Simulation test method for shrinkage of cold-shrinkable cable accessories affected by silicone grease

A technology of simulation testing and cable accessories, which is applied in the direction of measuring devices, color/spectral characteristic measurement, instruments, etc., can solve the problems of low application reference significance, and achieve the effects of strong popularity, intuitive and accurate test results, and simple and universal test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

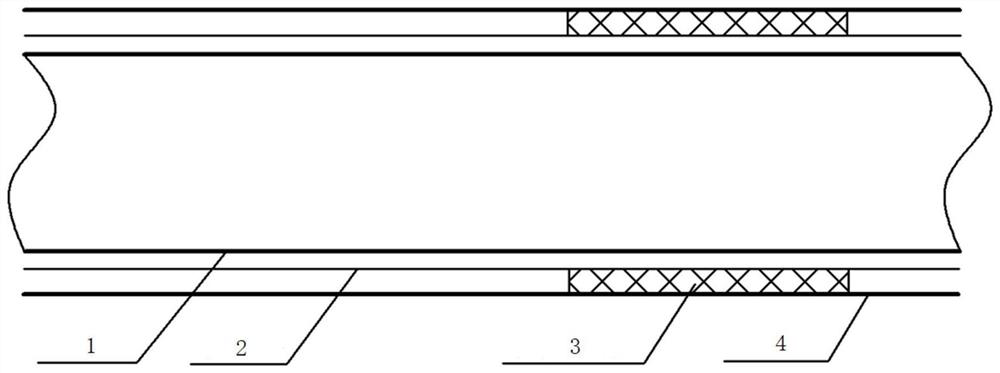

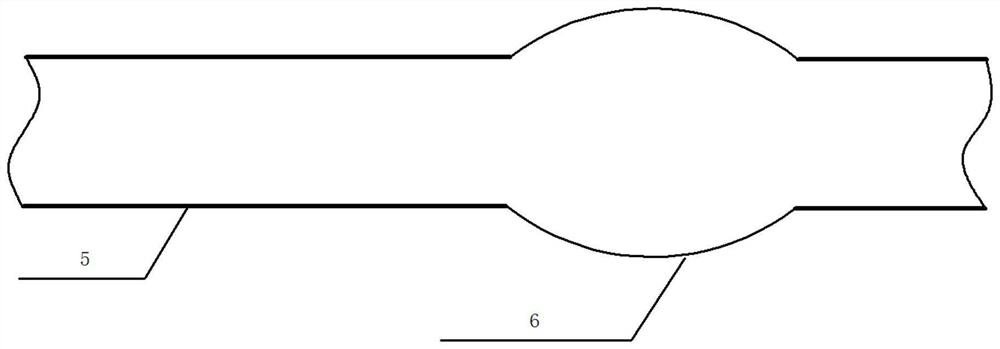

Image

Examples

Embodiment 1-4

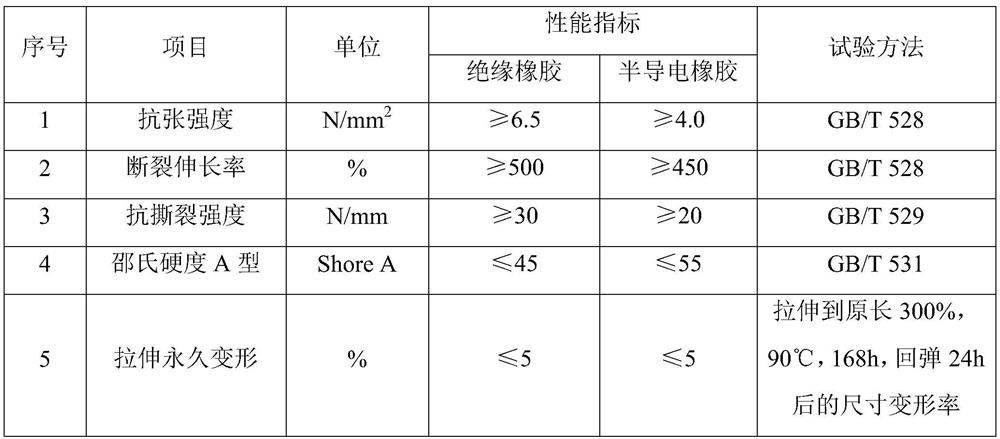

[0051] Examples 1-4 all adopt the test method shown above, wherein the selected cold shrinkable tube is No. 1 cold shrinkable tube produced by Shandong Qixing Electric Technology Development Co., Ltd. Requirements for cold-shrinkable cable accessories; 3 sample samples are made for each embodiment, and Fushunda is used in Embodiment 1 L55 / 2 grease; Embodiment 2 has adopted OFX-0203 alkylphenyl silicone oil; Embodiment 3 has adopted DR-905 insulating grease (manufacturer is Shenzhen Yi Derun Technology Co., Ltd.); Embodiment 4 has adopted DR-49F fluorosilicone grease (manufactured by Shenzhen Yiderun Technology Co., Ltd.); the indicators of the silicone grease used in Examples 1-4 all meet the relevant national standards for insulating grease for cold-shrinkable cable accessories, as shown in the following table As shown in 1:

[0052] Table 1 Main performance indicators of insulating grease for installation

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com