Assembled steel structure check sluice

A technology of steel structure and control gates, applied in ship locks, ship lifting devices, water conservancy projects, etc., can solve problems affecting shipping and economic benefits, long construction time, and dependence on weather effects, so as to improve progress and economic benefits and save space and materials, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

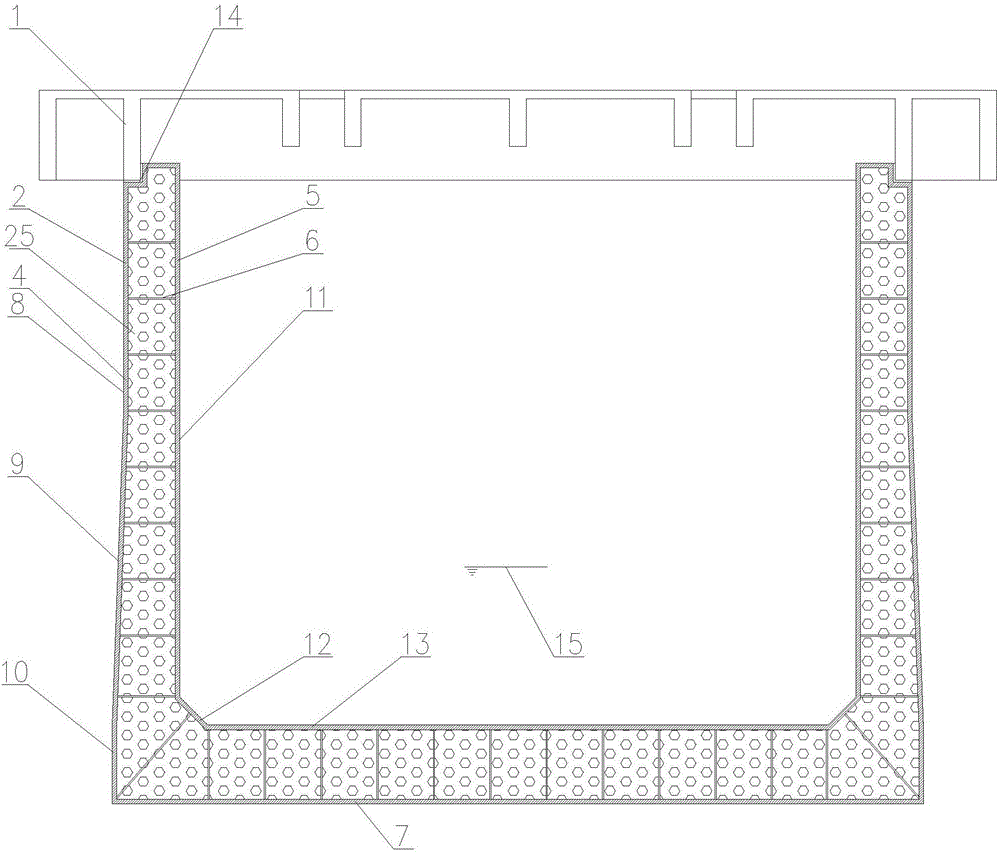

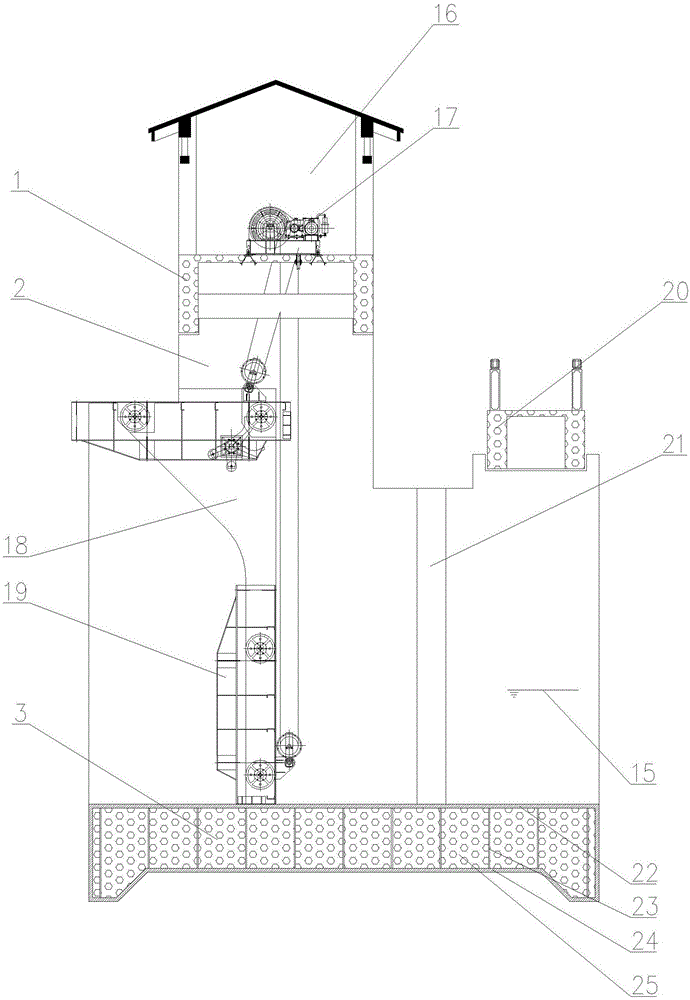

[0018] As shown in the figure, an assembled steel structure control gate; including a working bridge 1, a vertical steel structure 2 and a supporting floor steel structure 3; the working bridge 1 is located above the vertical steel structure 2, and The vertical steel structure 2 is matched and fixedly connected, and is used as a load-bearing foundation for the staff; the supporting floor steel structure 3 is located below the vertical steel structure 2, and is connected with the vertical steel structure 2. Structure 2 is fixedly connected and used to carry the entire cut-off gate.

[0019] Further, the vertical steel structure 2 includes an outer plate 4, an inner plate 5 and a supporting plate 6; the outer plate 4 is located on the outside of the control gate, and is used as the outer surface of the entire control gate from top to bottom; The inner plate 5 is located on the inner side of the damper, and is used for the inner wall of the entire damper from top to bottom; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com