Assembled suspended ceiling veneer and mounting method

A prefabricated and suspended ceiling technology, applied in ceilings, building components, buildings, etc., can solve the problems of single and simple structure and poor aesthetics, and achieve the effect of high safety, improved aesthetics, and rich structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

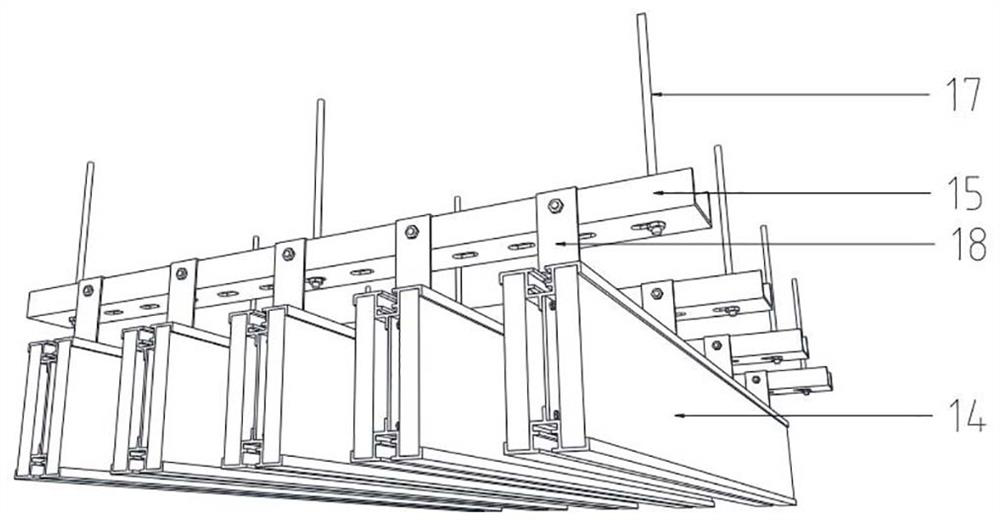

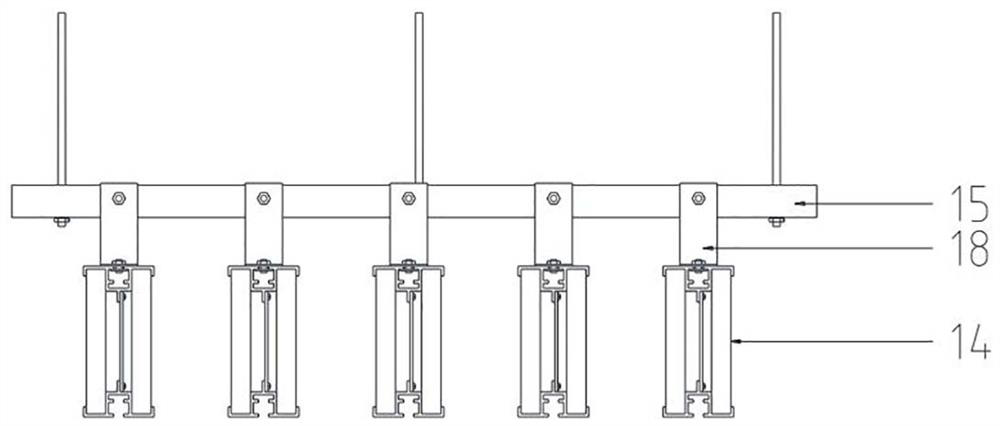

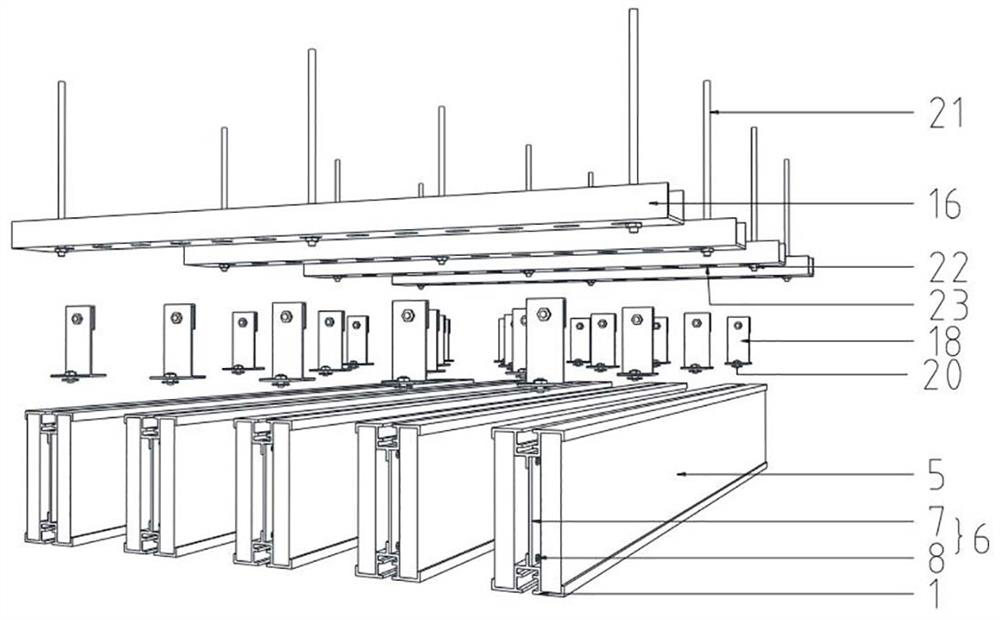

[0043] Such as Figure 1~8 As shown, a prefabricated suspended ceiling finish includes a keel assembly 15, on which a number of metal pendants 18 are suspended, and several metal pendants 18 are divided into one group, and are hung and connected to the suspended ceiling finish group 14 located below. .

[0044] Wherein: the keel assembly 15 includes a U-shaped keel 16, the bottom of the U-shaped keel 16 is provided with some through holes 23, and the U-shaped keel 16 passes through the through holes 23 through several groups of hoisting components 17, so as to be installed and fixed on the top of the wall.

[0045] Wherein, the hoisting assembly 17 includes a suspender 21 , and a load-bearing member 22 is arranged at the bottom of the suspender 21 . The diameter of the suspension rod 21 is smaller than the diameter of the through hole 23 , and the diameter of the load-bearing member 22 is larger than the diameter of the through hole 23 , so that the load-bearing member 22 can...

Embodiment 2

[0056] A method for installing a prefabricated suspended ceiling finish, comprising the following steps:

[0057] S.1 Pass the suspender 21 through the through hole 23 at the bottom of the U-shaped keel 16, so that the load-bearing member 22 supports the U-shaped keel 16, and then fix the upper end of the suspender 21 to the wall to complete the installation of the keel assembly 15;

[0058] S.2 Connect the two convex parts 1 to each other through the connecting part 6 to form a whole, and then insert the veneer 5 into the opposite clamping groove 2, so that the components are combined and connected to each other to obtain the ceiling veneer group 14;

[0059] S.3 Embed the clamping pieces 20 at the lower ends of several metal pendants 18 into the lifting groove 3;

[0060] S.4 Lift the ceiling finish group 14 and the metal pendant 18, and fix the hook 19 of the metal pendant 18 with the U-shaped keel 16, thereby completing the installation of the entire ceiling finish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com