Low-oil-content sewage deoiling and desanding cyclone purification device

A technology for purifying device and oily sewage, which is applied in cyclone devices, grease/oily substance/float removal devices, and devices whose axial direction of cyclone can be reversed, etc. Separation, cyclone blockage and other problems, to achieve the effect of rich design methods, strong innovation and practicability, and easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

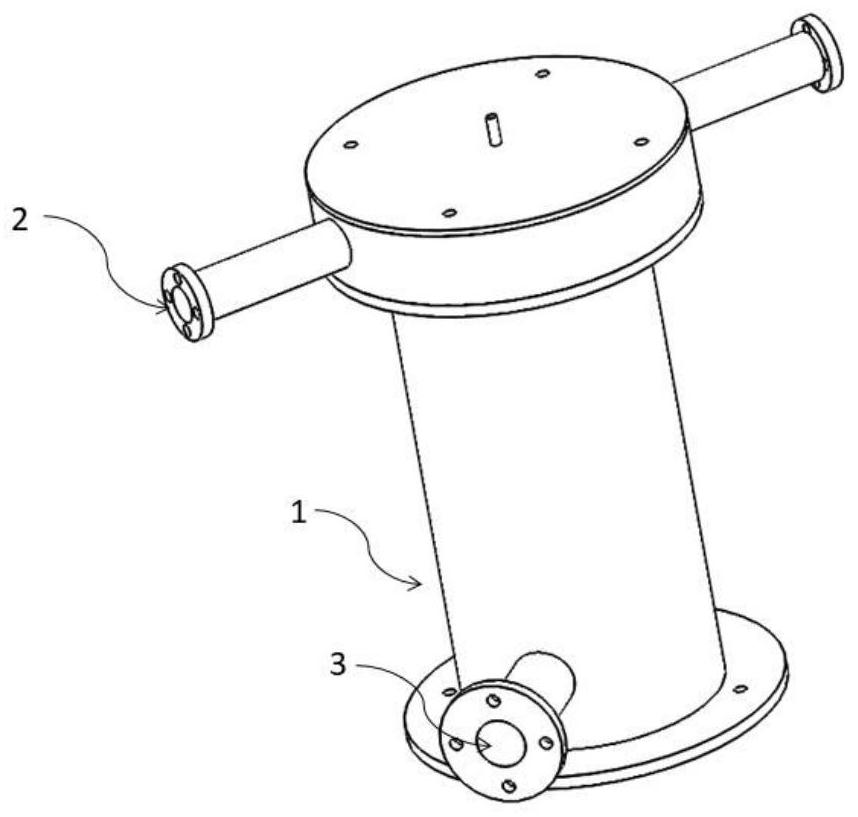

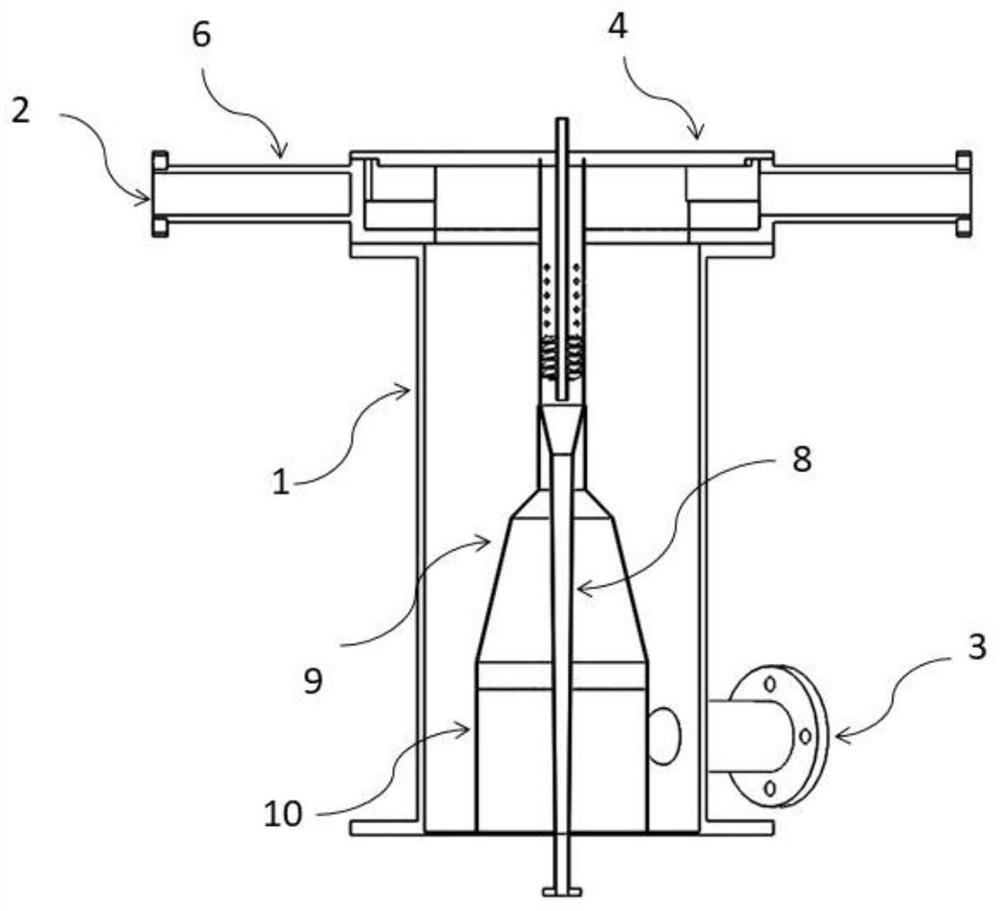

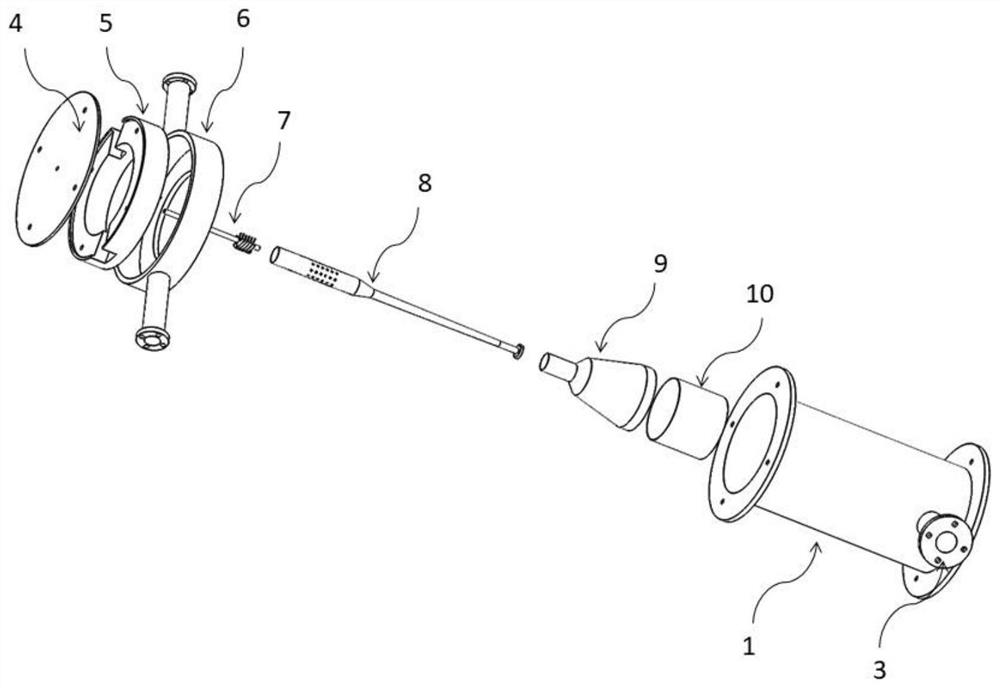

[0035] The overall appearance of the low oily sewage deoiling and desanding cyclone purification device is as follows figure 1 As shown, the device is cylindrical, with two tangential inlets 2, a sandy bottom outlet 3, figure 2 It is an overall half-sectional view of the high-efficiency deoiling and sand removal cyclone purification device for low-oily sewage. The oil-sand cyclone separation chamber 1 is a hollow structure, and the bottom is sealed. An intermediate oil-water cyclone separator 8 is installed inside to separate the oil-sand cyclone The cavity conical barrel 9 and the oil-sand cyclone separation chamber cylindrical barrel 10 are all hollow structures and welded together, and the oil-water cyclone separator 8 is penetrated in the middle, so that it is fixed. image 3 It is an exploded view of the high-efficiency deoiling and desanding cyclone purification dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com