Universal air suction arm with external support

A suction arm and forearm technology, applied in the direction of pipe supports, adjustable connections, pipes/pipe joints/pipe fittings, etc., can solve the problems of limited service life, large ventilation resistance, affecting normal use, etc., and achieve stable performance and hovering Reliable, easy-to-adjust results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

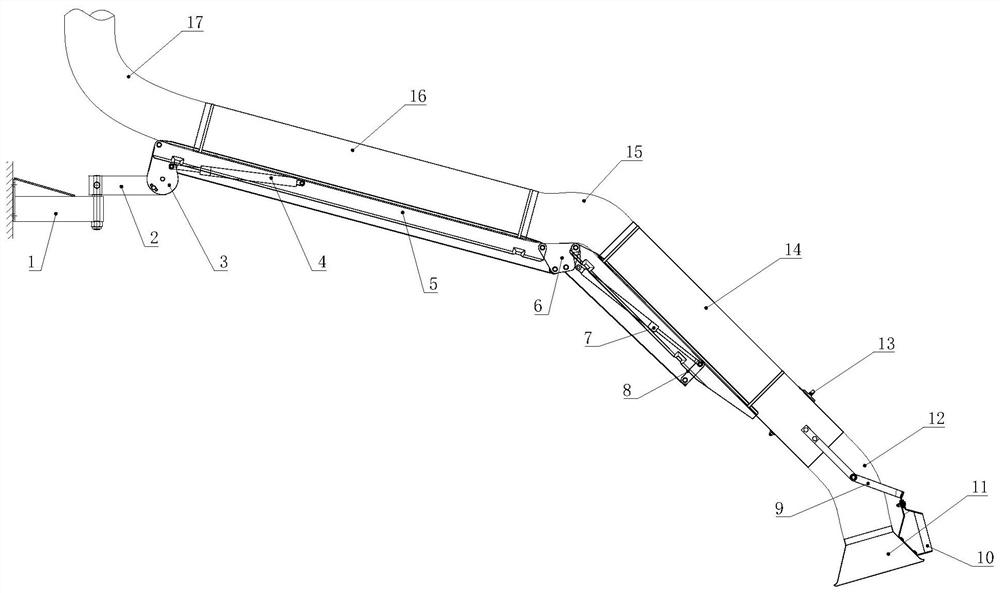

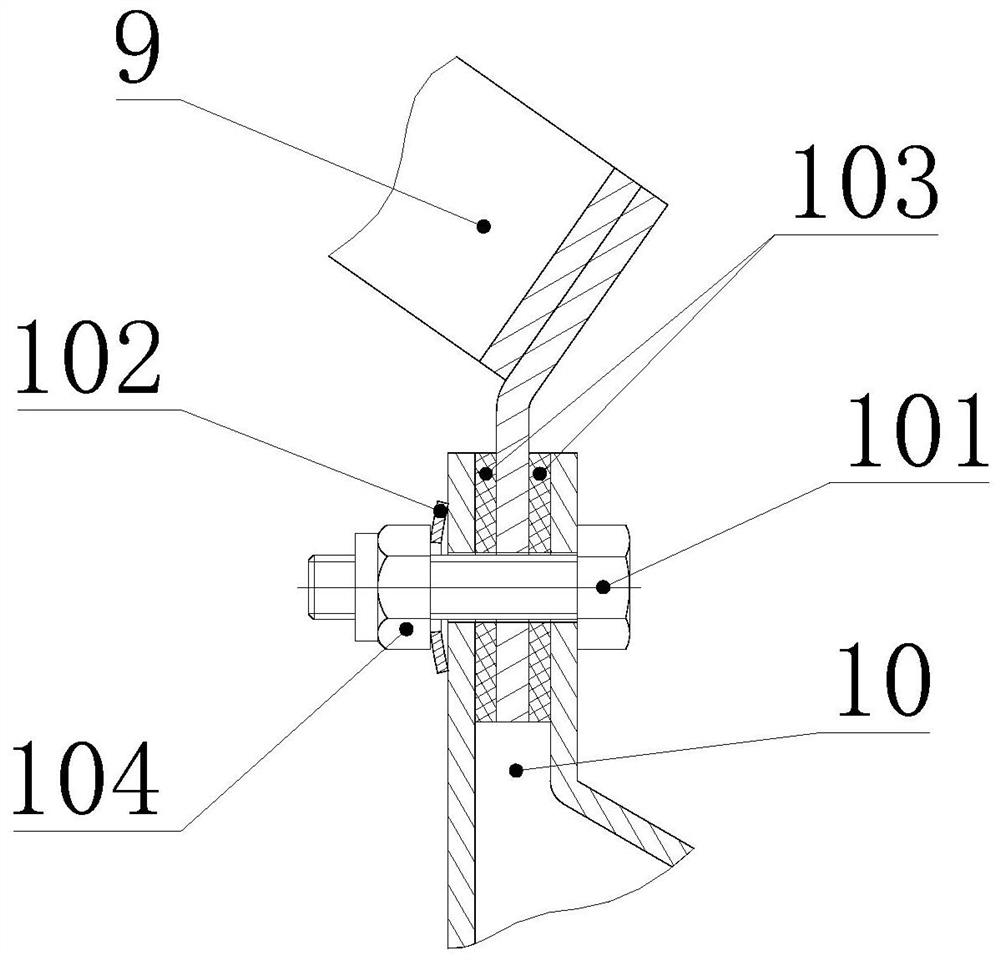

[0033] See figure 1 A hovering external stent universal suction arm, including a fixing structure 1, shoulder cross arm 2, an upper arm bracket 5, and a forearm holder 8, the upper arm bracket 5 is fixed by shoulder joint 3 and shoulder cross arm 2 The upper arm hard tube 16 is attached to the upper arm bracket 5, and the left end of the upper arm hard tube 16 is attached to the right side of the upper arm bracket 5, the front arm bracket 8 is connected to the right side of the upper arm bracket 5 through the elbow joint 6. The front arm hard tube 14 is attached to the upper arm hard tube 14 and the upper arm hard tube 14 and the upper arm hard tube 16 are connected by the elbow hose 15, and the front arm hard tube 14 is connected to the wrist joint 9 and the handle 10 in turn. The hose 12 and the wind cover 11. The upper end of the front arm hard tube 14 is attached to the wind valve knob 13 to control the air volume in the tube.

[0034] The shoulder joint 3 and the upper arm br...

Embodiment 2

[0041] See Figure 9 One way to stand the outer steering carrier, the fixing structure 1 is a rotary flange seat, the shoulder cross arm 2 is a standing cross arm, and the rotary flange is mounted above the horizontal plane, which has a load-bearing, ventilated. And horizontal rotation of three functions, standing transverse arms are used as mechanical connections to rotary flanges. Other structures are in Example 1.

Embodiment 3

[0043] See Figure 10A flange hoisting type external stent universal suction arm, the fixing structure 1 is a rotating flange seat, shoulder cross arm 2 is a lifting bracket type cross arm, rotating flange is hoisted in a downward flangeThe surface, both load, ventilation, and horizontal rotation of three functions, and the hoisting bracket type cross arm is used as a mechanical connection of the suction arm bracket and the rotary flange.Other structures are in Example 1.

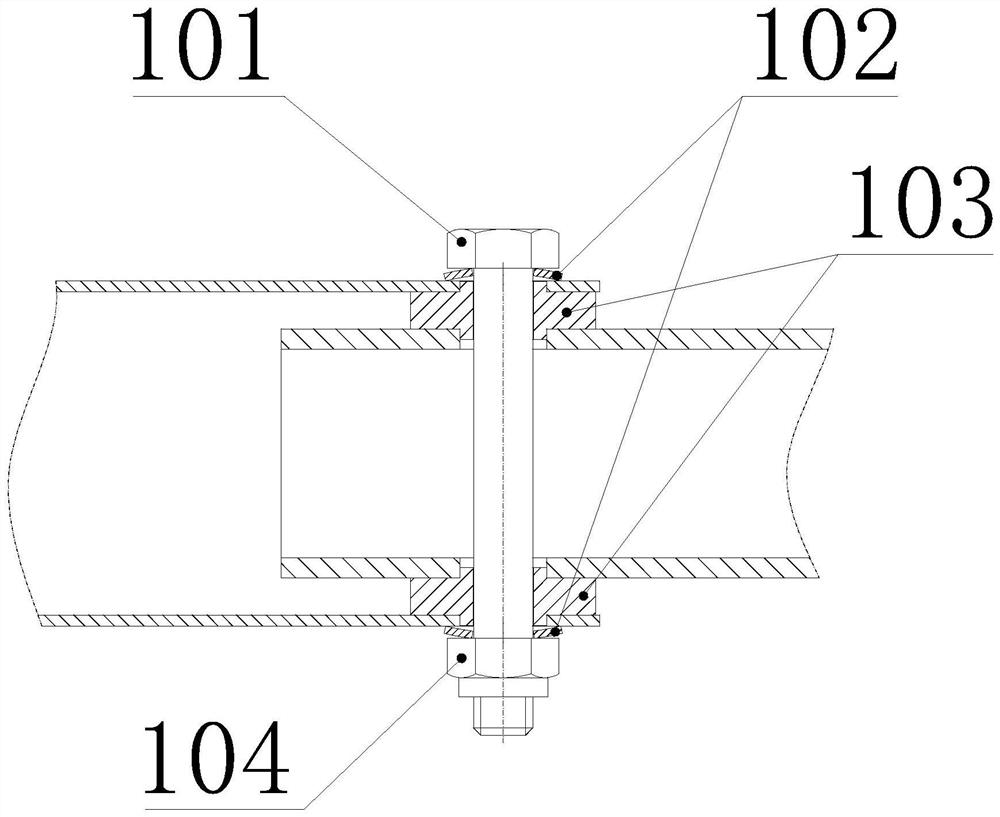

[0044] The shoulder joint 3 of the present invention has an operating range adjustment device, an upper arm air pressure spring 4, and the forward arm springs 7, respectively, in the upper arm bracket 5 and the forearm bracket 8, respectively.There is a wind valve knob 13 on the forear arm hard tube 14 to control the air volume of the tube.The forearm hard tube 14, the wrist hose 12, the wind cover 11 is mechanically connected by the wrist joint 9, and the wrist joint 9 is a 10,000-year-in-band, which can rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com