Construction method of roller coaster upside-down type embedded structure

A construction method and roller coaster technology, applied in the field of construction engineering, can solve the problems of occupying building area, difficult to realize, and limited space, so as to ensure installation precision and accuracy, enhance immersion and stimulation, and save space and materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

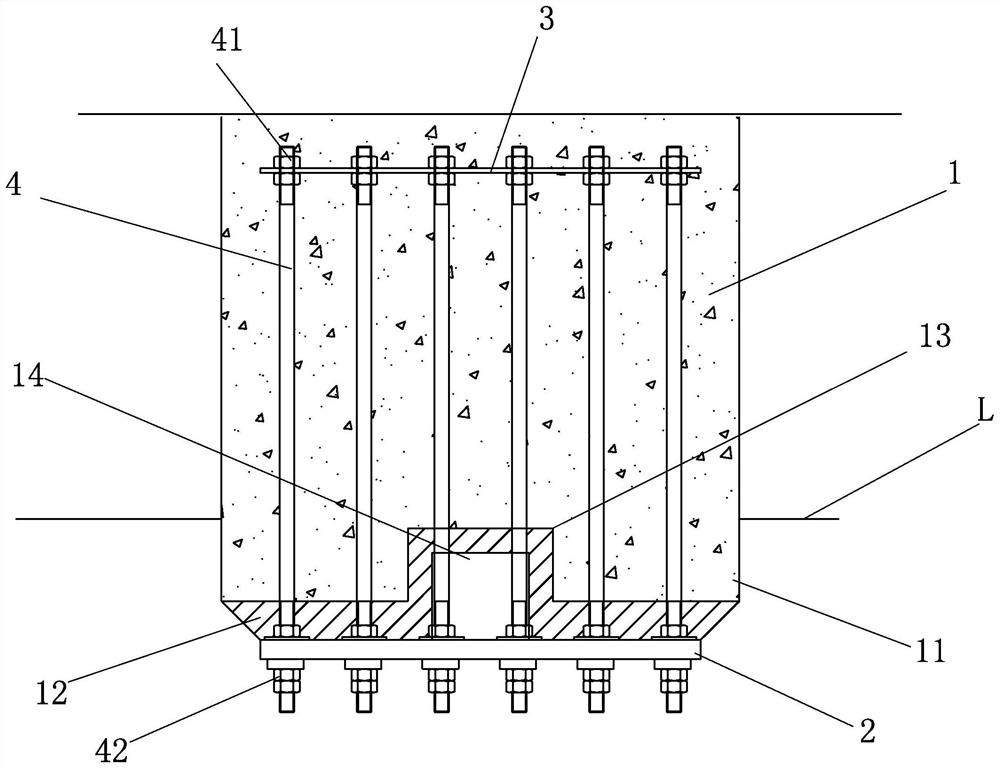

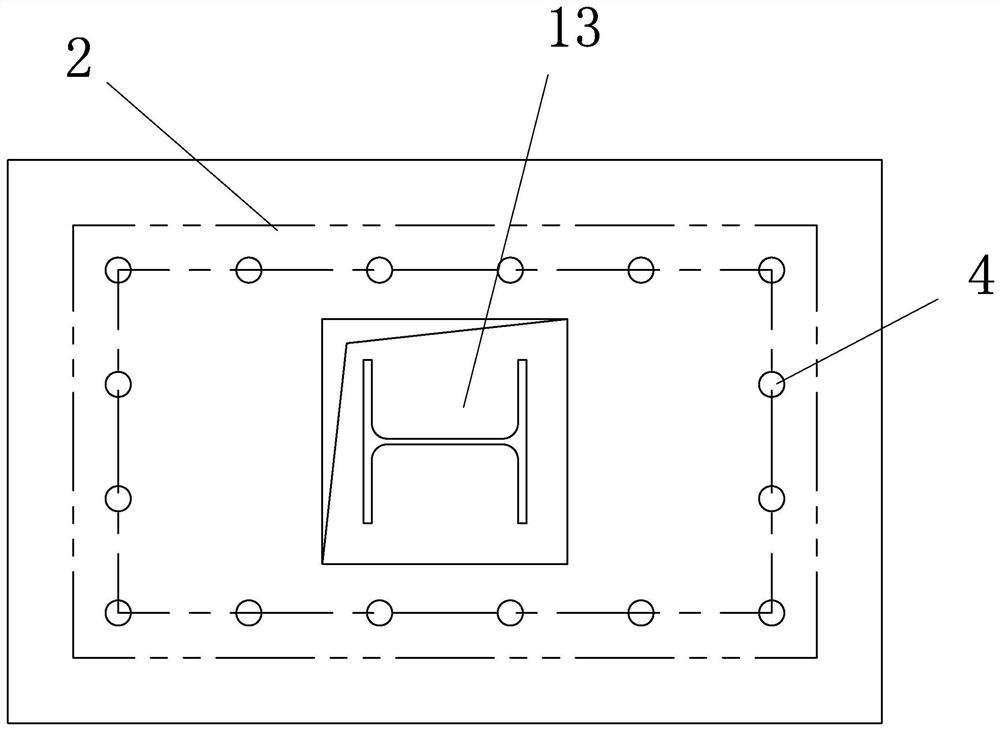

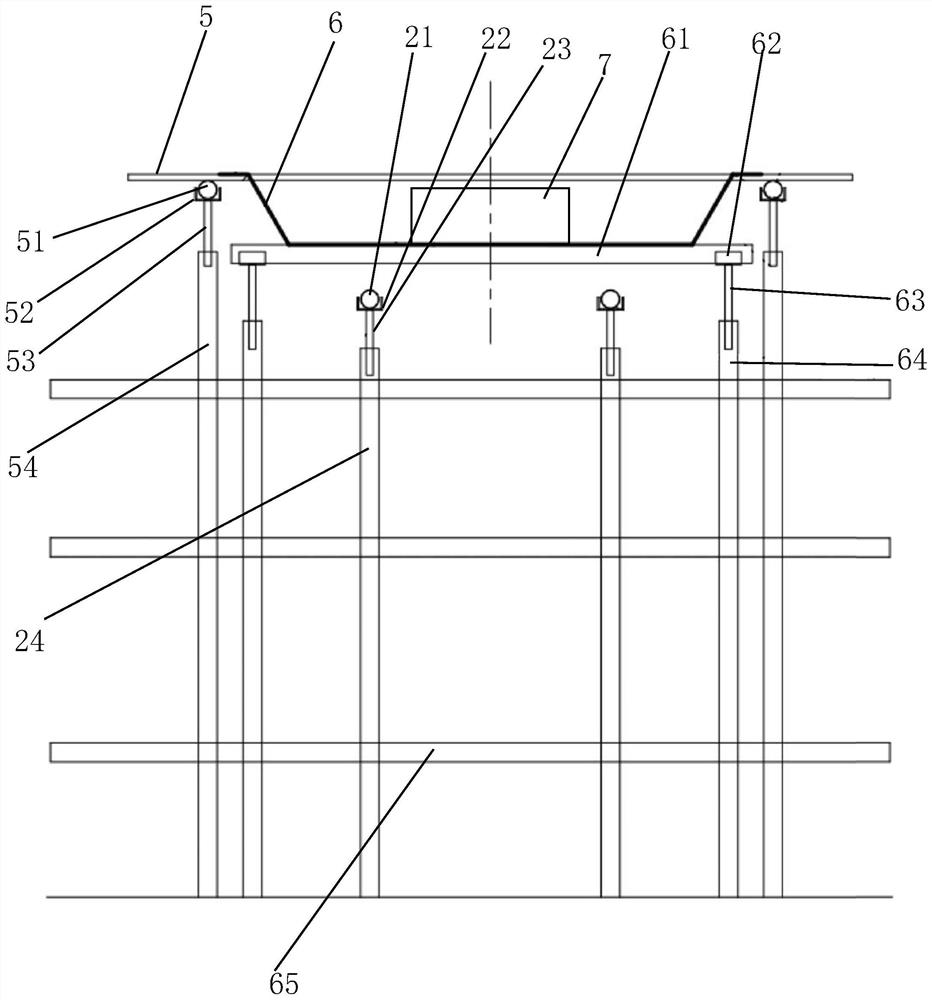

[0040] Such as figure 1 , figure 2 As shown, the present invention provides a roller coaster upside-down pre-embedded structure, including a building roof beam 1, and L in the figure is the bottom surface of the building roof beam. The bottom of the roof beam 1 of the building extends downwards with several bosses 11, which are lower than the bottom surface L of the roof beam of the building. The bottom surface of each boss 11 is poured with a secondary grouting layer 12, and the bottom surface of the secondary grouting layer 12 is provided with a pre-buried Bottom plate 2, the embedded top plate 3 is arranged above the inside of the boss 11, and the embedded top plate 3 and the embedded bottom plate 2 are connected by several vertical screw rods 4, and the top and bottom of each screw rod 4 are respectively provided with two top nuts 41 and two bottom nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com