Diphenylphosphinamide silicone oil flame retardant and preparation method thereof

A technology of diphenylphosphine and diphenylphosphine, which is applied in the field of diphenylphosphamide silicone oil flame retardant and its preparation, can solve the problems of single flame retardant element and low flame retardant efficiency, and achieves the The effect of small mechanical properties, high flame retardant efficiency and good compatibility of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

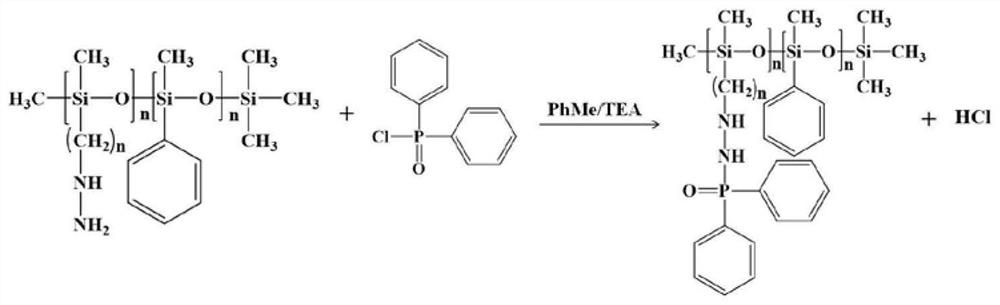

[0037] A kind of diphenylphosphinamide silicone oil flame retardant, its structural formula is as follows:

[0038]

[0039] Such as figure 1 Therefore, its preparation method is as follows:

[0040] S1. Under stirring conditions, stir 25ml toluene, 25g aminophenyl silicone oil and 0.555ml (4.02mmol) acid-binding agent for 10min;

[0041] S2. Slowly add 0.52ml (2.68mmol) of diphenylphosphinyl chloride in 5ml of toluene mixed solution in step S1 at a rate of 15 drops / min, and perform low temperature reaction for 2 hours after the addition;

[0042] S3. After the low-temperature reaction in step S2 is completed, the reaction system is heated, and the temperature is raised to 80° C., and the reaction is continued for 12 hours;

[0043] S4, after step S3 reaction finishes, filter out triethylamine;

[0044] S5. After the filtrate obtained in step S4 is subjected to rotary evaporation to remove toluene, dichloromethane is added for dissolution, and the crude product is dissol...

Embodiment 2

[0047] A kind of diphenylphosphinamide silicone oil flame retardant, its structural formula is as follows:

[0048]

[0049] Such as figure 1 Therefore, its preparation method is as follows:

[0050] S1. Under stirring conditions, stir 25ml toluene, 25g aminophenyl silicone oil and 0.555ml (4.02mmol) acid-binding agent for 10min;

[0051] S2. Slowly add 0.52ml (2.68mmol) of diphenylphosphinic chloride in 5ml of toluene mixed solution in step S1, the dropping rate is 35 drops / min, and carry out low temperature reaction for 4h after dropping;

[0052] S3. After the low-temperature reaction in step S2 is completed, the reaction system is heated, and the temperature is raised to 60° C., and the reaction is continued for 12 hours;

[0053] S4, after step S3 reaction finishes, filter out triethylamine;

[0054]S5. After the filtrate obtained in step S4 is subjected to rotary evaporation to remove toluene, dichloromethane is added for dissolution, and the crude product is disso...

Embodiment 3

[0057] A kind of diphenylphosphinamide silicone oil flame retardant, its structural formula is as follows:

[0058]

[0059] Such as figure 1 Therefore, its preparation method is as follows:

[0060] S1. Under stirring conditions, stir 25ml toluene, 25g aminophenyl silicone oil and 0.555ml (4.02mmol) acid-binding agent for 10min;

[0061] S2. Slowly add 0.52ml (2.68mmol) of diphenylphosphinic chloride in 5ml of toluene mixed solution in step S1, the dropping rate is 50 drops / min, and carry out low temperature reaction for 4h after dropping;

[0062] S3. After the low-temperature reaction in step S2 is completed, the reaction system is heated, and the temperature is raised to 60° C., and the reaction is continued for 18 hours;

[0063] S4, after step S3 reaction finishes, filter out triethylamine;

[0064] S5. After the filtrate obtained in step S4 is subjected to rotary evaporation to remove toluene, dichloromethane is added for dissolution, and the crude product is diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com