Fabricated fully-prefabricated stair and fabricated stair building

A prefabricated and stair technology, applied in stairs, buildings, building structures, etc., can solve the problems of low utilization rate of formwork, heavy weight of precast concrete stairs, etc., achieve high prefabrication rate, convenient transportation and hoisting, structural earthquake resistance and economical Effects of Sexual Help

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

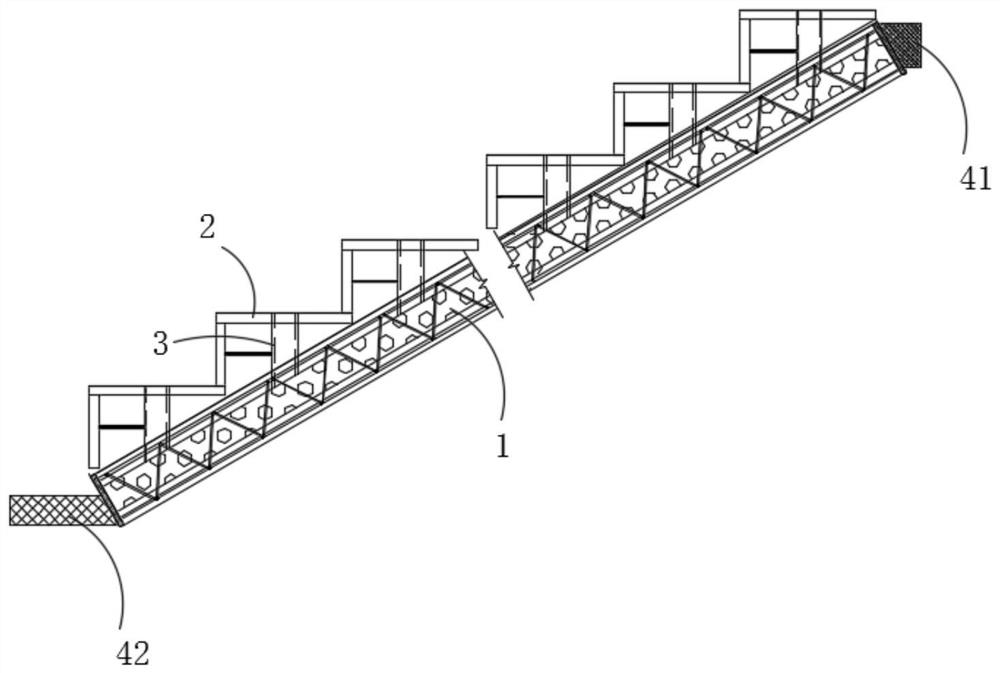

[0051] Such as figure 1 As shown, the prefabricated fully prefabricated staircase disclosed in this embodiment includes a step plate 1, a tread plate 2, a step plate connector 3 and a step plate connector. The step plate 2 is located above the step plate 1 and is connected with the step plate 1 through the step plate connector 3 . Both ends of the stair plate 1 are provided with stair plate connectors, which are used to connect the stair plate 1, the platform plate 5 and the platform beam 6 to coordinate the deformation of the three.

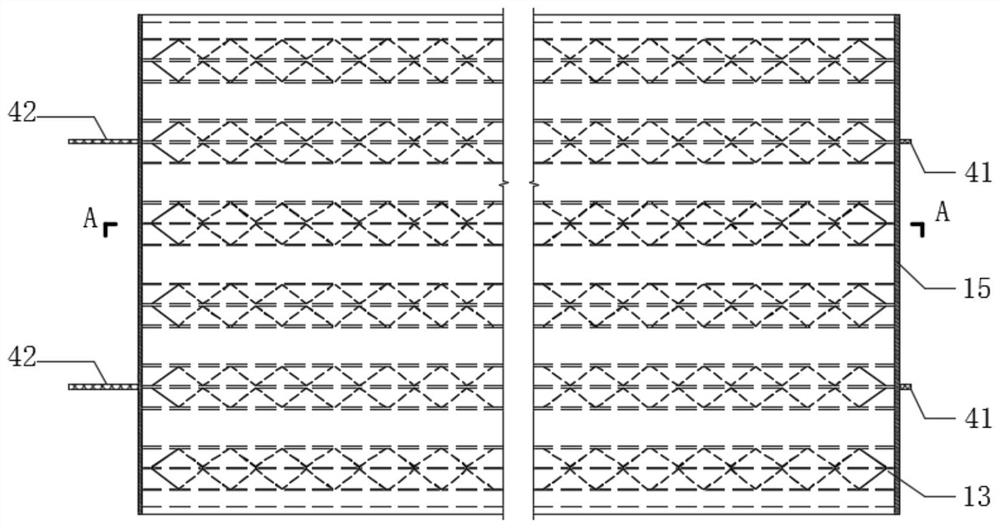

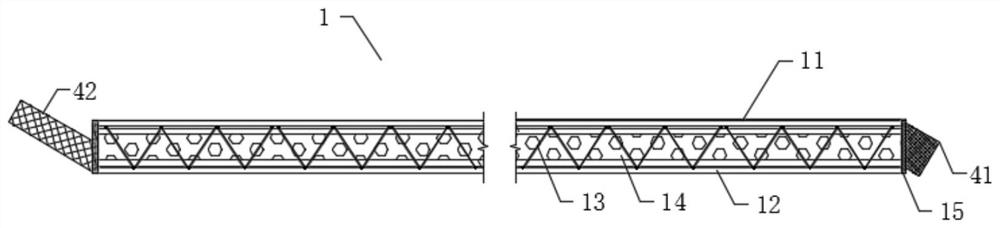

[0052] Such as Figure 1-Figure 3 As shown, the stair slab 1 is a sandwich slab, specifically including a face plate 11 , a bottom plate 12 , a steel bar truss 13 , a filling material 14 and a head steel plate 15 . The filling material 14 is located between the face plate 11 , the bottom plate 12 and the head steel plate 15 . The steel bar truss 13 is anchored to the face plate 11 and the bottom plate 12, and is used for bearing the shear for...

Embodiment 2

[0070] In the present embodiment, the thickness of the stair section plate 1 is 100-500mm, wherein, the steel bar cover thickness of the panel 11 and the base plate 12 is 5-10mm, and the steel bar cover thickness of the common concrete slab is 15mm; the panel 11 and the base plate 12 thickness can be 20mm-30mm, while the minimum thickness of ordinary concrete slabs is 50mm.

[0071] The production process of the stair slab 1 is the same as that of the floor slab, and both adopt one-time molding, which will not be repeated here. The dimensional change of the step slab 1 has low requirements on the formwork, and can be produced with a simple formwork.

[0072] It is worth mentioning that ordinary UHPC can be used as the tread plate 2 as the fair-faced concrete finish, without reinforcement, and the thickness of the plate can be 10-30mm, which can greatly reduce the weight of the tread plate. Of course, the step plate 2 can also adopt decorative UHPC, imitation stone, etc., so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com