Construction method of pre-stressed anchor cable frame beam structure

A technology of prestressed anchor cable and construction method, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problems of surface slope deformation, anchor cable prestress loss, damage, etc., and achieve the effect of controlling deep damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

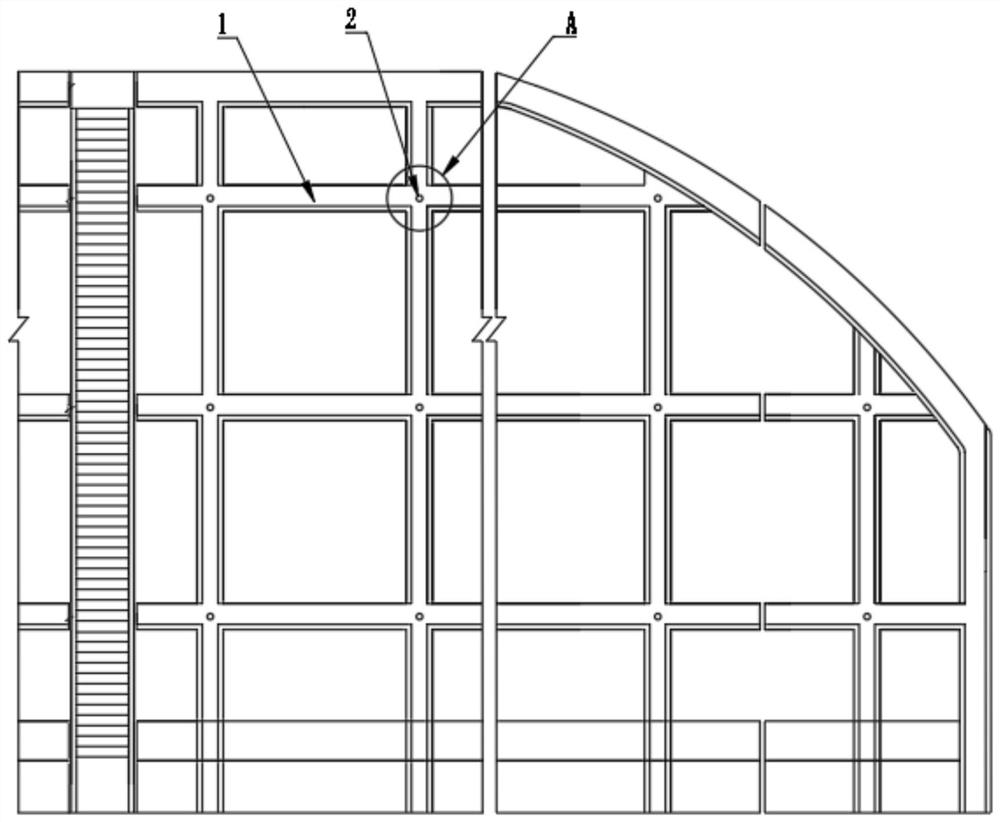

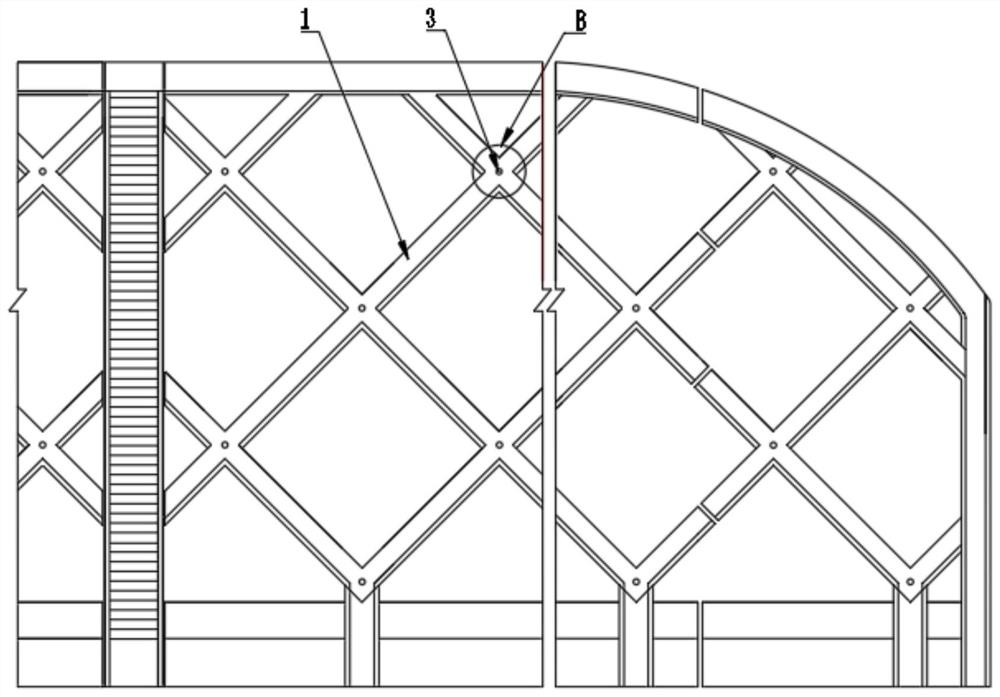

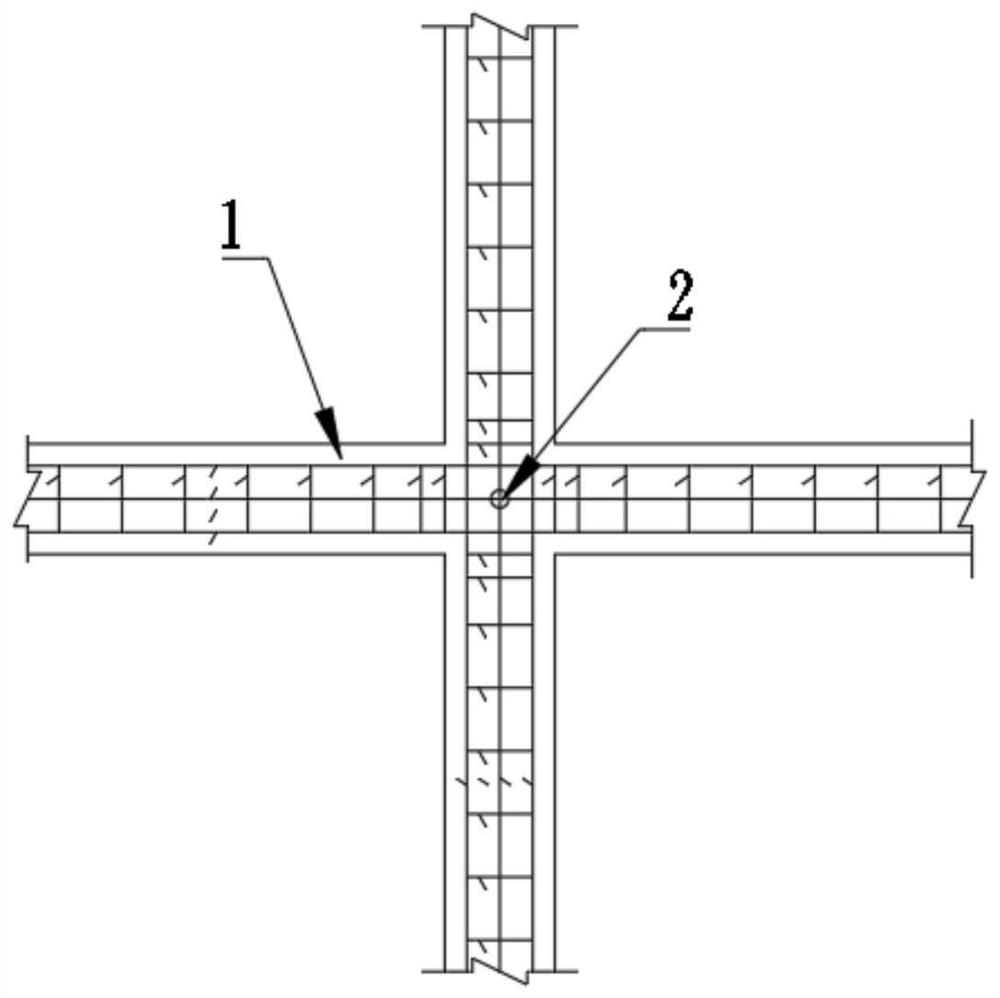

[0036] This embodiment provides a construction method for a prestressed anchor cable frame beam structure, such as Figure 1 to Figure 4 As shown, among them, image 3 The partial view A provided for the present invention is also the reinforcement diagram at node A, Figure 4 The partial view B provided for the present invention is also the reinforcement diagram at the node B; including the following specific steps:

[0037] 1. Excavation of the slope: Before the construction of the anchor cable project, the slope should be excavated according to the construction plan to the elevation of the slope platform of this level. Before excavation, construct slope intercepting ditches first to prevent slope erosion. Excavation of side slope earth and stone construction should be excavated in layers, reserve a slope protection layer, and do side slope protection in time according to the design requirements. The excavation of the side slope should be straight, smooth and flat, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com