Battery cell forming and laminating equipment

A lamination and cell technology, applied in the field of cell forming lamination equipment, can solve the problems of inconvenient access to cells, uneven feeding, small contact area of pole pieces, etc., to improve appearance flatness and quality, connection Compact, smooth connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

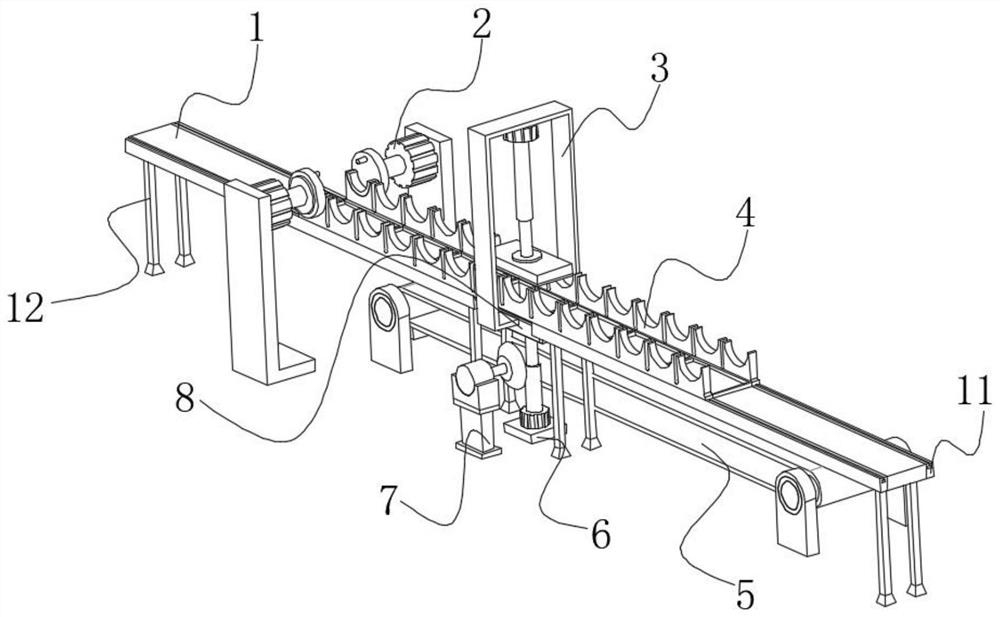

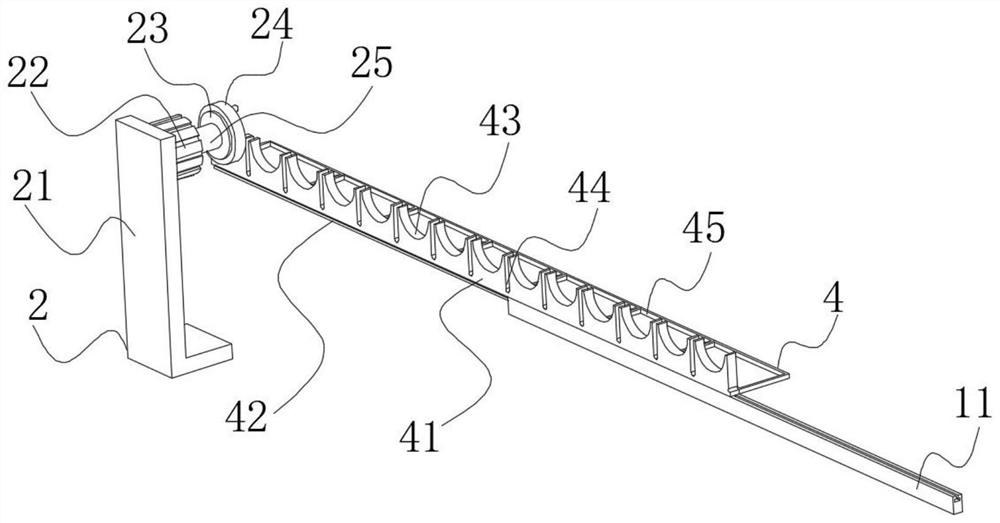

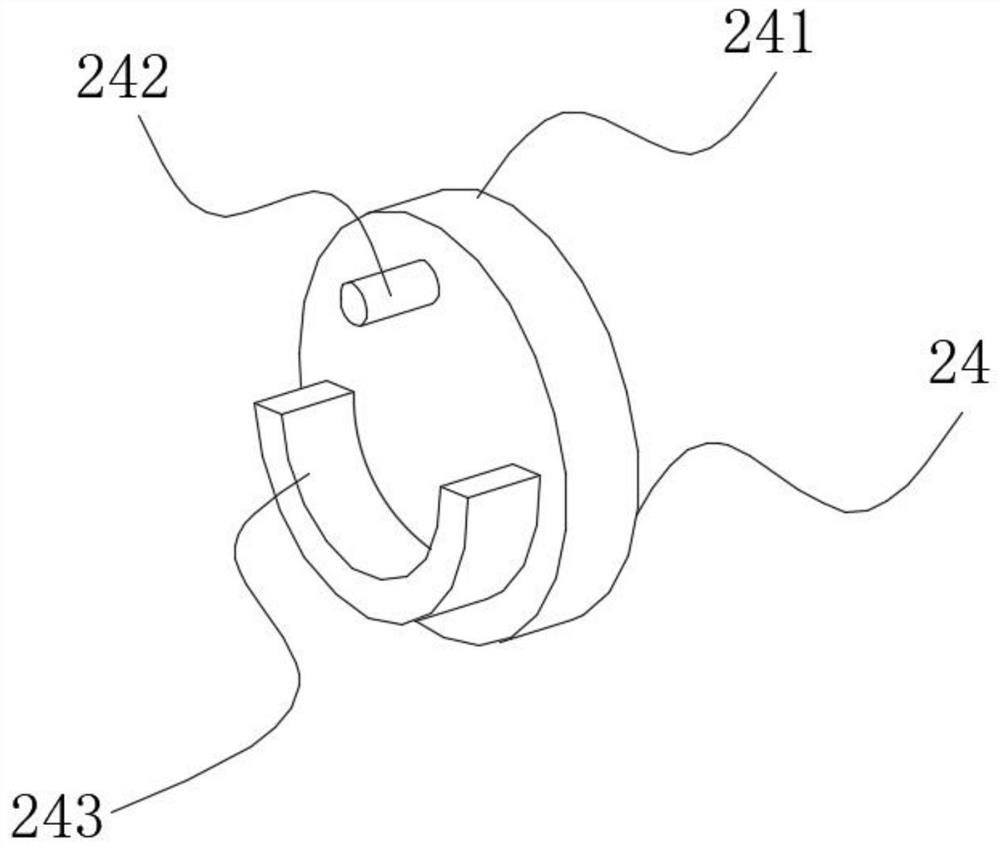

[0037] see Figure 1-9 As shown in the figure, the present invention is a cell forming and stacking equipment, including a return box 8, the front and rear sides of the return box 8 are symmetrically arranged with a feeding assembly 4, and the feeding assembly 4 includes a side plate 41 and a return plate. 45. The lower side of the inner surface of the side plate 41 is connected with a return-shaped plate 45 at equal intervals. The upper surface of the side plate 41 is provided with semi-circular arc grooves 43 and U-shaped grooves 44 at equal intervals from left to right. The inner side of the semi-circular arc groove 43 opened on the upper surface side of the 41 is provided with a driving component 24. The driving component 24 includes a circular plate 241 and a sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com