Submersible pump rotor with high stability

A submersible pump and stability technology, which is applied in the field of submersible pump rotors, can solve problems such as unsatisfactory use requirements, simplification of functions, and impact on stability, and achieve the effects of saving resources, reducing consumption, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

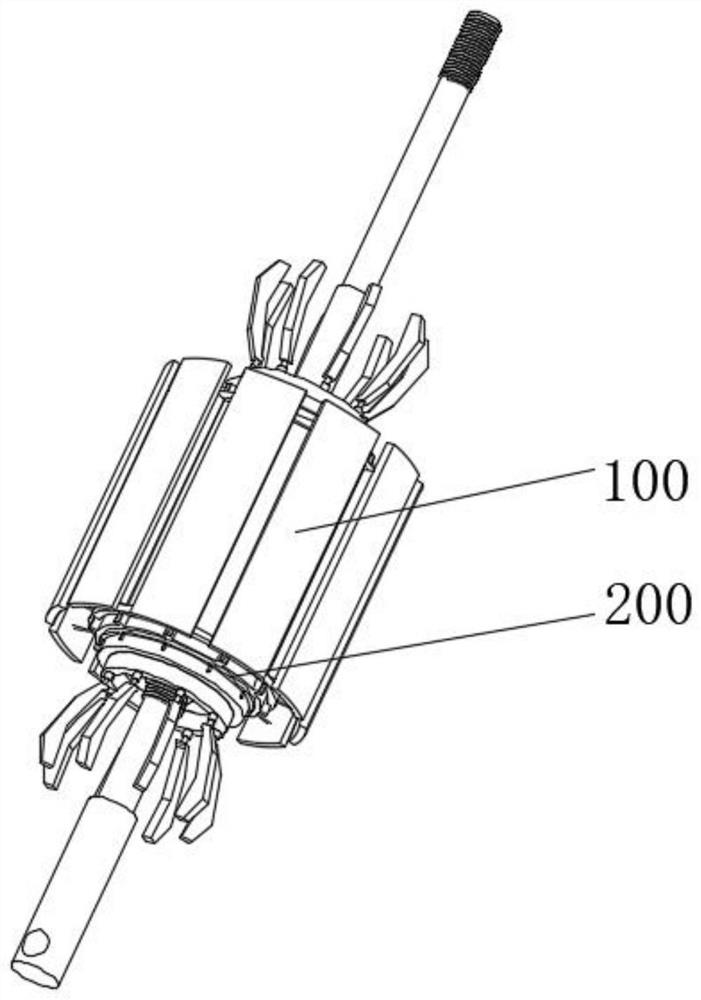

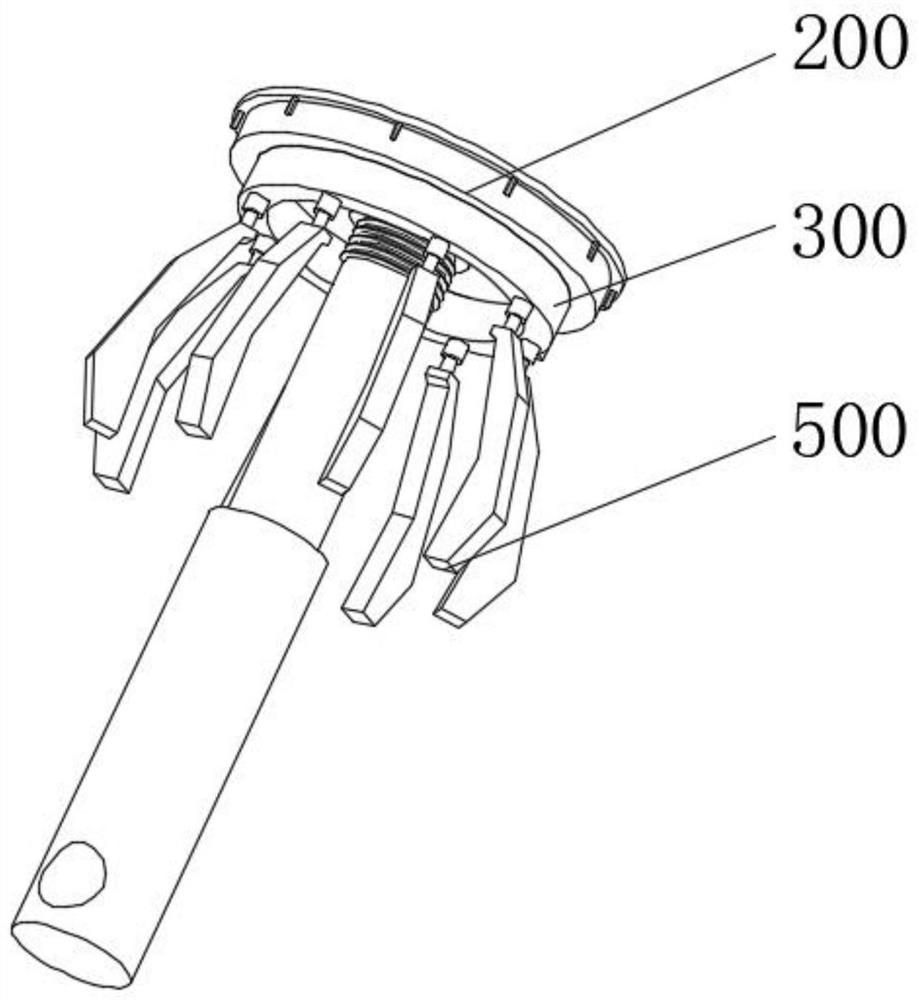

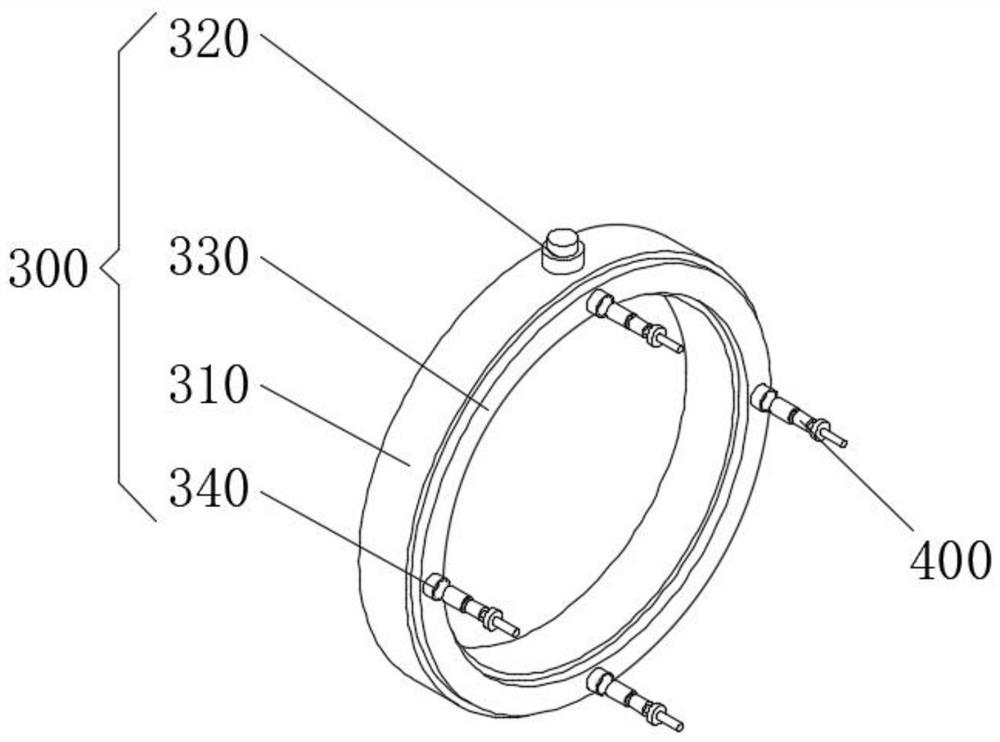

[0047] see Figure 1-9 As shown, the present invention is a submersible pump rotor with high stability, including a rotor mechanism 100, a stabilizing mechanism 300, a volume control mechanism 400 and a heat dissipation mechanism 500. The end of the rotor mechanism 100 is connected with a shaft seat 200, and the shaft seat 200 The middle part is fixedly connected with a stabilizing mechanism 300 , and a set of oil supply tanks 310 included in the stabilizing mechanism 300 is penetrated with a stud 320 in the upper middle, and the outer end of the cover plate 330 in the middle of the inner end of the fuel supply tank 310 is equidistantly penetrated with oil supply pipes 340 ;

[0048] The inner wall of the oil supply tank 310 is equidistantly connected with the volume control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com