Heat dissipation structure of servo driver

A technology of a servo drive and a heat dissipation structure, applied in the field of servo drives, can solve the problems of short circuit of the servo drive, affecting the heat dissipation effect of the equipment, and low heat dissipation efficiency, and achieve the effect of improving the heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

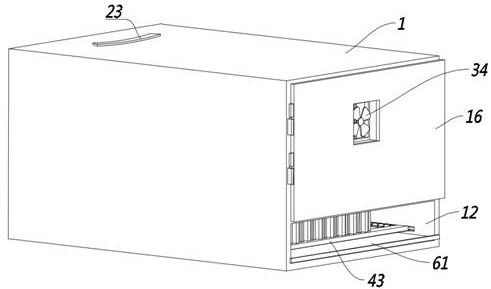

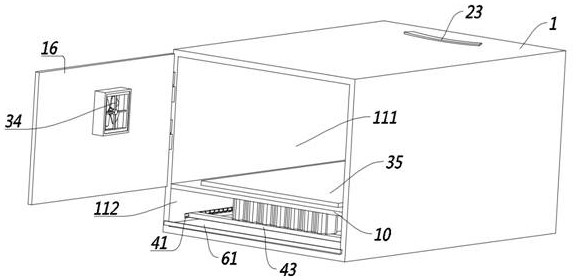

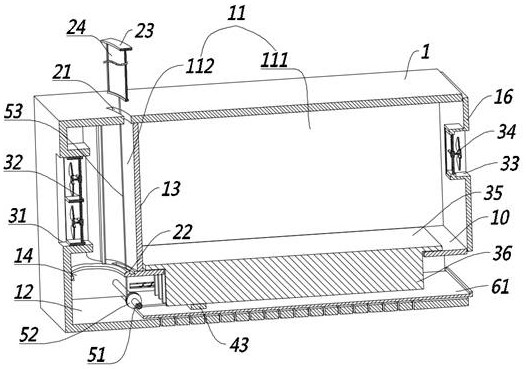

[0032] This embodiment provides a heat dissipation structure of the servo drive, which mainly uses the heat dissipation of the servo drive to increase the heat dissipation efficiency of the heat dissipation plate, prevent dust from interfering with the equipment, and simplify the way of cleaning the heat sink dust.

[0033] Including the casing 1, the inner cavity of the casing 1 is fixed with a partition 10 separating the inner cavity of the casing 1 into a first cavity 11 and a second cavity 12, and the partition 10 is provided with The first cavity 11 is divided into the windshield assembly of the driver installation chamber 111 and the air inlet chamber 112, the windshield assembly includes an arc-shaped windshield 13 fixed on the partition 10, and the two windshields 13 The air inlet chamber 112 is provided with a dust filter mechanism extending out of the upper end surface of the casing 1, and the partition 10 is provided with a connection between the air inlet chamber 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com