Low-temperature-resistant electrolyte as well as preparation method and application thereof

An electrolyte and anti-low temperature technology, which is applied in the field of electrolyte, can solve problems such as failure to work normally, increase in viscosity of the electrolyte, and decrease in conductivity, and achieve the effects of ensuring charge and discharge performance, improving low-temperature conductivity, and excellent low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

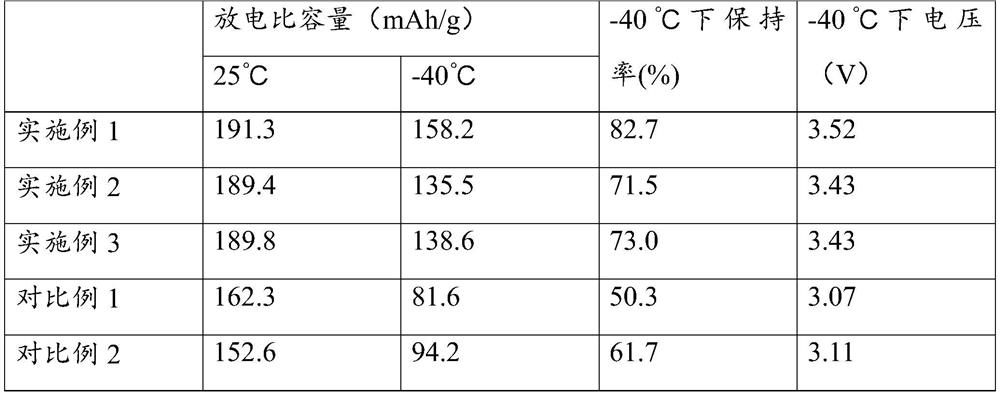

Examples

Embodiment 1

[0038] In an environment with a humidity of 750ppm, take 42ml of a mixed solvent of dimethyl carbonate and diethyl carbonate, add it to 16ml of a mixed solvent of ethyl methyl carbonate and propyl methyl carbonate, and then add 0.8g of fluoroethylene carbonate ester and 0.6g of succinonitrile, then add 8g lithium hexafluorophosphate, 1.5g lithium difluorophosphate, 1g lithium oxalate phosphate, 0.8g dimethyl fumarate and 0.3g hexamethyldisilazane, and stir to obtain the obtained Anti-low temperature electrolyte.

Embodiment 2

[0040] In an environment with a humidity of 750ppm, take 24ml of a mixed solvent of dimethyl carbonate and diethyl carbonate, add it to 34ml of a mixed solvent of ethyl methyl carbonate and propyl methyl carbonate, and then add 0.8g of fluoroethylene carbonate ester and 0.6g of succinonitrile, then add 8g lithium hexafluorophosphate, 1.5g lithium difluorophosphate, 1g lithium oxalate phosphate, 0.8g dimethyl fumarate and 0.3g hexamethyldisilazane, and stir to obtain the obtained Anti-low temperature electrolyte.

Embodiment 3

[0042] In an environment with a humidity of 750ppm, take 10ml of a mixed solvent of dimethyl carbonate and diethyl carbonate, add it to 48ml of a mixed solvent of ethyl methyl carbonate and propyl methyl carbonate, and then add 0.8g of fluoroethylene carbonate ester and 0.6g of succinonitrile, then add 8g lithium hexafluorophosphate, 1.5g lithium difluorophosphate, 1g lithium oxalate phosphate, 0.8g dimethyl fumarate and 0.3g hexamethyldisilazane, and stir to obtain the obtained Anti-low temperature electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com