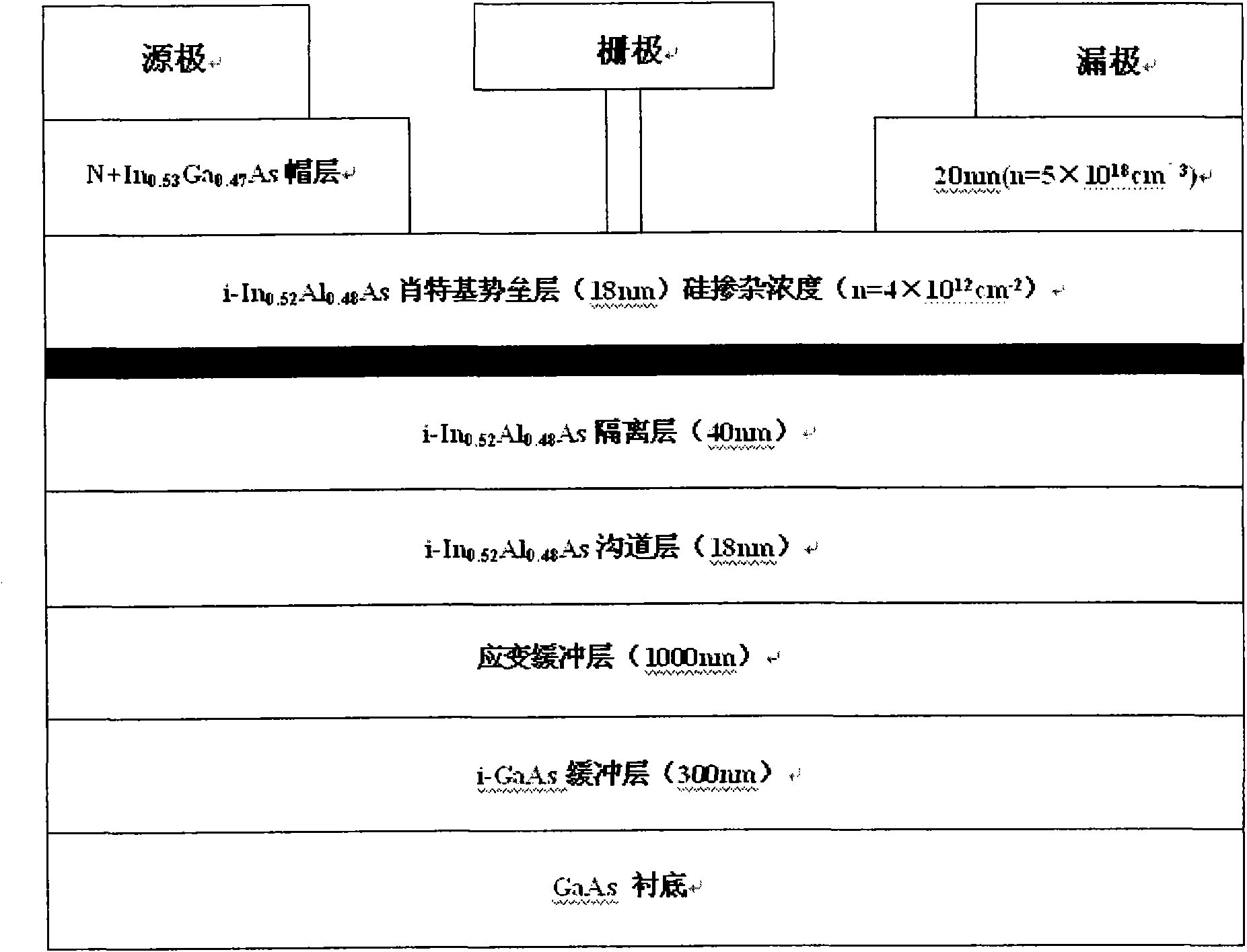

[0040] In the MHEMT material epitaxial structure (such as figure 2 As shown) apply collagen glue AZ5214 on top, 3500 rpm, apply for 1 minute, the coating thickness of the original glue AZ5214 is about 1.6 μm, 95 ℃ hot plate, 90 seconds, source and leak version, small machine exposure for about 20 seconds, AZ5214 Developing solution for about 60s, rinse with water, apply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com