Drilling device for mine engineering blasting

A drilling device and mining engineering technology, applied in drilling tools, directional drilling, earthwork drilling and mining, etc., can solve problems such as difficulty for construction personnel to stand firmly, reduce drilling rig efficiency, and increase construction personnel's operation difficulty, so as to improve construction safety , Improve the convenience of operation, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

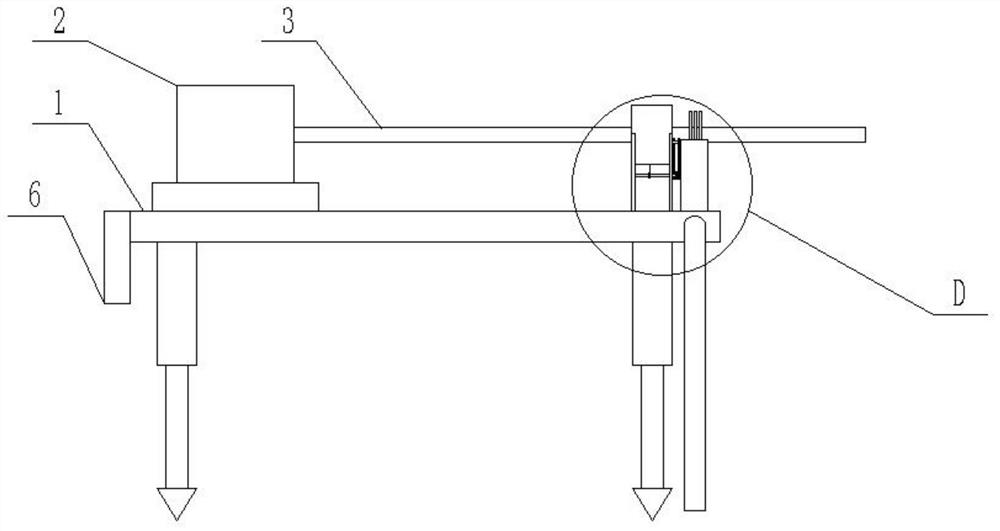

[0027] Such as figure 1 As shown, a drilling device for mine engineering blasting includes: a workbench 1, a motor 2, a drill rod 3, and a collection assembly; the motor 2 is arranged on the workbench 1, and the motor 2 and the workbench 1 pass through the guide assembly sliding connection; the drill rod 3 is horizontally arranged above the workbench 1, and the drill rod 3 is connected to the output shaft of the motor 2 for drilling; the collection assembly is arranged at the end of the drill rod 3 away from the motor 2, It is used to collect the mud-water mixture brought out by the drill pipe 3 from the hole; the mud-water mixture brought out by the drill pipe can be collected centrally through the collection component, so as to avoid flowing to the ground and affect the safety of construction personnel;

[0028] The collection assembly includes: a support set on the workbench 1 and directly below the drill pipe 3, the support is connected to the workbench 1; On both sides, ...

Embodiment 2

[0033] Such as Figure 5 As shown, in order to further improve the convenience of operation, the wind brought out by the drill pipe is used as the power through the annular air guide channel to drive the cleaning wheel to work and improve the utilization efficiency of resources; it can not only collect the mud-water mixture on the drill pipe, but also reduce the wind. Speed, to avoid the impact on people's glasses, to facilitate the observation of the drilling situation.

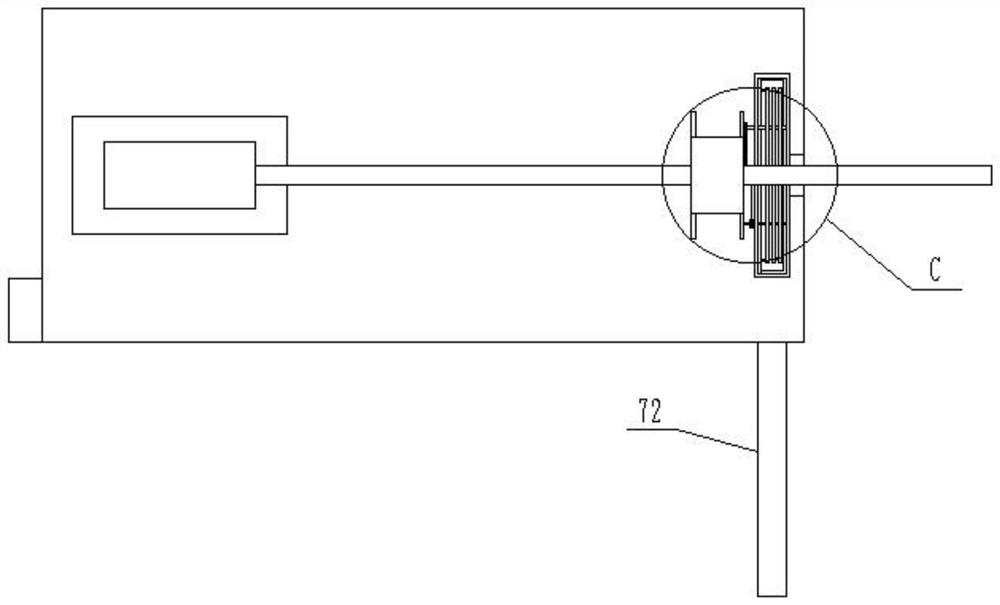

[0034] Preferably, the drive mechanism includes an inner tube 21 sleeved on the drill pipe 3 and coaxial with it, the outer side of the inner tube 21 is sleeved with an outer tube 22 and forms an annular air guide channel with it, the outer wall of the outer tube 22 and the bracket Connecting, on the annular air guide channel, a plurality of fan leaves 23 are evenly arranged radially with its axis as the center, and the outer wall of the inner tube 21 and the inner wall of the outer tube 22 are respectively ...

Embodiment 3

[0036] In order to further improve the collection efficiency of the mud-water mixture, pulleys and gears are used to make the cleaning wheels on both sides rotate to the side of the drill pipe to prevent the mud-water mixture from splashing outward.

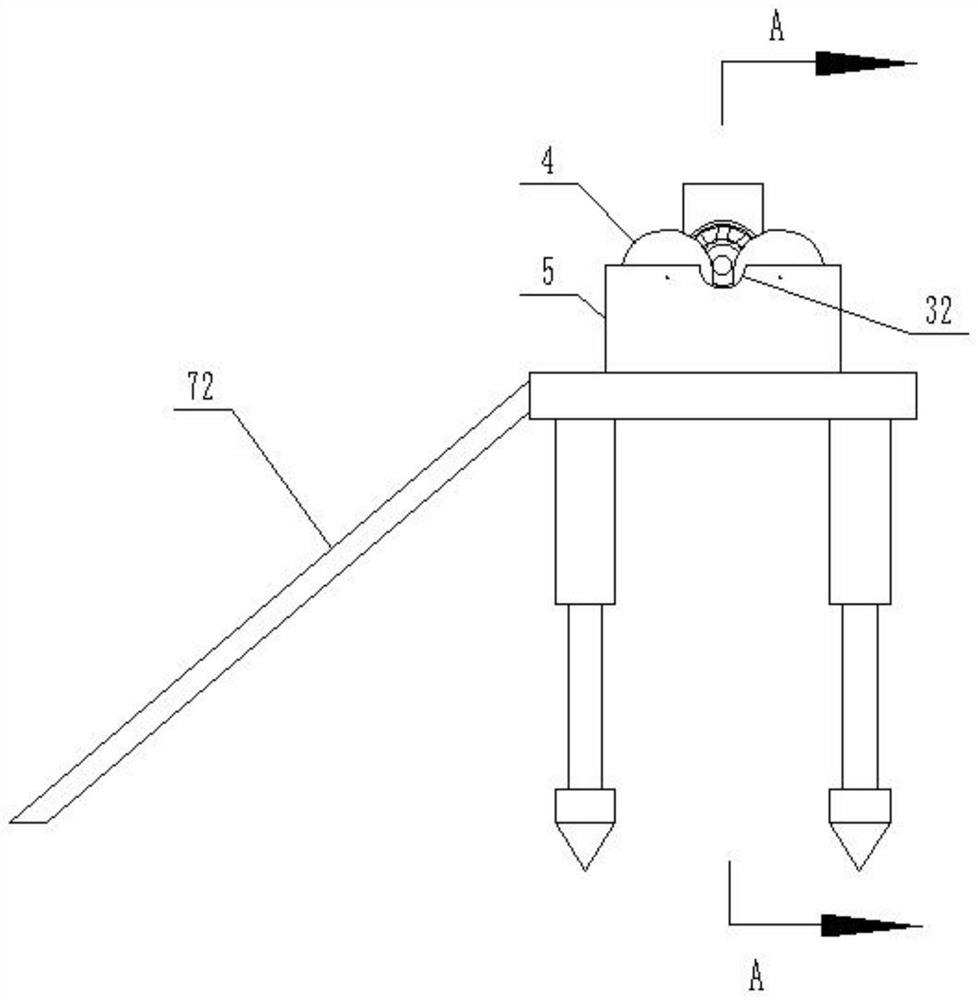

[0037] Such as figure 2 , 6 , 7, preferably, the bracket includes two first U-shaped support plates 31 arranged on the workbench 1, and the bottom of the outer tube 22 fits and fixes with the inner sides of the two first U-shaped support plates 31 respectively. connection, the bottom of the first U-shaped support plate 31 is vertically fixedly connected to the workbench 1, and the side of the collection bucket 5 away from the workbench 1 is provided with an arc-shaped groove 32 and is located directly below the drill pipe 3. The arc-shaped groove 32 Two first rotating shafts 33 are arranged symmetrically on both sides of the shaft and are parallel to the drill pipe 3. The two ends of the first rotating shaft 33 are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com