An experimental device and method for measuring liquid metal two-phase flow parameters

A liquid metal and parameter measurement technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of restricting the research on the two-phase flow mechanism of liquid metal, multiple auxiliary support systems, high experimental costs, etc., and achieve the expansion of methods and ideas, and operability Strong, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

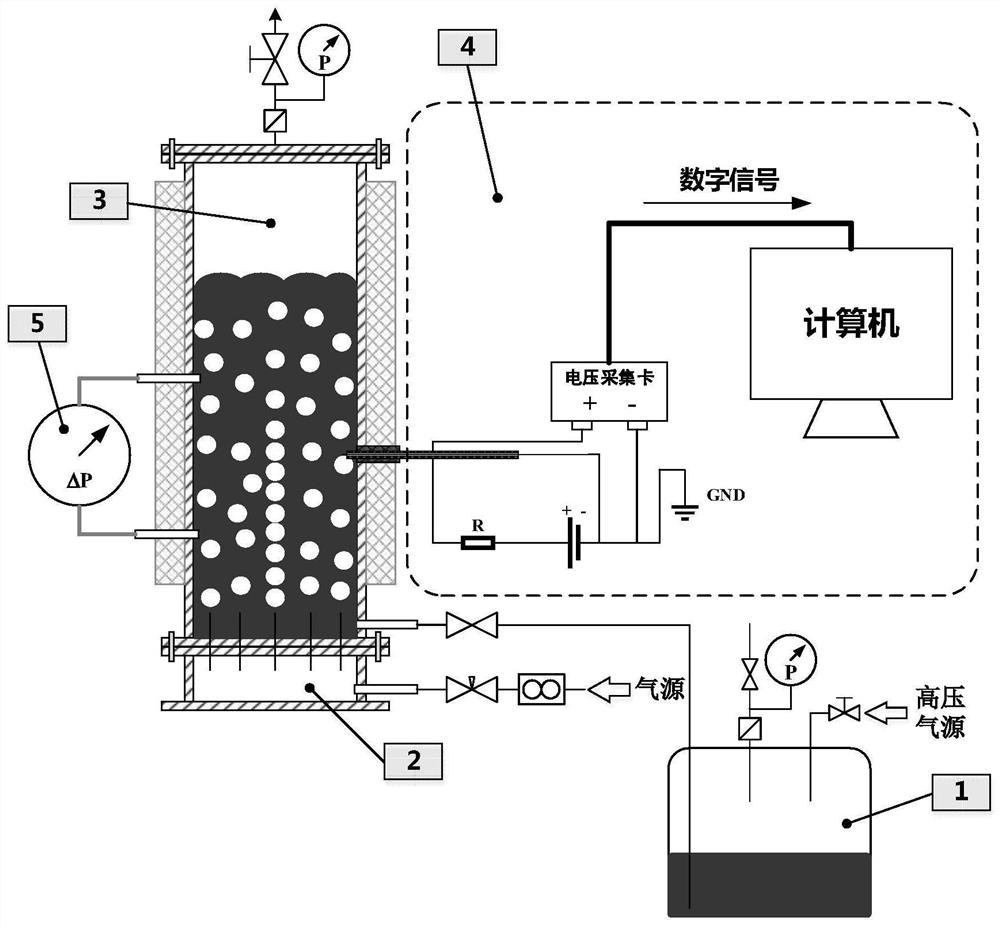

[0027] The present invention is described in detail below in conjunction with the accompanying drawings and embodiments of the description:

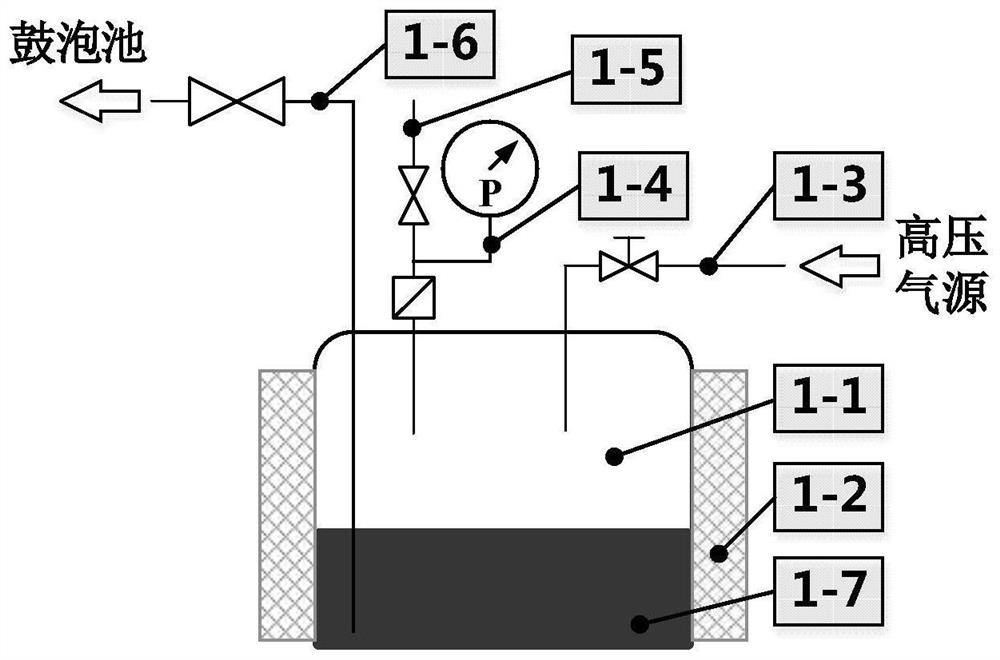

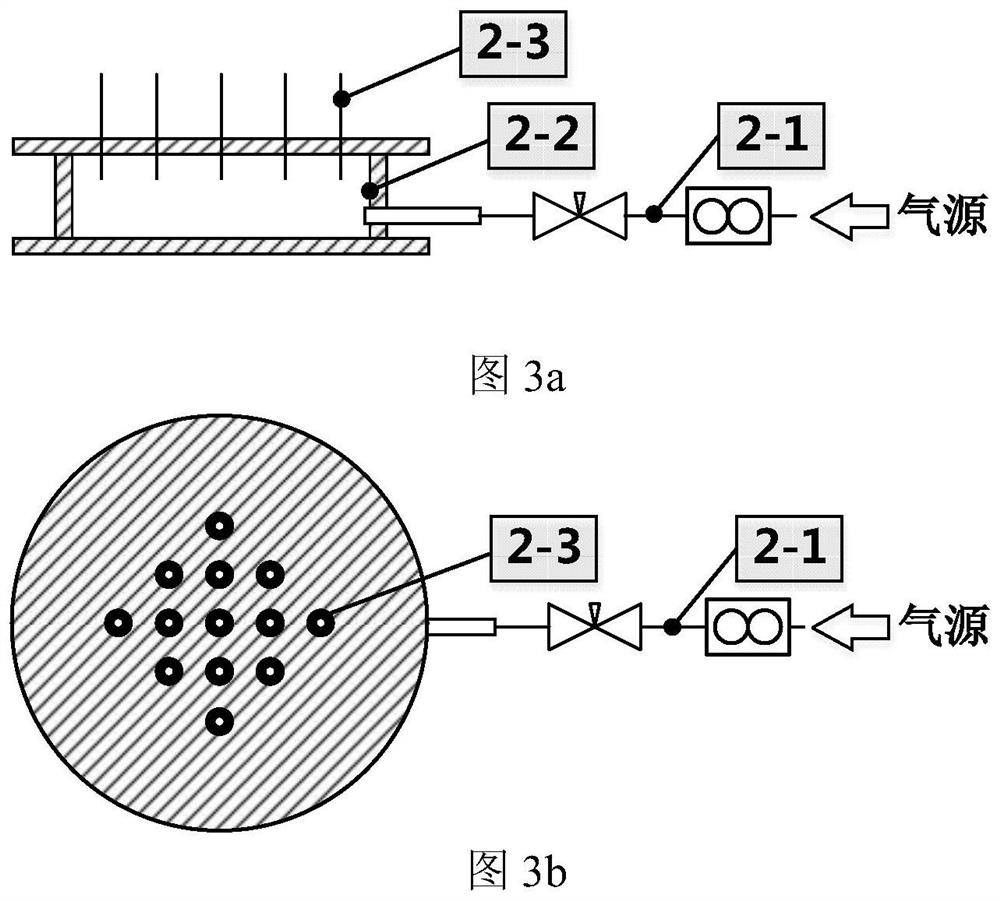

[0028] like figure 1 As shown, an experimental device for liquid metal two-phase parameter measurement of the present invention includes a liquid metal storage system 1 , a gas distributor 2 , a bubbling cell 3 , a conductivity probe system 4 and a differential pressure gauge 5 . The bubbling tank 3 is provided with a measuring hole for inserting the pressure pipe of the differential pressure gauge 5 and the conductance probe of the conductance probe system 4, and the lower end of the bubbling tank 3 is fixedly connected with the upper end of the gas distributor 2.

[0029] The liquid metal storage system 1 is used to supply / recover the liquid metal working medium to the bubbling tank 3; the gas distributor 2 is used to inject the gas phase into the liquid metal of the bubbling tank 3; the bubbling tank 3 is used to A liquid metal two-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com