Self-foaming delayed solid foam drainage agent and preparation method thereof

A foam drainage agent and self-foaming technology, applied in the direction of chemical instruments and methods, drilling compositions, etc. Possess delay function and other problems to achieve good liquid carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

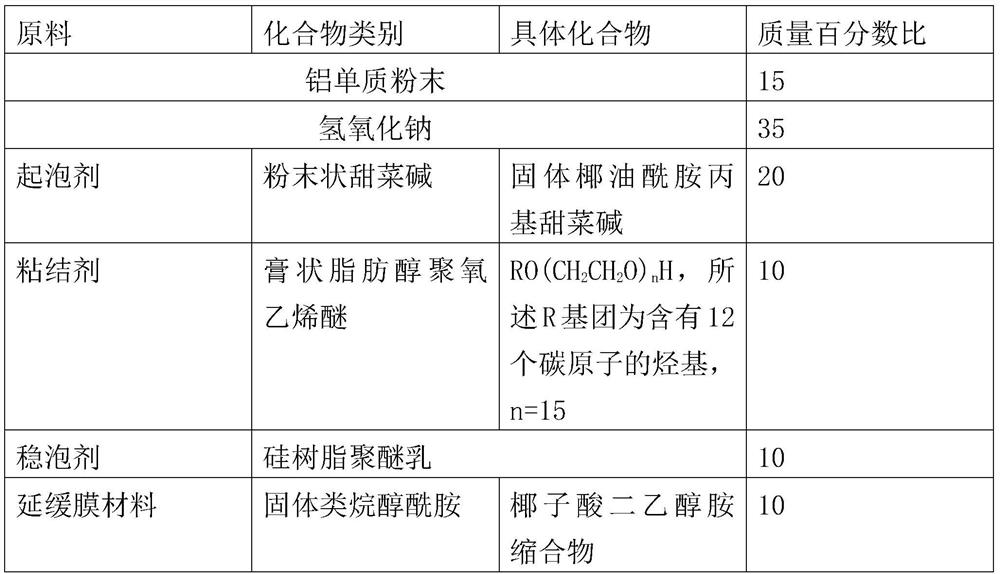

[0028] 1.1 Raw material

[0029] The specific ratio of each chemical component in the solid foam drainage agent prepared in this example is shown in Table 1.

[0030] The specific proportioning ratio of chemical components of table 1 embodiment 1

[0031]

[0032] 1.2 Preparation method

[0033] S1. Preparation of adhesive and delaying film. Dissolve the adhesive completely into a liquid under the heating condition of 60°C, transfer it to a constant temperature and high pressure atomization spraying device and store it at a constant temperature of 60°C for later use; heat the delaying film at 80°C The membrane material is completely dissolved into a liquid, and when the temperature drops to the range of 50-55°C, it is stored at a constant temperature;

[0034] S2. Material mixing. Under the condition of air humidity RH≤30%, weigh the raw materials according to the mass ratio, add aluminum elemental powder, sodium hydroxide and foaming agent to the stirring tank in sequenc...

Embodiment 2

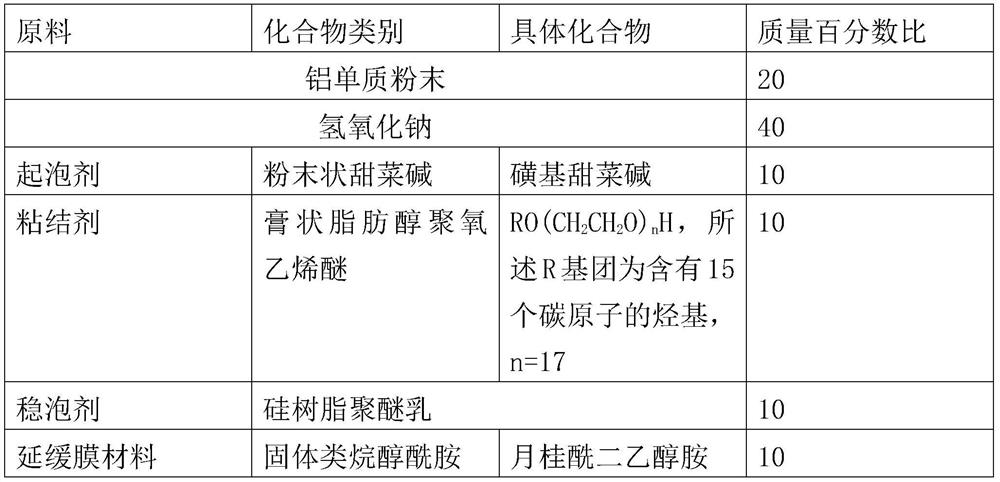

[0038] 2.1 Raw material

[0039] The specific ratio of each chemical component in the solid foam drainage agent prepared in this example is shown in Table 2.

[0040] The specific proportioning ratio of chemical components of table 2 embodiment 2

[0041]

[0042] 2.2 Preparation method

[0043] S1. Preparation of adhesive and delaying film. Dissolve the adhesive into liquid completely under the condition of heating at 80°C, transfer it to a constant temperature and high pressure atomizing spraying device and store it at a constant temperature of 60°C for later use; heat the delaying film at 80°C The membrane material is completely dissolved into a liquid, and when the temperature drops to the range of 55°C, it is stored at a constant temperature;

[0044] S2. Material mixing. Under the condition of air humidity RH≤30%, weigh the raw materials according to the mass ratio, add aluminum elemental powder, sodium hydroxide and foaming agent to the stirring tank in sequence, and...

Embodiment 3

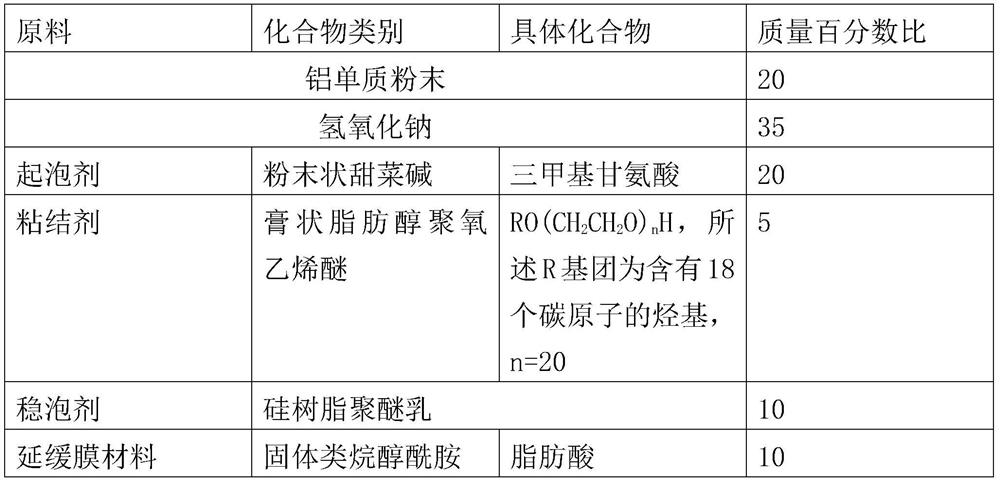

[0048] 3.1 Raw material

[0049] The specific ratio of each chemical component in the foam drainage agent prepared in this example is shown in Table 3.

[0050] The concrete proportioning ratio of the chemical component of table 3 embodiment 3

[0051]

[0052] 3.2 Preparation method

[0053] S1. Preparation of adhesive and delaying film, completely dissolve the adhesive into liquid under the heating condition of 60-80°C, transfer it to a constant temperature and high pressure atomization spraying device and store it at a constant temperature of 60°C for later use; under the heating condition of 80°C Dissolve the delay film material completely into a liquid, and store it at a constant temperature when the temperature drops to the range of 50-55°C;

[0054] S2. Material mixing, under the condition of air humidity RH≤30%, weigh the raw materials according to the mass ratio, add aluminum elemental powder, sodium hydroxide and foaming agent to the stirring tank in sequence, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com