Electronic part detection and crimping device and detection method based on Internet of Things

A technology for electronic parts and crimping devices, which is applied to parts of electrical measuring instruments, measuring devices, casings of measuring devices, etc. problems, to achieve the effect of reducing labor and equipment costs, complete parameters, and neat arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

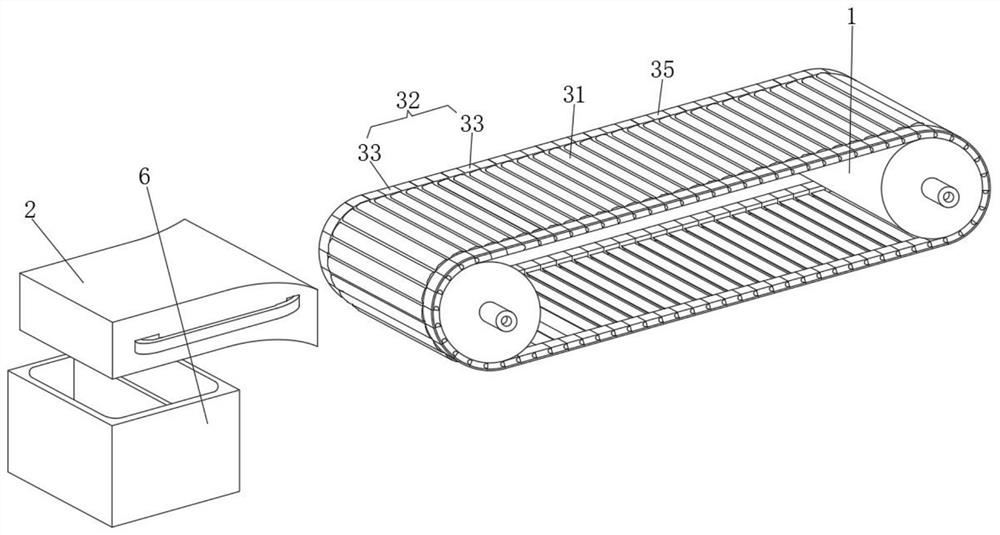

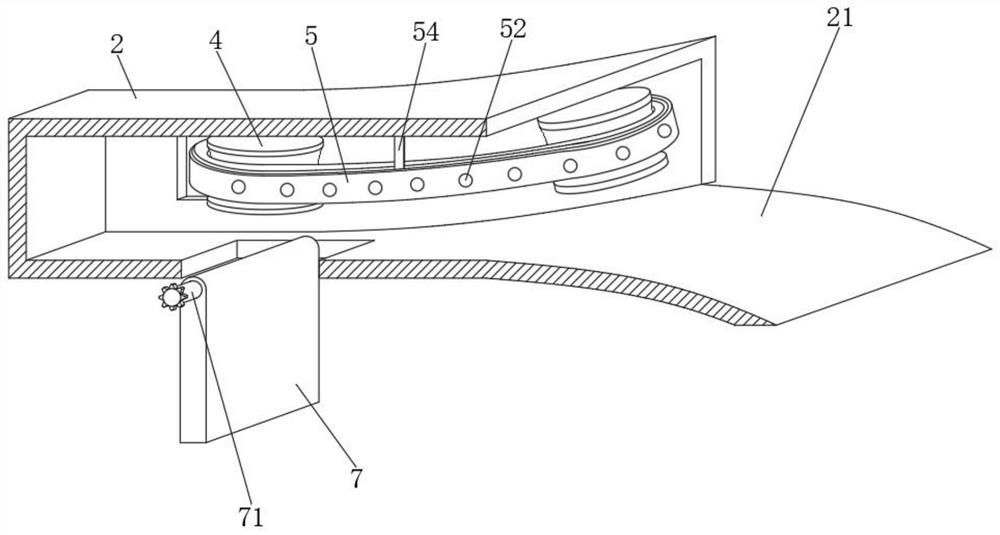

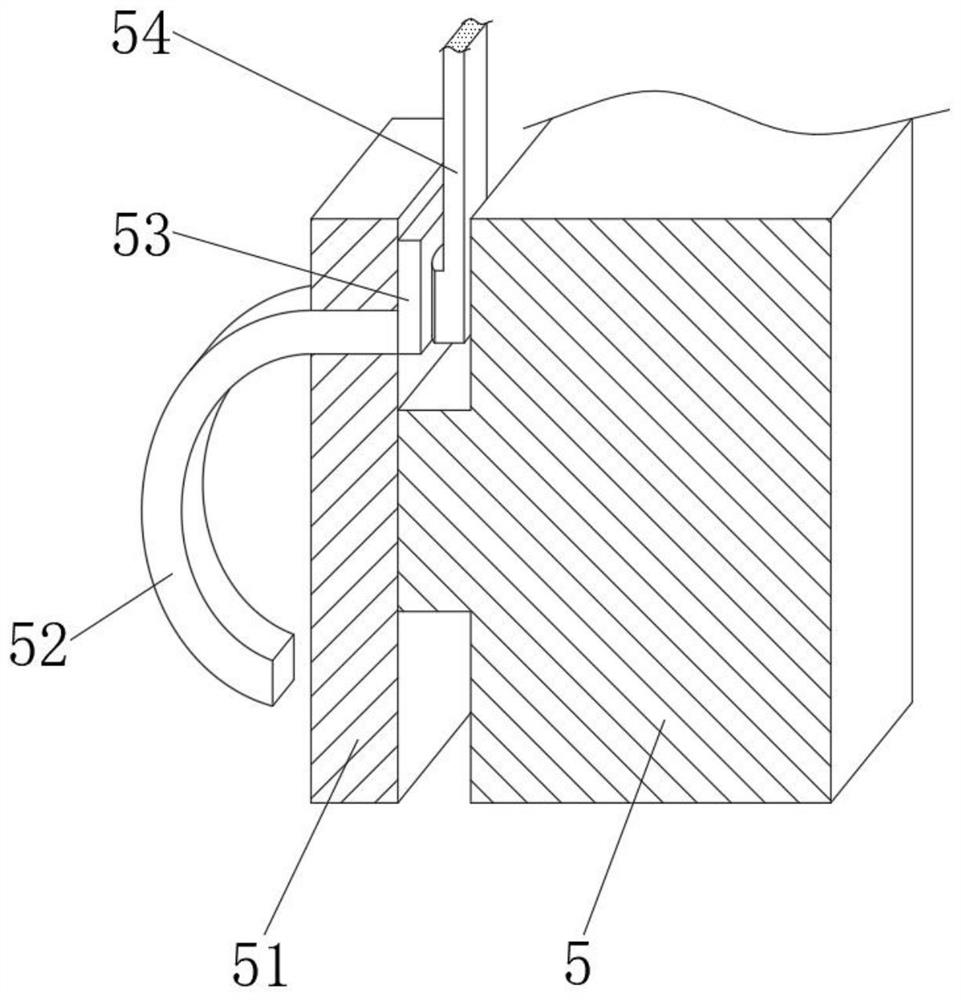

[0026] see Figure 1-4 , the present embodiment provides an electronic component detection and crimping device based on the Internet of Things, including a delivery platform 1 for transporting electronic components, a detection chamber 2 is installed at one end of the delivery platform 1, and the delivery platform 1 moves the electronic components toward The detection chamber 2 is transported, and the detection chamber 2 clamps the electronic components and conducts power-on detection through the two detection belts 5 set inside it. The two are used together to realize the integration of the transportation and detection of electronic components, and further liberate labor.

[0027] Existing automated devices for testing electronic products are mostly appearance testing, X-ray testing and ultrasonic testing, but the power-on testing of electronic products is still at the manual level. To judge the problem of the power-on terminal of the electronic product, it is also necessary...

Embodiment 2

[0047] see Figure 5 , A further improvement has been made on the basis of Embodiment 1: in order to further realize the arrangement of electronic components on the conveyor belt 3 .

[0048] The connecting belt 32 is composed of a plurality of movable blocks 33 , and the adjacent movable blocks 33 are hinged so that the connecting belt 32 can follow the rollers to rotate inside the conveying platform 1 .

[0049] Electronic components with non-cylindrical structures are difficult to move on the top surface of the conveyor belt 3 , so it is necessary to apply an external force to them or obtain a certain amount of kinetic energy.

[0050] Preferably, the side of the movable block 33 is provided with a movable groove 34, and the inside of the movable groove 34 is slidably provided with a finishing plate 35, and an electromagnet and a magnet are arranged between the side of the finishing plate 35 and the inner wall of the movable groove 34 away from the opening end, and the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com