Thermal activation force-electricity synergistic dressing for accelerating wound healing and preparation method

A wound healing and thermal activation technology, applied in dressings, electrotherapy, viscous dressings, etc., can solve the problems of promoting wound healing, single, no electro-mechanical co-stimulation, etc., to inhibit the formation of scabs, promote the healing process, and promote the wound surface. closed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

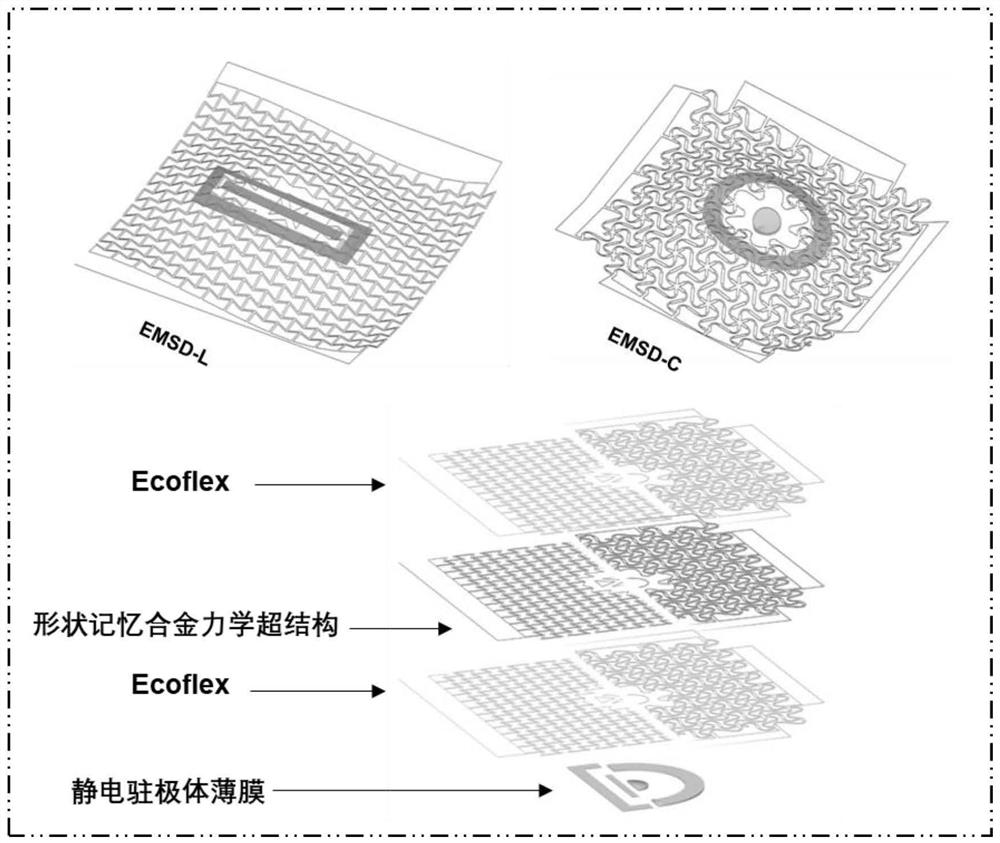

[0051] Taking Lidian synergistic dressings adapted to linear wounds as an example, the flexible material is Ecoflex material.

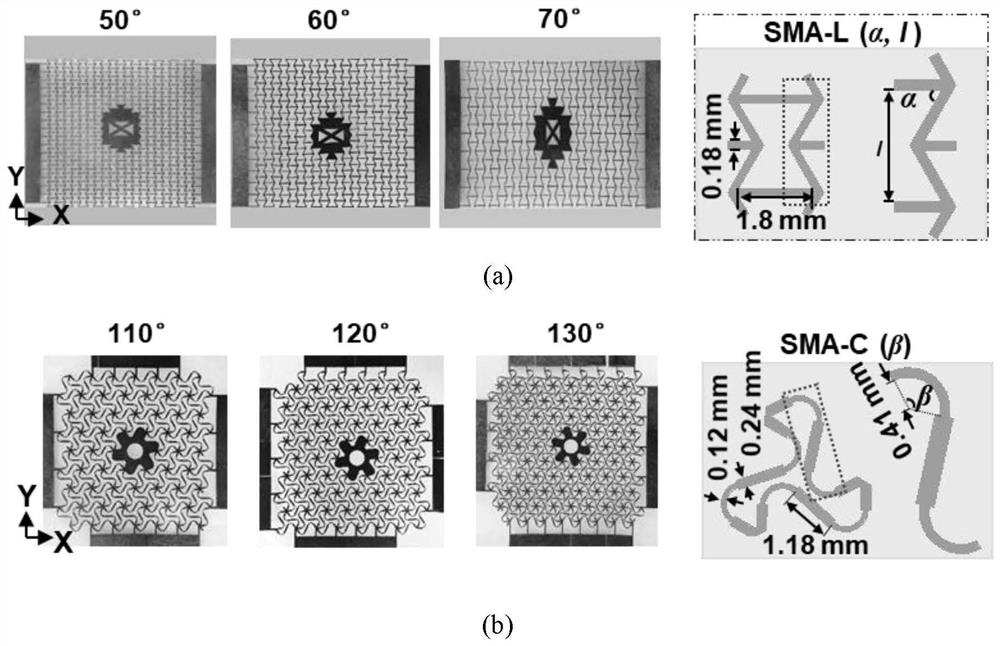

[0052] The unit structure of the mechanical superstructure mesh skeleton pattern area of the electromechanical synergistic dressing is as follows: figure 2 (a) As shown in the figure on the right, the unit structure is an up-down and left-right axisymmetric figure, which is specifically obtained by connecting two transverse M openings, named shape memory alloy mesh L-type (SMA-L). When the bottom side length is 1.8mm and the line width is 0.18mm, the unit structure can be adjusted by adjusting the angle α between the bottom side length and the hypotenuse and the height l between the upper and lower bottom sides.

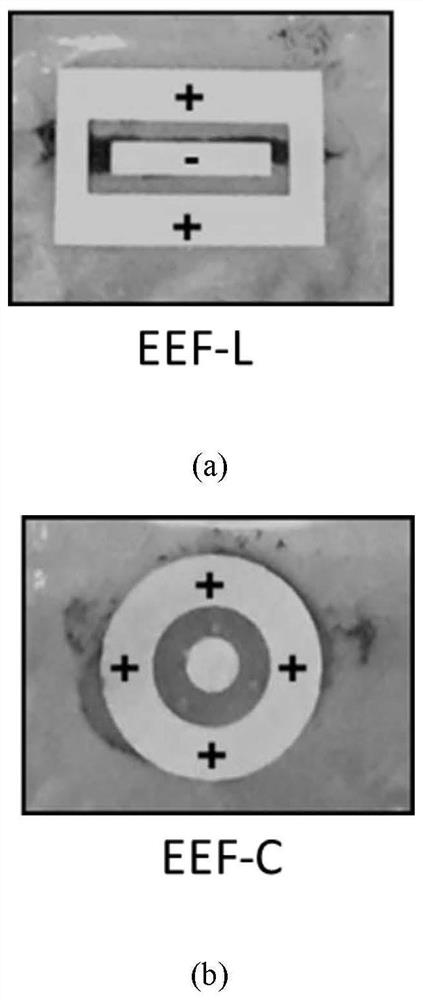

[0053] Schematic diagram of electrostatic electret film structure of Lidian synergistic dressing image 3 As shown in (a), the positive electrode area separated by the electrostatic electret film is a concentric rectangular ring, and the...

Embodiment 2

[0057] Take the application of Lidian synergy dressing for circular wounds as an example.

[0058] The unit structure of the mechanical superstructure mesh skeleton pattern area of the electromechanical synergistic dressing is as follows: figure 2 (b) As shown in the figure on the right, the unit structure is a rotationally symmetrical figure, which is a ring structure obtained by connecting the basic figures end to end. The basic figures are S-like, consisting of three straight lines and two circular arcs alternately connected , named shape memory alloy mesh type C (SMA-C). When the width and radius of the arc are 0.12mm and 0.41mm respectively, and the width and length of the straight line are 0.24mm and 1.18mm, the corresponding angle β of the arc can be adjusted to adjust the unit structure.

[0059] Schematic diagram of electrostatic electret film structure of Lidian synergistic dressing image 3 As shown in (b), the positive electrode area separated by the electrost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com