Rotating speed and flow optimizing method and system for variable-speed operation of mixed-flow water turbine

A technology of Francis and water turbines, applied in mechanical equipment, hydropower, engine components, etc., can solve problems such as difficulty in obtaining operating characteristic curves of Francis turbines, lack of accumulation of actual operating data, etc., achieve flexible configuration and operation, and increase additional Energy gain, the effect of low difficulty of acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

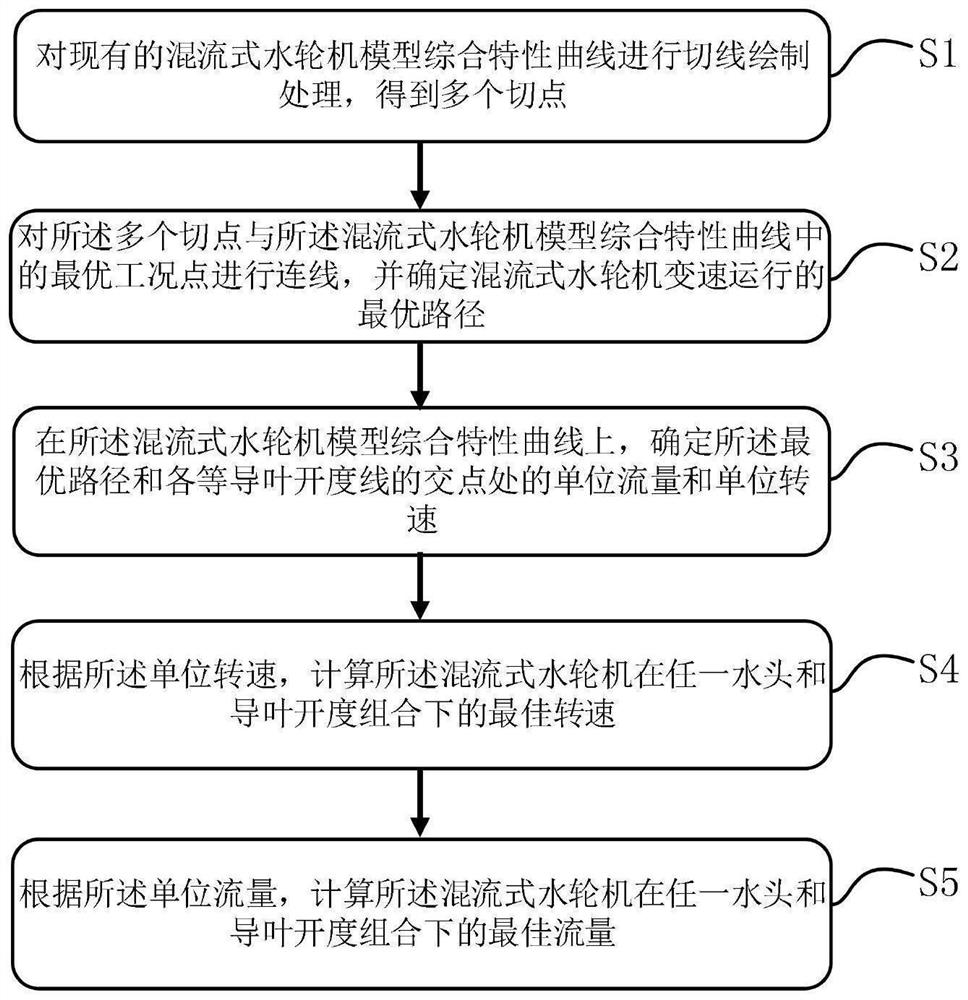

[0063] Such as figure 1 As shown, this embodiment provides a speed and flow optimization method for variable-speed operation of a Francis turbine. This method starts from the basic data of the existing Francis turbine model comprehensive characteristic curve, and derives the variable speed of the Francis turbine. The calculation method of the optimal speed and flow for unit operation can provide a certain theoretical basis and data support for the control and research of mixed flow variable speed units in power plants. The steps of this method are as follows:

[0064] Step S1 , drawing tangent lines 2 to the comprehensive characteristic curve of the existing Francis turbine model to obtain multiple tangent points 3 . Specifically include:

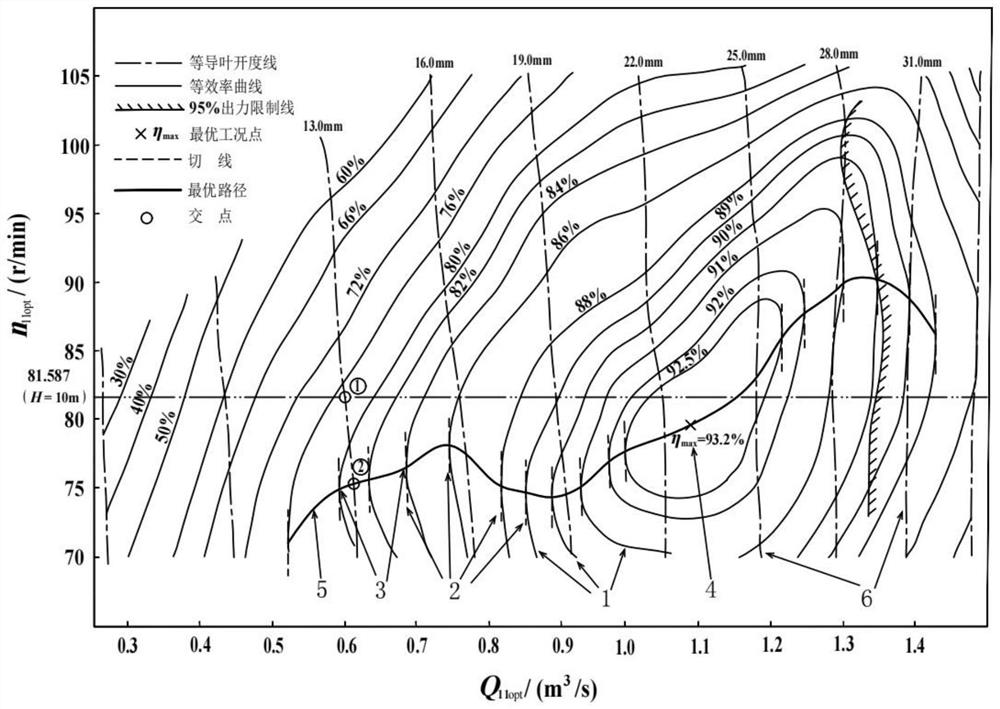

[0065] On the comprehensive characteristic curve of the Francis turbine model, along the axis Q perpendicular to the abscissa 11 tangent 2 to each equal efficiency curve circle in the integrated characteristic curve of the Francis turbin...

Embodiment 2

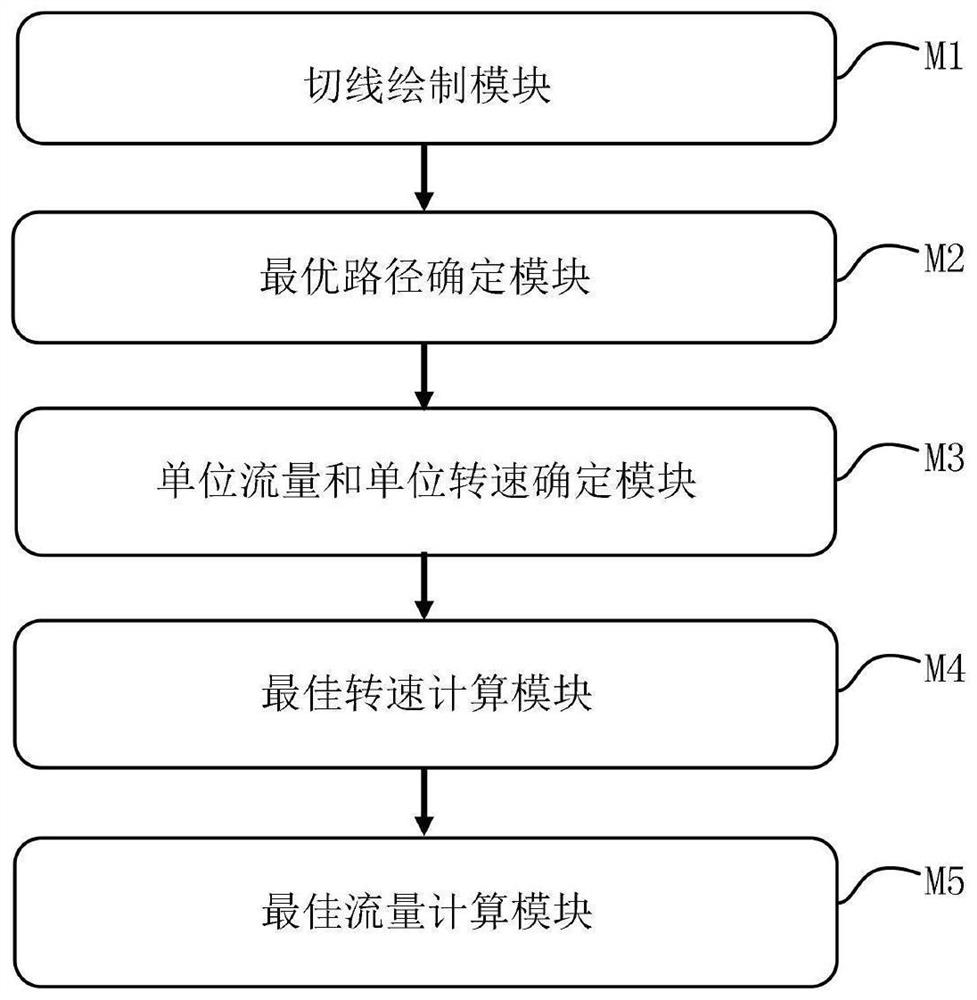

[0097] Such as image 3 As shown, this embodiment provides a speed and flow optimization system for variable speed operation of Francis turbines, and the system specifically includes:

[0098] The tangent line drawing module M1 is used for drawing tangent lines 2 on the comprehensive characteristic curve of the existing Francis turbine model to obtain multiple tangent points 3 . Specifically include:

[0099] The tangent drawing module M1 draws a tangent 2 to each equal efficiency curve circle in the comprehensive characteristic curve of the Francis turbine model along the direction perpendicular to the abscissa axis on the comprehensive characteristic curve of the Francis turbine model, The plurality of tangent points 3 are obtained; the tangent points 3 are connection points between each of the equivalent efficiency curve circles and the corresponding tangent lines 2 .

[0100] The optimal path determination module M2 is used to connect the plurality of tangent points 3 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com