Polyester melt filter element cleaning equipment

A technology for cleaning equipment and polyester melt, which is applied in the direction of filtration and separation, filter regeneration, separation methods, etc. It can solve the problems of incomplete cleaning and low efficiency of melt filter elements, and achieve short alkaline cleaning operation time and good flow effect , High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

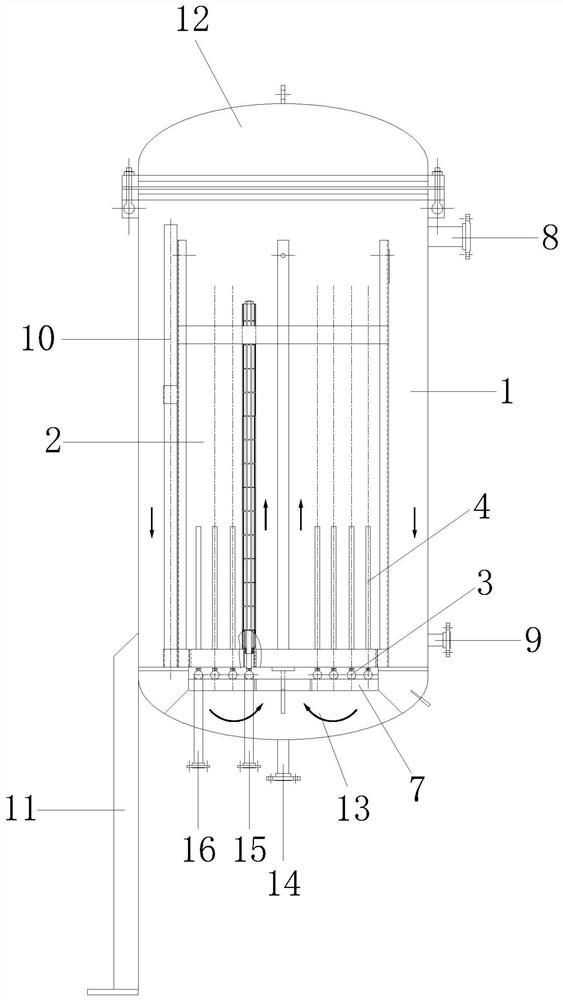

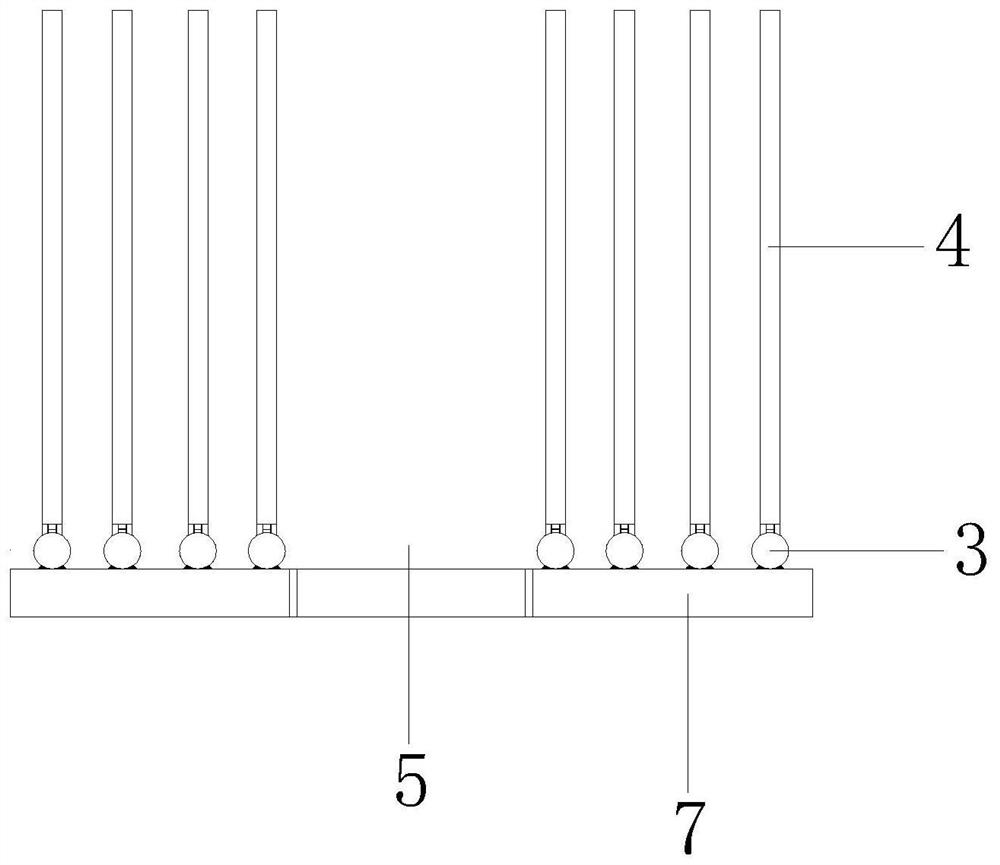

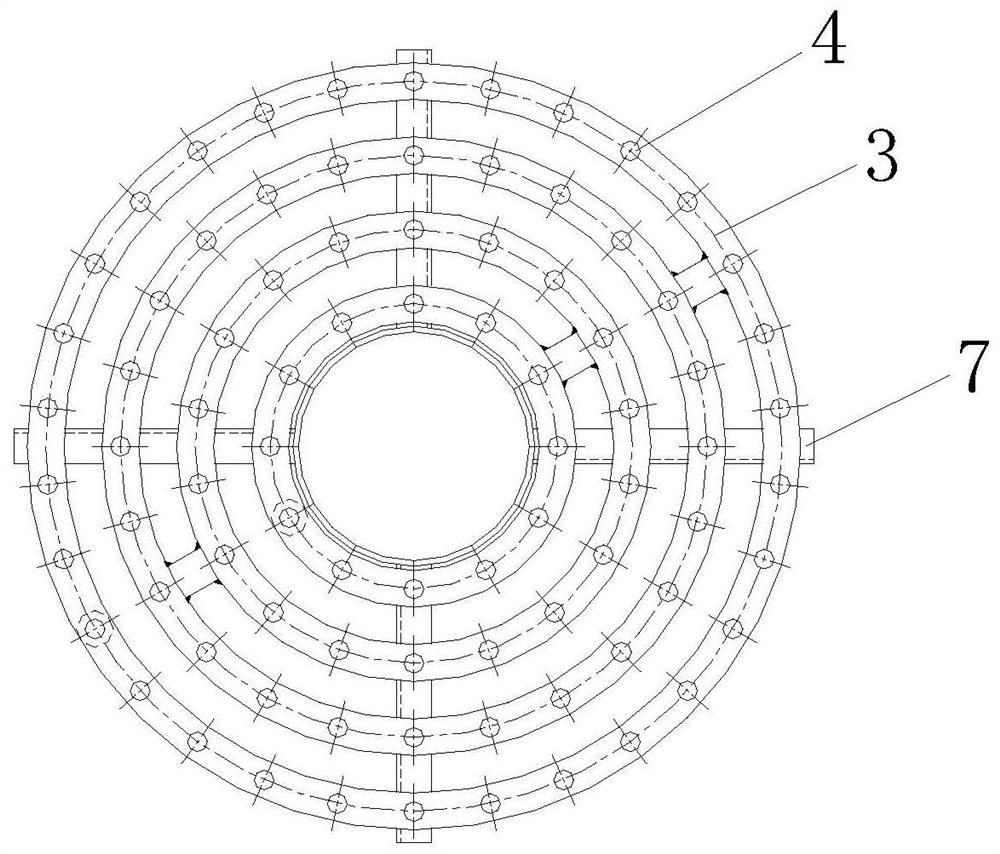

[0028] In order to further understand the content of the present invention, in conjunction with the attached Figure 1-6 And embodiment describe the present invention in detail.

[0029] combined with Figure 1-6 , a kind of cleaning equipment for polyester melt filter elements in this embodiment, comprising an alkali washing cylinder 1, and an alkali washing hanging basket 2 for fixing the opening of the filter element downward, the liquid of the alkali solution in the alkali washing cylinder 1 is The top of the ultra-filter element can be used, and the concentration of the lye is 30%. The outer side of the alkali washing cylinder 1 is welded and fixedly connected with a vertical leg 11, and the top of the alkali washing cylinder 1 is detachably connected with a connecting flange and bolts. The top head 12, the bottom of the alkali cleaning cylinder 1 is welded and fixedly connected with the bottom head 13, the bottom head 13 is provided with a sewage pipe 14, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com