Low-temperature-resistant lithium ion battery non-aqueous electrolyte and lithium ion battery

A lithium-ion battery and non-aqueous electrolyte technology, which is applied in the field of lithium-ion batteries, can solve the problems of poor low-temperature cycle and room temperature cycle performance, battery cycle diving, and lowering, to overcome temperature stability, reduce reaction, and low impedance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

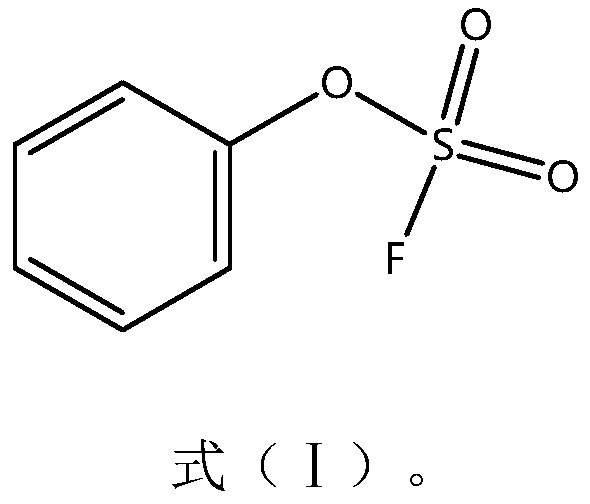

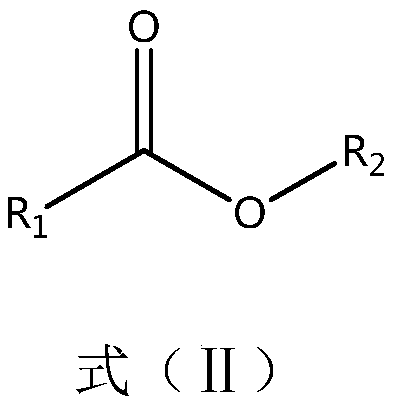

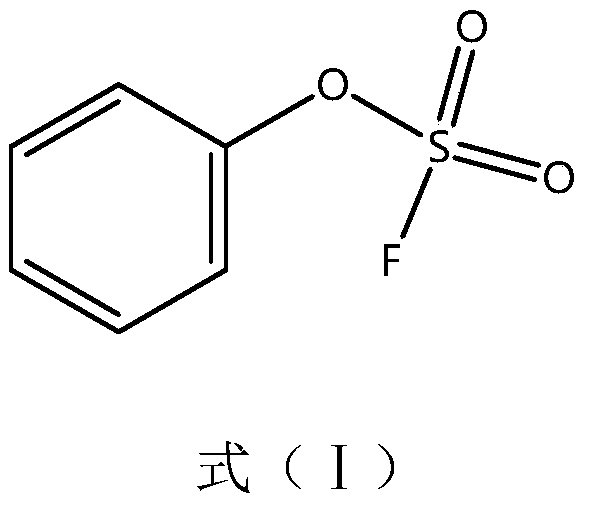

Image

Examples

Embodiment 1

[0031] Electrolyte preparation steps: In a glove box filled with argon, ethylene carbonate, propylene carbonate, ethyl methyl carbonate and ethyl propionate are prepared according to the mass ratio of EC:PC:EMC:EP=20:10:10: 60 for mixing, then slowly add 12.5wt% lithium hexafluorophosphate to the mixed solution, and finally add 0.2wt% vinylidene carbonate (VC) based on the total weight of the electrolyte, and 1.0wt% 1,3-propanesulfonate based on the total weight of the electrolyte Acid lactone (PS), 2.0wt% fluoroethylene carbonate (FEC) based on the total weight of the electrolyte and 0.8wt% lithium difluorophosphate (LiPO 2 f 2 ), after stirring uniformly, obtain the lithium-ion battery electrolyte of embodiment 1.

[0032]The prepared lithium-ion battery electrolyte was injected into the fully dried artificial graphite material / lithium cobaltate (4.2V) battery. After the battery was left at 45°C, formed by high-temperature fixtures and sealed twice, it was routinely divided...

Embodiment 2-13

[0033] Embodiment 2-13 and comparative example 1-6

[0034] As shown in Table 1, in Examples 2-13 and Comparative Examples 1-6, except that the composition ratio of the components of the electrolyte solution is added as shown in Table 1, the others are the same as in Example 1.

[0035] Table 1 Embodiment 1-13 and the composition and proportioning ratio of the electrolyte of comparative examples 1-6

[0036]

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com